Hydraulic systems are everywhere in manufacturing, even if you don’t notice them at first glance. These systems operate on the principles of fluid mechanics, using pressurized liquid to create force and motion. Sounds simple, right? But their impact on manufacturing processes is massive—offering unmatched power, efficiency, and precision.

In this blog, we’ll explore how hydraulic systems work, their benefits, key applications in manufacturing, and some of the latest innovations driving the industry forward.

What Are Hydraulic Systems and How Do They Work?

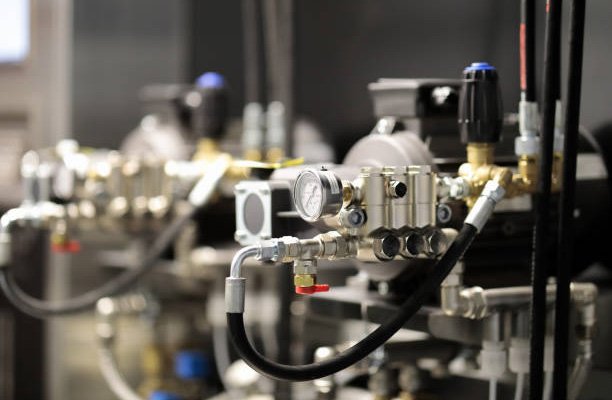

At its core, a hydraulic system uses incompressible fluid (like oil or water) to transmit power. When fluid is pressurized within a closed system, it generates mechanical force and motion. Hydraulic systems typically consist of:

- Hydraulic Pumps: To pressurize the fluid.

- Valves: To control fluid flow.

- Cylinders or Motors: To convert pressure into mechanical work.

The beauty of these systems is their ability to amplify force. For example, even a small hydraulic pump can lift or move tons of weight—making it indispensable in industrial settings.

Why Are Hydraulic Systems Important in Manufacturing?

Hydraulic systems bring a range of advantages that make them essential for manufacturing operations. Here’s why:

- High Power-to-Weight Ratio

Hydraulic systems can generate a lot of power with compact components, making them ideal for tight spaces or heavy workloads. - Precision and Control

With the right valves and feedback mechanisms, hydraulic systems offer pinpoint accuracy in movements—essential for tasks like robotic assembly or molding. - Durability and Reliability

Built to handle extreme pressures and harsh conditions, these systems are incredibly robust and reliable, requiring minimal downtime. - Cost Efficiency

While the initial setup can be costly, the long-term operational costs of hydraulic systems are often lower due to their energy efficiency and low maintenance needs.

Key Applications of Hydraulic Systems in the Manufacturing Industry

Hydraulic systems touch nearly every corner of the manufacturing industry. Here are some key applications:

1. Material Handling

Hydraulic-powered forklifts, conveyors, and cranes are essential for moving raw materials, components, and finished goods across manufacturing facilities.

2. Machinery and Tooling

Hydraulics drive heavy equipment like presses, injection molding machines, and cutting tools. For instance:

- Press Brakes: Use hydraulics to bend and shape metal sheets with precision.

- Injection Molding Machines: Use hydraulic pressure to create plastic components for industries like automotive or electronics.

3. Automation and Robotics

In the age of smart factories, hydraulic systems are key to automating repetitive tasks, like assembling car parts or packaging products.

4. Testing and Quality Control

Hydraulic test stands are used to simulate real-world conditions, ensuring manufactured parts can withstand stress and pressure.

5. Metalworking and Foundries

From casting to forging, hydraulic systems power the tools that shape metal into parts and components for industries like aerospace, automotive, and construction.

Innovations in Hydraulic Systems for Manufacturing

As technology evolves, so do hydraulic systems. Here are some exciting innovations shaping the future:

1. Electro-Hydraulic Systems

Combining hydraulics with electronics, these systems allow for smarter control and monitoring. Think of it as adding a brain to the muscle—making them more precise, efficient, and adaptive.

2. Energy-Efficient Hydraulics

Manufacturers are focusing on reducing energy consumption. Systems now use variable-speed pumps and advanced control algorithms to cut waste while maintaining performance.

3. Compact and Lightweight Designs

New materials and designs are making hydraulic systems smaller and lighter without sacrificing power, making them more versatile for modern factories.

4. Integration with IoT (Internet of Things)

Hydraulic systems are becoming part of the larger Industry 4.0 ecosystem. Sensors and IoT connectivity allow for real-time monitoring, predictive maintenance, and improved performance tracking.

Challenges in Using Hydraulic Systems

Despite their advantages, hydraulic systems come with challenges. Here’s what manufacturers need to watch out for:

- Leakage Issues: Hydraulic fluid leaks can cause efficiency losses and environmental concerns.

- Maintenance: Regular maintenance is required to keep the system running smoothly.

- Initial Cost: High upfront investment for equipment and installation can be a barrier for small manufacturers.

Luckily, advancements in design and technology are helping to overcome these challenges, making hydraulics even more attractive.

Hydraulic Systems vs. Pneumatic Systems: Which One’s Better?

A common question in manufacturing is whether to use hydraulic or pneumatic systems. While both have their place, here’s a quick comparison:

| Aspect | Hydraulic Systems | Pneumatic Systems |

|---|---|---|

| Medium Used | Liquid (oil or water) | Compressed air |

| Force Output | High | Moderate |

| Precision | High | Moderate |

| Cost | Higher upfront cost | Lower upfront cost |

| Applications | Heavy-duty machinery | Lightweight, repetitive tasks |

Hydraulic systems are ideal for high-power applications, while pneumatic systems are better suited for tasks requiring less force and more speed.

Hydraulic systems are the unsung heroes of the manufacturing industry, providing the power, precision, and reliability needed to keep operations running smoothly. From material handling to robotic automation, their applications are vast and continually evolving with technology.

Conclusion

As manufacturing embraces Industry 4.0, innovations like IoT integration and energy-efficient designs will make hydraulic systems even more indispensable. Whether you’re running a small factory or a large-scale operation, investing in modern hydraulic solutions is a surefire way to boost efficiency and stay competitive.