In the intricate world of hydraulic systems, where fluid pressure translates into mechanical power, hydraulic fittings play a foundational role. These components are often overlooked, yet they are crucial to ensuring the integrity, efficiency, and safety of fluid power systems. This article provides a comprehensive deep dive into their functions, importance, types, and maintenance.

Understanding Hydraulic Systems

To truly grasp the function of a hydraulic fitting, one must first understand the broader framework in which it operates — the hydraulic system.

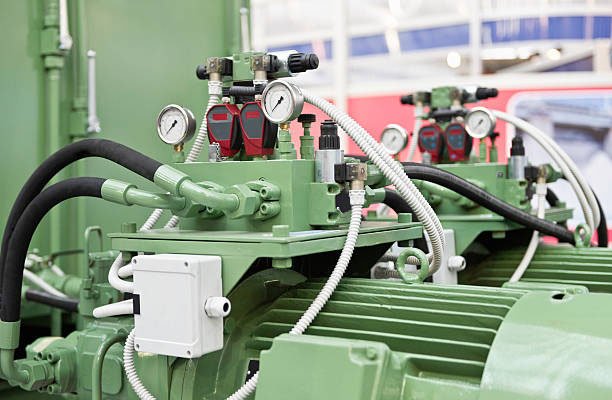

A hydraulic system uses fluid, typically oil, to transmit energy from one location to another. It operates based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This allows small amounts of input force to generate large output force, making hydraulic systems ideal for heavy-duty applications like earth-moving equipment, aircraft control systems, and manufacturing machinery.

Key Elements of a Hydraulic System

- Hydraulic Fluid – Serves as the medium for power transmission.

- Pump – Converts mechanical energy into hydraulic energy.

- Actuators – Cylinders or motors that convert fluid energy back into mechanical energy.

- Valves – Control fluid flow and direction.

- Reservoir – Stores the hydraulic fluid.

- Fittings, Hoses, and Pipes – Connect various components and facilitate fluid movement.

Every component must work seamlessly together to maintain pressure, direction, and efficiency. Hydraulic fittings are the bridges between these components, creating a sealed path for fluid to travel without leaks or pressure loss.

What is a Hydraulic Fitting?

At its core, a hydraulic fitting is a mechanical connector used to join sections of pipe, tube, or hose within a hydraulic system. These connectors are designed to withstand extreme internal pressures while maintaining a tight, leak-free seal.

But hydraulic fittings do more than just connect—they ensure the safe, continuous operation of complex machinery. By maintaining integrity under pressure, they help systems operate reliably even in harsh environments.

Characteristics of Hydraulic Fittings

- Pressure Resistance: Capable of handling pressures up to thousands of PSI.

- Temperature Tolerance: Built to withstand extreme heat or cold, depending on the application.

- Corrosion Resistance: Materials often chosen to resist wear and chemical damage.

- Precision Engineering: Designed to fit exactly within the tolerances of the system, preventing misalignment or leaks.

Hydraulic fittings come in an array of shapes, sizes, and threading styles to fit various types of tubing and hoses. The correct fitting ensures that energy transfers efficiently and safely through the system.

Types of Hydraulic Fittings

Hydraulic fittings are not a one-size-fits-all solution. They come in different styles based on system requirements, pressure ranges, and installation environments.

1. Compression Fittings

Used for low to moderate pressure systems, these fittings compress a ferrule against the pipe or tube as the nut is tightened, creating a secure seal.

2. Crimped Fittings

Commonly found in high-pressure environments, crimped fittings are permanently attached to a hose using a crimping tool. They provide high reliability and strength.

3. Threaded Fittings

Threaded fittings screw into place, often using pipe dope or Teflon tape to enhance sealing. They are used where removable connections are required.

4. Flare Fittings

Flare fittings involve flaring the tube end to create a conical seal. They are excellent for high-pressure applications and provide metal-to-metal sealing.

5. Reusable Fittings

These are designed to be installed and removed multiple times without damage. Often used in applications where frequent maintenance or modifications are necessary.

Materials Used in Hydraulic Fittings

The choice of material in a hydraulic fitting is critical, not only for ensuring mechanical performance but also for achieving chemical compatibility and environmental resistance. Selecting the right material helps avoid corrosion, degradation, and premature failure, especially in demanding operating conditions.

1. Stainless Steel

Stainless steel is widely used in high-pressure and corrosive environments such as marine applications, offshore drilling rigs, and chemical processing plants. It offers:

- Exceptional corrosion resistance

- High strength

- Durability in extreme temperatures

However, stainless steel fittings are generally more expensive than alternatives.

2. Carbon Steel

Carbon steel fittings are the most common in general industrial applications. They offer:

- Good strength and durability

- Lower cost than stainless steel

- Coatings available for added corrosion resistance (e.g., zinc plating)

These are often used in agriculture, construction, and hydraulic lifts.

3. Brass

Brass is suitable for lower-pressure applications and systems that require corrosion resistance without the high strength of steel. It is:

- Easy to machine and install

- Resistant to corrosion from water and certain chemicals

- Ideal for plumbing and refrigeration

4. Plastic or Polymer

Plastic fittings are typically used in low-pressure systems or environments requiring chemical inertness. Common in food processing and certain medical devices, their benefits include:

- Lightweight construction

- Cost-effectiveness

- Resistance to many chemicals

Each material has its pros and cons, and the final choice depends on pressure rating, operating temperature, fluid compatibility, and budget.

Top Functions of Hydraulic Fittings

Hydraulic fittings do much more than merely “connect things together.” They are precision-engineered components essential for system integrity and performance. Let’s dive into their core functions:

1. Secure Mechanical Connections

They create strong, mechanical connections between hoses, tubes, and components, holding them together under pressure and vibration.

2. Seal Fluid Pathways

Fittings help maintain a sealed hydraulic circuit, preventing leakage which could lead to inefficiency, equipment damage, or environmental hazards.

3. Direct Fluid Flow

With different shapes like elbows, tees, and crosses, fittings help in routing hydraulic fluid in the desired direction through complex circuits.

4. Maintain System Pressure

They are designed to withstand specific PSI ratings without failure. A well-installed fitting ensures that pressure is maintained throughout the circuit.

5. Facilitate Maintenance

Some fittings are made for quick disconnection, allowing operators to maintain or upgrade components without disrupting the whole system.

6. Enable System Flexibility

Hydraulic systems often need to adapt to spatial or functional changes. Fittings provide that flexibility by allowing redirection, branching, or even connecting different sizes of tubing.

Connecting Components Securely

One of the fundamental roles of hydraulic fittings is to securely connect various parts of a hydraulic system—pipes, hoses, valves, pumps, and actuators—ensuring they function as a unified, leak-proof mechanism.

Threaded Connections

In many cases, threaded fittings are used to connect components securely. These come in different thread types like NPT (National Pipe Thread), BSP (British Standard Pipe), or metric threads. Proper sealing compounds are usually applied to avoid leaks.

Hose End Fittings

Hose fittings come in multiple configurations like straight, 45-degree, or 90-degree bends. These connections are often reinforced with ferrules and crimped for added strength.

Ferrule and Nut Systems

In systems using metal tubes, ferrules (metal rings) are compressed against the tube by tightening a nut. This forms a tight, high-pressure seal that prevents leaks and withstands vibrations.

Key Security Factors

- Proper torque application ensures that the fitting is neither too loose (causing leaks) nor too tight (causing thread damage).

- Alignment checks during assembly prevent misfitting and unnecessary stress on the joints.

- Locking mechanisms like O-rings or clamps are often employed for added security in high-vibration systems.

A securely connected fitting keeps the system running efficiently and prevents costly failures due to disconnection or leakage.

Supporting System Maintenance

Hydraulic systems require regular maintenance to ensure safety, performance, and longevity. Hydraulic fittings play an essential role in this process by enabling easy disconnection, replacement, or reconfiguration of components—minimizing downtime and simplifying service procedures.

Why Maintenance Matters

- Prevents Failures: Identifies and replaces worn or damaged parts before they cause breakdowns.

- Ensures Safety: Avoids hazardous leaks or burst lines due to degraded fittings.

- Extends Equipment Life: Keeps systems running at optimal performance over time.

Fittings That Aid Maintenance

- Quick-Connect Fittings: Allow for fast, tool-free disconnection and reconnection, often used in mobile and emergency applications.

- Swivel Fittings: Reduce torsional stress, enabling smoother maintenance of rotating or moving parts.

- Reusable Fittings: Can be detached and reinstalled multiple times, reducing the need for spares.

Maintenance-Friendly Features

- Clearly labeled connections for faster identification

- Color-coded seals or collars for compatibility checks

- Built-in test ports to measure system pressure and performance

Efficient system maintenance is possible only when fittings are accessible, reliable, and designed for reuse or quick replacement. Selecting such fittings enhances both uptime and worker safety.

Hydraulic Fittings and Safety

Safety is paramount in any hydraulic system, especially those operating under high pressure and in challenging environments. A faulty or poorly selected hydraulic fitting can lead to catastrophic results, from equipment damage to serious injury. This makes the safety function of fittings absolutely critical.

Safety Risks from Faulty Fittings

- High-Pressure Leaks: Can cause fluid injection injuries or fires if the fluid is flammable.

- Fitting Blowouts: May result from exceeding pressure ratings or improper installation.

- Environmental Hazards: Fluid spills can harm ecosystems or violate safety regulations.

Built-in Safety Mechanisms

- Burst Protection: Many fittings are engineered with burst ratings well above working pressure.

- Pressure Relief Components: Integrated valves or escape ports prevent overpressure conditions.

- Double-Sealing Systems: Reduce the risk of failure by adding redundant sealing points.

Compliance and Standards

Fittings should comply with standards from organizations like:

- SAE (Society of Automotive Engineers)

- ISO (International Organization for Standardization)

- DIN (Deutsches Institut für Normung)

Always ensure fittings are certified and tested for the specific application to meet both workplace safety and regulatory compliance.

Common Applications of Hydraulic Fittings

Hydraulic fittings are essential across a wide variety of industries, each demanding specific performance characteristics. Their ability to connect, seal, and direct fluid makes them indispensable in both high-precision and high-power applications.

1. Construction Equipment

- Used in backhoes, bulldozers, cranes, and excavators.

- Require high-pressure fittings with extreme vibration resistance.

2. Agriculture

- Found in tractors, plows, and harvesters.

- Must endure dirt, dust, and temperature fluctuations while maintaining performance.

3. Automotive and Transportation

- Critical in power steering systems, braking systems, and hydraulic lifts.

- Require compact, corrosion-resistant fittings for tight spaces.

4. Aviation and Aerospace

- Used in aircraft landing gear, flight control systems, and cargo handling.

- Require ultra-lightweight, temperature-resistant, and highly secure fittings.

5. Manufacturing and Automation

- Power presses, robotic arms, and CNC machinery rely on hydraulic motion.

- Fittings must support both high precision and quick maintenance.

6. Marine and Offshore

- Found in winches, anchor systems, and hydraulic deck machinery.

- Need fittings with excellent corrosion resistance due to saltwater exposure.

Industrial Use Cases

Hydraulic fittings are crucial in industrial settings, where they must perform reliably under continuous use, high pressure, and extreme environmental conditions. Here are some of the most common industrial applications and how hydraulic fittings play a role in each:

1. Manufacturing Plants

Hydraulic systems power a variety of automated equipment in manufacturing, such as stamping machines, injection molding systems, and robotic arms. Fittings in these settings:

- Enable compact, high-pressure connections

- Support rapid tool changeover with quick-disconnects

- Must withstand constant vibration and pressure cycling

2. Oil and Gas Industry

In drilling rigs, hydraulic fittings are used in systems like blowout preventers, pipe handling equipment, and mud pumps. They:

- Operate under high pressure and in corrosive environments

- Require stainless steel or specially coated carbon steel

- Must meet strict international safety standards

3. Steel and Metal Processing

Hydraulic presses, roll-forming equipment, and furnace lifts depend on precise pressure control:

- Fittings must tolerate extreme heat and heavy loading

- Reusable and crimped fittings are common due to the need for strength and reliability

4. Waste Management and Recycling

Hydraulic cylinders power compactors, balers, and shredders. Here:

- Fittings must handle debris exposure, chemicals, and moisture

- Easy maintenance access is essential due to high mechanical stress

5. Energy and Utilities

Used in dam gates, wind turbines, and hydroelectric plants:

- Require fittings capable of handling variable load cycles

- Long-lasting seals to minimize maintenance

These examples emphasize how hydraulic fittings are tailored to meet the unique challenges of different industrial environments.

Signs of a Faulty Hydraulic Fitting

A faulty hydraulic fitting can lead to dangerous failures and expensive downtime. Recognizing early warning signs allows technicians to replace or repair parts before major issues arise.

1. Visible Leaks

The most obvious sign, fluid leakage indicates that the fitting is no longer sealing properly. This could be due to:

- Worn O-rings or seals

- Loose connections

- Cracks in the fitting body

2. Pressure Drops

If your system is not operating at full pressure, a compromised fitting could be the culprit. Symptoms include:

- Sluggish actuator movement

- Intermittent power output

- Inconsistent system performance

3. Unusual Noises

Hissing, whining, or banging sounds can indicate air intrusion through leaking fittings or pressure surges from improper flow.

4. Fluid Contamination

Cracks or poor sealing can allow contaminants to enter the hydraulic fluid, which may damage pumps, valves, and actuators.

5. Excessive Heat

A loose or blocked fitting can restrict flow, causing the system to overheat.

6. Visible Damage

Rust, deformation, or thread wear can compromise the fitting’s integrity.

Routine inspection and proactive replacement of damaged fittings are key to avoiding unplanned outages or hazardous failures.

Selecting the Right Hydraulic Fitting

Choosing the appropriate hydraulic fitting is not just about matching sizes—it’s a strategic decision that affects system performance, safety, and cost.

1. Pressure Rating

Always choose fittings rated above the system’s maximum operating pressure. Never assume compatibility based on appearance.

2. Thread Type

Different thread types (NPT, BSP, JIC, metric) are not always interchangeable. Mismatched threads can cause leaks or breakage.

3. Size and Flow Capacity

Oversized fittings may be bulky and expensive; undersized ones can restrict fluid flow, reducing system efficiency.

4. Material Compatibility

Match the fitting material with the fluid and environment:

- Stainless steel for corrosive environments

- Brass for low-pressure systems

- Carbon steel for general industrial use

5. Seal Type

Choose between O-rings, compression seals, or metal-to-metal flare designs based on pressure, temperature, and application.

6. Environmental Conditions

Consider temperature fluctuations, vibration, UV exposure, or the presence of corrosive chemicals when choosing a fitting.

7. Ease of Maintenance

In systems requiring frequent servicing, opt for quick-disconnect or reusable fittings to save time and labor.

Proper fitting selection ensures that your hydraulic system is safe, efficient, and easy to maintain—maximizing return on investment.

Proper Installation Techniques

Even the most high-quality hydraulic fittings can fail if they are not installed correctly. Proper installation ensures long-term reliability, leak-free performance, and system safety. Here’s how to do it right:

1. Preparation is Key

Before installation, make sure all components are:

- Clean and free from dirt, dust, and metal shavings

- Free from burrs or deformities on threads or flared surfaces

- Compatible in terms of size, thread type, and pressure rating

2. Use Correct Tools

Using the wrong tool can damage fittings and compromise sealing. Common tools include:

- Torque wrenches to apply manufacturer-specified torque

- Flare tools for accurate tube flaring

- Crimping machines for hose fittings

3. Apply Proper Torque

Over-tightening can strip threads or deform seals; under-tightening can lead to leaks. Always:

- Use a torque chart or follow the manufacturer’s instructions

- Tighten in stages if necessary

- Use a marker to visually confirm final tightening

4. Thread Sealants and Tapes

For tapered-thread fittings (e.g., NPT), use:

- PTFE (Teflon) tape or pipe dope rated for hydraulic use

- Avoid over-applying sealant, which can contaminate the system

Note: Never use sealants on fittings with built-in O-rings or face seals.

5. Pressure Test After Installation

Once installed, always run a pressure test to:

- Detect potential leaks

- Validate system pressure integrity

- Ensure no components are under stress or misaligned

By following these best practices, you can avoid costly errors and ensure your system functions safely from the start.

Maintenance Tips for Longevity

Hydraulic fittings endure extreme conditions. Regular inspection and maintenance can significantly extend their lifespan and reduce system downtime. Here’s how to keep them in top shape:

1. Perform Visual Inspections

- Look for signs of wear, corrosion, or leaks

- Check for loose fittings or cracked hoses

- Inspect O-rings and seals for brittleness or damage

2. Clean System Components

- Keep fittings and surrounding areas clean from dust, oil, and debris

- Flush the hydraulic system periodically to remove contaminants

3. Lubricate When Required

- Some fittings benefit from light lubrication (especially reusable types)

- Use only manufacturer-approved lubricants to avoid seal degradation

4. Replace Damaged Fittings Immediately

Never attempt to “patch” or reuse a damaged fitting under pressure. Always replace with a part that matches system specs exactly.

5. Store Fittings Correctly

- Store in a cool, dry place to avoid oxidation or contamination

- Keep different materials separated to prevent galvanic corrosion

6. Keep Maintenance Records

Track installation dates, inspections, and replacements to anticipate wear and plan proactive replacements.

Regular and careful maintenance enhances reliability, reduces risk, and ensures the hydraulic system delivers optimal performance throughout its lifecycle.

Conclusion

Hydraulic fittings are far more than simple connectors. They are meticulously engineered components that play a vital role in ensuring the efficiency, safety, and longevity of hydraulic systems. From maintaining high-pressure seals and preventing leaks to enabling directional flow and simplifying maintenance, their functions are diverse yet fundamentally interconnected.

Understanding what is the function of a hydraulic fitting empowers engineers, technicians, and system designers to make informed choices about selection, installation, and care. Whether operating in construction machinery, industrial manufacturing, or aerospace technology, the right hydraulic fitting can make the difference between optimal performance and costly failure.

Here are the key takeaways:

- Precision Matters: Choose fittings that match your system’s pressure rating, fluid compatibility, and environmental demands.

- Maintenance is Non-Negotiable: Regular inspections, proper cleaning, and timely replacements extend the life of your system.

- Safety First: Always prioritize fittings that meet or exceed industry standards for performance and reliability.

FAQs

Here are six of the most common questions people ask about hydraulic fittings:

Q1. Can I reuse hydraulic fittings?

A: Some types, like reusable or quick-connect fittings, are designed for multiple installations. However, always inspect them for thread wear, corrosion, or seal damage before reuse.

Q2. What causes a hydraulic fitting to leak?

A: Leaks can result from improper installation, damaged O-rings, incorrect torque, or using incompatible thread types. Frequent vibrations and pressure surges can also loosen fittings over time.

Q3. How do I know which thread type I have?

A: Use a thread identification kit or caliper and pitch gauge to measure threads. Reference charts are available to match measurements with standard thread types like NPT, BSP, or JIC.

Q4. What’s the difference between crimped and reusable fittings?

A: Crimped fittings are permanently attached using a crimping machine and offer a secure, high-pressure seal. Reusable fittings can be manually installed and removed, ideal for systems needing frequent service.

Q5. Do I need sealant on every fitting?

A: No. Only tapered thread fittings typically require PTFE tape or sealant. Face-seal or O-ring fittings should not use additional sealants, as they can compromise sealing surfaces.

Q6. How often should I inspect my hydraulic fittings?

A: For high-use systems, visual inspections should occur weekly, with a full inspection every 3–6 months. In critical systems, follow manufacturer or industry-specific guidelines.