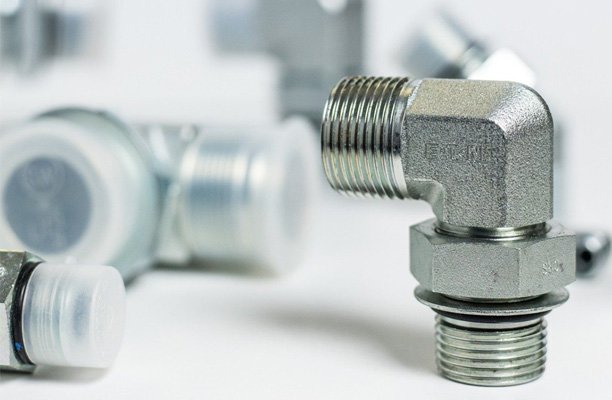

If you’ve ever wondered where Eaton hydraulic fittings are made and whether it matters, you’re not alone. These essential components play a crucial role in various industries, from construction to manufacturing. Let’s dive into where Eaton makes these fittings, who their suppliers are, and more.

I. Where Are Eaton Hydraulic Fittings Made?

Eaton hydraulic fittings are manufactured in several countries, with major production facilities located in the United States and China. As a global company, Eaton leverages its widespread manufacturing network to serve different markets effectively and efficiently.

In the United States, Eaton operates multiple factories dedicated to producing hydraulic fittings. These U.S.-based facilities are known for their strict quality control measures and advanced manufacturing techniques, ensuring that the products meet the high standards required for industries like construction, agriculture, and heavy machinery. Many customers prefer products labeled “Made in the USA” due to the perception of higher quality and reliability.

However, Eaton also has a significant manufacturing presence in China, where the company operates several state-of-the-art facilities. These include locations in:

- Jining, Shandong Province

- Shanghai

- Hangzhou, Zhejiang Province

- Wuxi, Jiangsu Province

- Suzhou, Jiangsu Province

- Xi’an, Shaanxi Province

- Chengdu, Sichuan Province

- Nanjing, Jiangsu Province

- Baoji, Shaanxi Province

Each of these sites is equipped with modern machinery and follows the same rigorous quality standards as Eaton’s U.S. plants. Manufacturing in these locations allows Eaton to offer competitive pricing, particularly in the rapidly growing Asian market. The strategic distribution of these facilities across China helps Eaton efficiently meet regional demand and ensures a consistent supply of high-quality hydraulic fittings.

Whether your Eaton hydraulic fitting comes from the U.S. or one of these Chinese facilities, you can trust that it meets the same exacting standards. The choice often depends on personal preference, cost considerations, or specific application needs.

II. Who Are Eaton’s Suppliers?

Eaton’s ability to produce high-quality hydraulic fittings is partly due to its strong relationships with a global network of suppliers. These suppliers provide the raw materials and components needed to manufacture Eaton’s products, including metals like steel and aluminum, as well as specialized rubber and synthetic materials used in seals and hoses.

Eaton carefully selects its suppliers based on several criteria, such as quality, reliability, and sustainability. Suppliers must meet Eaton’s strict standards, which include compliance with environmental regulations and ethical business practices. This rigorous selection process ensures that every part used in Eaton’s hydraulic fittings meets the high standards the company is known for.

By sourcing materials from trusted suppliers across the world, Eaton can maintain a consistent supply chain, ensuring that their hydraulic fittings are always of top-notch quality.

III. Are Eaton Hydraulic Fittings Made in the Same Factories as Taske’s Products?

Eaton and Taske may both operate in the manufacturing sector, but they serve different roles, and their production processes are generally separate. Taske is a well-known manufacturer that specializes in producing various industrial components, including those used in hydraulic systems, but it does not operate as a standalone brand for hydraulic fittings like Eaton.

Eaton produces its hydraulic fittings in dedicated factories strategically located across the globe, including various cities in China mentioned earlier. These facilities are part of Eaton’s extensive manufacturing network and use advanced technology to produce a wide range of hydraulic components. By keeping production in-house, Eaton can maintain strict quality control and consistency across its product lines.

Taske typically manufactures components for hydraulic systems under contract or in partnership with other companies. This means that while Taske may produce components for Eaton or other brands, Eaton manufactures its hydraulic fittings in its own certified facilities.

This separation ensures that Eaton produces its products according to exacting standards, giving customers confidence in the reliability and quality of Eaton hydraulic fittings.

IV. Is Eaton a Good Brand for Hydraulic Fittings?

When it comes to hydraulic fittings, Eaton is a name that frequently comes up—and for good reason. Eaton has built a solid reputation for quality, innovation, and reliability over the years, making it a trusted brand in the industry.

One of the reasons Eaton stands out is its commitment to research and development. The company continually invests in new technologies and processes to improve the performance and durability of its products. Eaton focuses on innovation, ensuring that its hydraulic fittings meet the evolving needs of industries that rely on hydraulic systems.

Quality control is another area where Eaton excels. Every hydraulic fitting undergoes rigorous testing before it reaches the market. This includes pressure testing, material analysis, and endurance testing to ensure the fittings can handle tough conditions without failure.

Customers and industry professionals alike often praise Eaton for the reliability of its hydraulic fittings. The company’s dedication to quality has earned it a loyal customer base, making Eaton a go-to brand for many when it comes to hydraulic systems.

Frequently Searched Questions About Eaton:

- What does Eaton Corporation do?

Eaton is a diversified power management company with a broad product portfolio that includes electrical components, hydraulic systems, aerospace components, vehicle components, filtration systems, and lighting solutions. The company serves a wide range of industries, from industrial manufacturing to aerospace and automotive. - Is Eaton a Fortune 500 company?

Yes, Eaton is a Fortune 500 company. It consistently ranks among the largest corporations in the United States by revenue, reflecting its significant global footprint and diverse product offerings. - Where is Eaton Corporation headquartered?

Eaton’s global headquarters are located in Dublin, Ireland. The company moved its headquarters to Ireland in 2012 after merging with Cooper Industries. Eaton maintains a significant presence in Cleveland, Ohio, where it headquarters its North American operations. - How do Eaton and Cooper Industries relate?

Eaton acquired Cooper Industries in 2012, which significantly expanded Eaton’s product offerings, particularly in the electrical sector. The merger also influenced the relocation of Eaton’s corporate headquarters to Dublin, Ireland. - Does Eaton make products for the aerospace industry?

Yes, Eaton manufactures a variety of products for the aerospace industry, including hydraulic, fuel, and pneumatic systems and components. These products support both commercial and military aerospace applications.

V. Where Are Eaton’s Headquarters Located?

Eaton Corporation’s global headquarters are located in Dublin, Ireland. This may surprise some, especially those who associate Eaton with its American roots. The company moved its headquarters to Dublin in 2012 after merging with Cooper Industries, which was based in Ireland. The move was strategic, allowing Eaton to benefit from Ireland’s favorable business environment while still maintaining its global operations.

However, Eaton also has a significant presence in the United States, where it has been a key player since its founding. The North American headquarters are in Cleveland, Ohio, a city that remains central to Eaton’s operations. From this location, Eaton manages many of its key business functions, ensuring smooth operation across its global network.

With a strong base in both Ireland and the U.S., Eaton is poised to continue leading in the power management and hydraulic systems industries.

VI. Who Are Eaton’s Competitors?

Eaton isn’t the only big name in the hydraulic fittings game. The company faces stiff competition from several other brands that also have a strong foothold in the market. Here are some of Eaton’s main competitors:

- Parker Hannifin: A close rival, Parker Hannifin is a global leader in motion and control technologies. Like Eaton, Parker offers a wide range of hydraulic fittings known for their quality and reliability.

- Swagelok: Swagelok is a prominent manufacturer of fluid system components, including fittings, valves, hoses, and regulators. Known for precision and high-quality standards, Swagelok is a strong competitor to Eaton, particularly in sectors requiring highly reliable and leak-tight fittings.

- Stauff: Stauff specializes in hydraulic components, including fittings, clamps, and filters. They serve a global market and are a direct competitor to Eaton, especially in the area of hydraulic fittings.

- Gates Corporation: Gates is another heavyweight in the hydraulic industry. The company earns high regard for its innovation and customer service, offering a variety of hoses, fittings, and related products.

- Danfoss: Danfoss is a global leader in hydraulic and electronic control systems, with a strong presence in mobile hydraulics. The company’s products are often seen as alternatives to Eaton’s offerings.

These competitors help keep the hydraulic fittings market dynamic and innovative, pushing each other—and Eaton—to continuously improve and deliver better products.

VII. What Are the Products of Eaton?

Eaton is much more than just hydraulic fittings. The company’s product portfolio is vast, catering to a wide range of industries and applications. Here’s a look at some of Eaton’s key product categories:

- Hydraulic Components: Eaton’s range includes hoses, fittings, pumps, motors, valves, and cylinders used in hydraulic systems. These products are vital in industries like agriculture, construction, and manufacturing.

- Electrical Products: Eaton also produces electrical components, systems, and services for power distribution, control, and automation. This includes everything from circuit breakers to uninterruptible power supplies (UPS).

- Aerospace Components: Eaton supplies hydraulic, fuel, and pneumatic systems and components to the aerospace industry, supporting both commercial and military applications.

- Vehicle Components: Eaton manufactures transmission systems, clutches, and superchargers for the automotive sector. Heavy-duty trucks and buses widely use these products.

- Filtration Systems: Eaton offers filtration solutions for industrial and commercial applications, including hydraulic, fuel, and water filtration products.

- Lighting Solutions: Eaton designs its lighting products for energy efficiency, and they are used in commercial, industrial, and residential settings.

Eaton’s wide array of products demonstrates the company’s versatility and ability to meet the diverse needs of its customers across various industries. Whether you’re looking for hydraulic fittings or sophisticated electrical systems, Eaton has something to offer.