Introduction

When working with plumbing, gas, or hydraulic systems, understanding thread types is crucial for ensuring proper sealing and compatibility. One of the most commonly used thread standards worldwide is the British Standard Pipe (BSP) thread. However, many people wonder: Is BSP tapered or parallel? The answer is that BSP threads come in two variations—BSPT (British Standard Pipe Tapered) and BSPP (British Standard Pipe Parallel).

This article will explore the differences between these thread types, their applications, and how to identify the right one for your needs.

What is BSP (British Standard Pipe)?

British Standard Pipe (BSP) is a widely used thread standard for pipes and fittings in plumbing and industrial applications. It was originally developed in the 19th century to create a standardized method for connecting pipes in the UK and has since been adopted globally.

BSP threads are defined by the ISO 228 (for parallel threads) and ISO 7 (for tapered threads) standards. These threads are commonly used in water, gas, and hydraulic systems due to their reliable sealing properties.

Key Features of BSP Threads:

- BSP threads use a 55-degree thread angle, different from the 60-degree angle of NPT (National Pipe Thread).

- They are measured in inches, with common sizes including 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, and larger.

- BSP threads are commonly found in Europe, Asia, and Australia but are less common in North America.

Types of BSP Threads

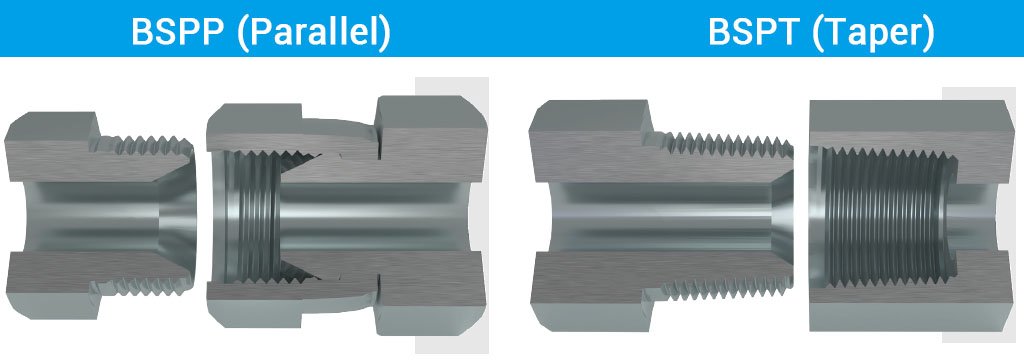

BSP threads are categorized into two main types:

1. BSPT (British Standard Pipe Tapered)

- These threads have a tapered profile, meaning the diameter gradually decreases along the length of the thread.

- They create a metal-to-metal seal by wedging into the mating component.

- Often used in high-pressure applications such as gas fittings, hydraulics, and compressed air systems.

2. BSPP (British Standard Pipe Parallel)

- These threads have a constant diameter along their length.

- They require a sealing washer or O-ring to ensure a leak-proof connection.

- Commonly used in low-pressure applications, such as plumbing, water systems, and general industrial use.

Understanding these differences is essential when selecting fittings for your specific application. In the next sections, we’ll dive deeper into the characteristics, applications, and sealing methods for BSPT and BSPP threads.

BSPT (Tapered) Threads

What Are BSPT Threads?

BSPT (British Standard Pipe Tapered) threads are designed with a taper, meaning their diameter gradually decreases from one end to the other. This tapering allows the threads to create a mechanical seal when tightened, forming a leak-resistant connection.

Key Features of BSPT Threads:

- Tapered thread profile (threads get smaller toward the end).

- Self-sealing—as the threads tighten, they create a tight, leak-proof connection.

- Requires thread sealant (PTFE tape or pipe dope) for extra security.

- Commonly used in high-pressure systems such as gas, steam, and hydraulic applications.

Where Are BSPT Threads Used?

BSPT threads are ideal for systems that transport fluids or gases under pressure, including:

- Hydraulic and pneumatic systems

- Gas pipelines and fittings

- High-pressure water and steam connections

- Industrial machinery

Because BSPT threads create a tight seal, they are preferred for applications where leaks could be hazardous or cause system failures.

BSPP (Parallel) Threads

What Are BSPP Threads?

BSPP (British Standard Pipe Parallel) threads maintain a consistent diameter throughout their length. Unlike BSPT, BSPP threads do not form a mechanical seal on their own. Instead, they rely on an additional sealing washer or O-ring to prevent leaks.

Key Features of BSPP Threads:

- Constant thread diameter (no tapering).

- Requires a gasket, washer, or O-ring for sealing.

- Ideal for low-pressure applications where a secure mechanical seal is unnecessary.

- Used in plumbing, fluid transfer, and general industrial connections.

Where Are BSPP Threads Used?

Since BSPP threads don’t provide a self-sealing connection, they are best suited for low-pressure applications, such as:

- Water supply and plumbing systems

- Fuel and oil transfer lines

- Irrigation and agricultural equipment

- Industrial cooling systems

BSPP connections are commonly found in non-critical applications where ease of assembly and disassembly is important.

Key Differences Between BSPT and BSPP

Now that we’ve explored BSPT and BSPP threads, let’s break down their main differences:

| Feature | BSPT (Tapered) | BSPP (Parallel) |

|---|---|---|

| Thread Shape | Tapered (gradual diameter reduction) | Parallel (constant diameter) |

| Sealing Method | Metal-to-metal seal | Requires a washer or O-ring |

| Thread Standard | ISO 7 / EN 10226 | ISO 228 |

| Pressure Handling | High-pressure applications | Low-pressure applications |

| Common Uses | Gas, hydraulics, steam, air systems | Water, fuel, cooling systems |

| Leak Prevention | Requires PTFE tape or sealant | Seals with a washer |

How to Choose the Right BSP Thread:

- Use BSPT if you need a self-sealing connection in high-pressure applications.

- Use BSPP if you require a washer or O-ring for a reliable seal in low-pressure systems.

Understanding these differences ensures you select the correct fitting and avoid costly leaks or mismatches.

Identifying BSP Threads: How to Tell the Difference

If you’re working with BSP fittings, it’s essential to identify whether you have BSPT or BSPP threads to ensure compatibility. Here are some methods to determine the difference:

1. Visual Inspection

- BSPT threads have a noticeable taper, meaning the thread diameter decreases along the length.

- BSPP threads maintain a consistent diameter from end to end.

2. Measuring the Thread

Use a caliper to measure the thread diameter at different points:

- If the diameter changes, it’s a BSPT thread.

- If the diameter remains constant, it’s a BSPP thread.

3. Using a Thread Gauge

A thread gauge is the most accurate way to determine the thread type:

- Tapered Thread Gauge: If the BSP thread matches a tapered gauge, it is BSPT.

- Parallel Thread Gauge: If the thread aligns perfectly with a parallel gauge, it is BSPP.

4. Checking the Connection Type

- BSPT threads seal by wedging into the fitting.

- BSPP threads require a sealing washer or O-ring to prevent leaks.

By following these identification techniques, you can quickly determine the correct BSP thread type for your application.

BSP vs. Other Thread Standards (NPT, ISO, Metric)

While BSP threads are common, they are not the only pipe thread standard. It’s crucial to understand how they compare to other types.

BSP vs. NPT (National Pipe Thread)

| Feature | BSP (BSPT/BSPP) | NPT (National Pipe Thread) |

|---|---|---|

| Thread Angle | 55° | 60° |

| Tapered Threads | BSPT only | NPT is always tapered |

| Sealing Method | BSPT: Metal-to-metal, BSPP: Washer/O-ring | Requires PTFE tape or sealant |

| Usage | Europe, Asia, Australia | USA, Canada |

Key Takeaway: BSP and NPT threads are NOT interchangeable due to different thread angles and sealing mechanisms.

BSP vs. ISO Metric Threads

- ISO metric threads are commonly used in machine components.

- BSP threads have a 55° thread angle, while metric threads use a 60° angle.

- Metric threads are measured in millimeters, whereas BSP threads use inch-based sizing.

BSP vs. G and R Threads

- G Threads: These are parallel BSPP threads defined by ISO 228.

- R Threads: These are tapered BSPT threads following ISO 7.

Understanding these differences prevents costly mistakes and ensures compatibility in international projects.

Common Applications of BSP Threads

BSP threads are widely used across industries due to their reliability and versatility. Below are some common applications:

BSPT (Tapered) Thread Applications

- High-pressure hydraulic systems

- Gas and steam pipelines

- Compressed air systems

- Oil and fuel transfer lines

- Heavy machinery and industrial equipment

BSPP (Parallel) Thread Applications

- Water supply systems and plumbing

- Fuel and lubrication lines

- HVAC and cooling systems

- Agricultural irrigation

- Low-pressure pneumatic systems

BSP threads are preferred in industries where leak prevention, durability, and compatibility are critical.

Can BSPT and BSPP Be Interchanged?

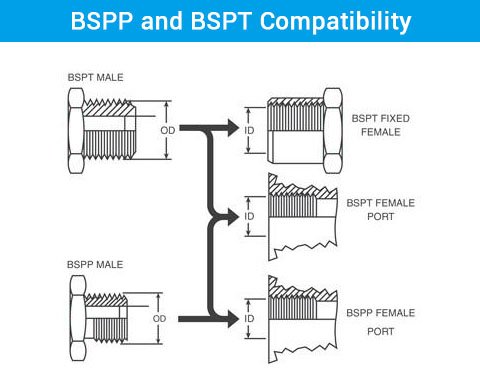

One of the most common questions regarding BSP threads is whether BSPT (tapered) and BSPP (parallel) can be used together. The short answer is: it depends on the application and sealing method.

When Can BSPT and BSPP Be Used Together?

- If a BSPT male (tapered) thread is inserted into a BSPP female (parallel) fitting, it might create a seal, but only if thread sealant (like PTFE tape) is used.

- Some manufacturers design BSPP female fittings with a slight taper, allowing BSPT male threads to fit securely.

When Should BSPT and BSPP NOT Be Used Together?

- A BSPP male (parallel) thread cannot seal in a BSPT female (tapered) fitting because there is no matching taper for sealing.

- In high-pressure applications, mixing BSPT and BSPP can lead to leakage or failure if not properly sealed.

Best Practices:

- Always use matching thread types whenever possible.

- If mixing BSPT and BSPP, apply PTFE tape or thread sealant to prevent leaks.

- Use a sealing washer or O-ring for BSPP connections.

Sealing Methods for BSP Threads

Proper sealing is essential to prevent leaks in BSP connections. The sealing method depends on whether you’re using BSPT or BSPP threads.

Sealing BSPT (Tapered) Threads

- How It Seals: BSPT threads create a metal-to-metal seal as they are tightened.

- Best Practices:

- Use PTFE tape (Teflon tape) or pipe dope to improve sealing.

- Ensure a tight fit but avoid over-tightening to prevent damage.

Sealing BSPP (Parallel) Threads

- How It Seals: BSPP threads require a washer, O-ring, or gasket to prevent leaks.

- Best Practices:

- Always use a rubber or metal washer for sealing.

- Make sure the mating surface is clean and smooth to avoid leaks.

- If the fitting has an O-ring, check that it is properly seated and undamaged.

Choosing the Right Sealing Method

| Thread Type | Sealing Method |

|---|---|

| BSPT (Tapered) | PTFE tape, pipe dope |

| BSPP (Parallel) | Washer, O-ring, or gasket |

Selecting the right sealing technique ensures a leak-proof connection and extends the lifespan of your fittings.

How to Choose the Right BSP Thread for Your Application

When selecting a BSP thread type, consider the following factors:

1. Pressure Requirements

- Use BSPT (tapered) for high-pressure applications such as gas, steam, and hydraulic systems.

- Use BSPP (parallel) for low-pressure systems like water lines and fuel transfer.

2. Sealing Method

- BSPT forms a self-sealing connection but requires PTFE tape.

- BSPP requires an O-ring or washer for a leak-free seal.

3. Industry and Application

- BSPT is best for: Gas pipelines, steam systems, compressed air lines, hydraulic systems.

- BSPP is ideal for: Water supply systems, plumbing, HVAC, and fluid transfer.

4. Compatibility with Other Standards

- Ensure BSP fittings match the correct ISO standard (ISO 7 for BSPT, ISO 228 for BSPP).

- Check if your system requires NPT or metric threads instead of BSP.

By considering these factors, you can select the right BSP thread type for a safe, secure, and efficient connection.

BSP Thread Standards and Regulations

BSP threads follow strict international standards to ensure compatibility and reliability across different industries. The two main standards governing BSP threads are:

1. ISO 7 – Pipe Threads for Pressure-Tight Joints

- Covers BSPT (tapered) threads.

- Defines specifications for sealing without the use of a washer.

- Used in high-pressure applications such as gas, steam, and hydraulic systems.

2. ISO 228 – Pipe Threads Where Pressure-Tight Joints Are Not Made on the Threads

- Covers BSPP (parallel) threads.

- Requires the use of a sealing washer or O-ring to ensure a leak-proof connection.

- Commonly used in water systems, fuel lines, and fluid transfer applications.

Other Relevant Standards

- EN 10226: European standard equivalent to ISO 7.

- BS 21: The British Standard for BSP pipe threads.

- DIN 3852: German standard for BSP threads in hydraulic applications.

Understanding these standards ensures compliance with industry regulations and guarantees safe and leak-proof installations.

Conclusion

Understanding the difference between BSPT (tapered) and BSPP (parallel) threads is crucial for selecting the right fittings in plumbing, gas, hydraulic, and fluid transfer systems.

FAQsestions about BSP threads:

1. Are BSP and NPT threads interchangeable?

No, BSP and NPT threads are not compatible due to differences in thread angle (55° vs. 60°) and sealing methods.

2. Can BSPT be used with BSPP?

Only in certain cases—BSPT male can fit into BSPP female with sealant, but BSPP male cannot seal properly in a BSPT female fitting.

3. Do BSP threads need PTFE tape?

- BSPT (tapered) threads require PTFE tape or pipe sealant.

- BSPP (parallel) threads need a washer or O-ring for sealing.

4. How can I tell if a thread is BSPT or BSPP?

- BSPT (tapered) threads get narrower along their length.

- BSPP (parallel) threads maintain a consistent diameter.

5. What is the most common BSP thread size?

The most common sizes are 1/4″, 3/8″, 1/2″, 3/4″, and 1″ BSP, used in plumbing and industrial applications.