Introduction to Hydraulic Quick Couplers

Which Quick Coupler Fits Your Needs? That’s a crucial question for anyone working with hydraulic systems—the lifeline of industries such as construction, agriculture, mining, and manufacturing. These powerful systems rely on pressurized fluids to transfer energy, and while the machinery may be large and complex, one small component often determines how efficiently everything runs: the hydraulic quick coupler.

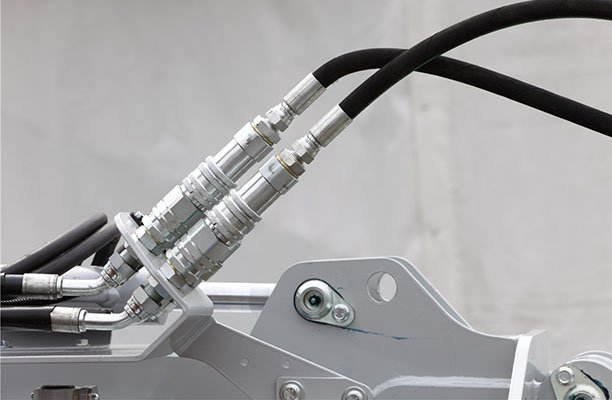

Think of a quick coupler as the handshake between hydraulic hoses and machines. Without it, connecting and disconnecting hoses would be time-consuming, messy, and potentially hazardous. Choosing the right coupler ensures your system operates at peak performance while minimizing downtime, leaks, and costly repairs.

This guide walks you through the different types of couplers, their key applications, expert tips for selection, and maintenance best practices to extend their lifespan. Whether you’re running heavy-duty excavators or farming tractors, the right coupler can make or break your hydraulic system’s reliability.

What Are Hydraulic Quick Couplers?

Hydraulic quick couplers—also known as quick disconnect couplings—are mechanical devices that allow you to connect and disconnect hydraulic lines rapidly without tools. They are designed to:

- Provide a secure, leak-free seal between hydraulic hoses and units.

- Handle high-pressure fluids without losing efficiency.

- Reduce downtime when equipment needs frequent attachment changes.

- Prevent contamination, which is one of the biggest enemies of hydraulic systems.

Most couplers consist of a male part (the plug) and a female part (the socket). When connected, internal locking mechanisms and seals ensure a tight fit, even under extreme pressure. When disconnected, many designs include valves that automatically close, preventing oil from spilling.

Their widespread use across industries stems from one core benefit: efficiency without compromising safety.

Why Quick Couplers Are Essential for Hydraulic Units

Hydraulic units often need to switch between different tools or attachments—excavators switching from a bucket to a breaker, tractors moving from a sprayer to a plow, or robots shifting from one assembly tool to another. Without quick couplers, operators would need to manually detach hoses, risking fluid exposure, air intrusion, and system contamination.

The benefits of quick couplers include:

- Leak Prevention – Modern couplers feature flat-face or self-sealing designs that prevent fluid loss.

- Contamination Control – By sealing tightly, they stop dust, dirt, or water from entering hydraulic systems.

- Safety Enhancement – They reduce the chances of fluid injection injuries and minimize operator exposure to hot, pressurized oil.

- Time Savings – Switching attachments becomes a quick, tool-free process, reducing downtime and improving productivity.

- System Protection – By ensuring pressure consistency, they help prevent costly system failures.

In short, hydraulic quick couplers are not just a convenience—they are a necessity for anyone who values safety, reliability, and performance in fluid power systems.

Types of Hydraulic Quick Couplers

Hydraulic quick couplers are not one-size-fits-all. Each type is engineered with specific strengths and applications in mind. Choosing the wrong type can lead to leaks, reduced efficiency, and even equipment failure. Below are the four most common types of hydraulic couplers you’ll encounter, along with their advantages and limitations.

Flat Face Hydraulic Quick Couplers

Flat face couplers are one of the most advanced and widely used designs in modern hydraulic systems. They are built with a flat sealing surface that minimizes fluid spillage when connecting or disconnecting.

Advantages:

- Virtually leak-free connection and disconnection.

- Easy to clean—just wipe the flat surface before connecting.

- Excellent for environments where contamination control is critical.

- Designed to handle high pressures and heavy-duty applications.

Best For: Construction, agriculture, forestry, and industries where hydraulic attachments are frequently changed.

Ball-Type Quick Couplers

Ball-type couplers are among the oldest and most commonly used designs. They rely on spring-loaded steel balls to lock the male and female halves together.

Advantages:

- Cost-effective and widely available.

- Simple design with proven durability.

- Ideal for general-purpose use across multiple industries.

Limitations:

- More prone to leakage compared to flat face couplers.

- Can allow dirt and debris into the hydraulic system if not cleaned properly.

Best For: General agricultural and construction equipment that doesn’t require strict contamination control.

Threaded Hydraulic Couplers

Threaded couplers use screw-on connections to ensure an exceptionally strong and secure fit. Unlike ball-type couplers, they resist accidental disconnection and are suitable for extreme pressure environments.

Advantages:

- Can withstand very high operating pressures.

- Resistant to vibrations and mechanical shocks.

- Less likely to disconnect accidentally under load.

Limitations:

- Slower to connect and disconnect than other designs.

- Requires more effort to ensure proper tightening.

Best For: Oil and gas equipment, mining machinery, and heavy-duty industrial use.

Wing Nut Couplers

Wing nut couplers feature large hand-tightened threads, making them easy to attach and remove without tools. They are designed for the toughest hydraulic applications where other couplers may fail.

Advantages:

- Excellent for extremely high-pressure hydraulic systems.

- Can be tightened or loosened by hand, even with gloves.

- Very durable and reliable in rugged environments.

Limitations:

- Bulkier than other coupler designs.

- Slower to connect compared to flat face couplers.

Best For: Oil rigs, drilling applications, and mining where durability and safety are critical.

Key Factors to Consider When Choosing a Quick Coupler

When selecting a hydraulic quick coupler, it’s important not to simply pick the cheapest or most common option. Instead, consider how your equipment will be used and what challenges your hydraulic system faces. Here are the key factors to evaluate:

Pressure Rating and Compatibility

Always ensure the coupler’s pressure rating matches—or exceeds—your system’s working pressure. Using a coupler below your equipment’s PSI rating can result in leaks, damage, or dangerous blowouts.

Flow Capacity and Efficiency

Couplers with small internal passages can restrict flow, reducing machine performance. Select a coupler with the right bore size to maintain proper flow rates.

Durability and Material Selection

- Steel: Strong and affordable, suitable for most applications.

- Stainless Steel: Corrosion-resistant, ideal for marine and chemical environments.

- Brass/Composite: Lightweight, but not suited for heavy-duty use.

Environmental Conditions and Safety Standards

- For dusty or muddy environments → Flat face couplers are best.

- For high-vibration machinery → Threaded couplers prevent accidental disconnection.

- For industries with strict safety standards → Look for ISO 16028 flat face couplers or other certified designs.

Applications of Hydraulic Quick Couplers

Hydraulic quick couplers aren’t limited to one field—they are found in almost every industry that uses pressurized fluid systems. Let’s look at where they are most commonly applied.

Construction and Heavy Equipment

Excavators, loaders, bulldozers, and skid steers frequently switch between attachments like buckets, breakers, and augers. Quick couplers reduce downtime by allowing operators to switch tools in minutes rather than hours.

Agriculture and Farming Machinery

Tractors and harvesters rely heavily on hydraulic implements such as plows, sprayers, and balers. Farmers benefit from couplers that withstand dirt and mud while maintaining a strong, leak-free seal.

Industrial Manufacturing and Robotics

In manufacturing plants, quick couplers are used on robotic arms and assembly lines, enabling fast tool changes without shutting down production. Flat face couplers are especially popular here to minimize contamination.

Oil, Gas, and Mining Operations

These industries operate under some of the harshest conditions imaginable—high pressure, extreme vibration, and abrasive environments. Threaded and wing nut couplers dominate here due to their strength and safety features.

Common Mistakes to Avoid When Selecting a Coupler

Even experienced operators and technicians can make costly mistakes when selecting hydraulic quick couplers. These errors often lead to leaks, equipment failure, or dangerous working conditions. Here are the most common pitfalls to avoid:

1. Ignoring Pressure and Temperature Limits

Every coupler is designed to handle a specific pressure (PSI) and temperature range. Installing one that doesn’t match your hydraulic unit can cause blowouts, damaged seals, or even operator injuries.

Tip: Always check your system’s specifications and ensure the coupler exceeds the maximum working pressure.

2. Choosing the Wrong Material

Not all couplers are created equal. Using a steel coupler in a corrosive environment or a brass coupler in a heavy-duty machine will dramatically shorten its lifespan.

- Steel: Great for general construction and agriculture.

- Stainless steel: Best for marine, food, and chemical industries.

- Brass: Suitable for low-pressure or non-critical applications.

3. Overlooking Safety Features

Some operators focus only on flow rate and cost, overlooking features like safety locks, valve shut-offs, or anti-blowout designs. These features may seem minor, but in practice, they can prevent leaks, injuries, and costly downtime.

Rule of Thumb: Always prioritize safety-certified couplers that meet ISO or SAE standards for hydraulic systems.

Expert Tips for Selecting the Right Hydraulic Quick Coupler

Now that we’ve covered mistakes, let’s focus on what experts recommend when choosing couplers. These insights will help ensure you get the best performance from your hydraulic units.

1. Match the Coupler to Your Equipment Needs

Always start with your equipment manufacturer’s recommendations. The OEM often specifies which couplers work best with their hydraulic attachments. This prevents mismatched fittings and performance losses.

2. Consider Ease of Maintenance and Replacement

Couplers inevitably wear out over time, but some designs are easier to maintain than others. Flat face couplers, for example, have fewer parts exposed to dirt and are easier to clean, while threaded couplers require more effort.

Tip: Choose a coupler that your maintenance team can replace quickly to minimize downtime.

3. Opt for Leak-Free, High-Performance Designs

Even a small leak can lead to hydraulic fluid loss, pressure drops, and contamination risks. Modern flat face couplers are designed to be nearly leak-free and are often the best investment for equipment that changes attachments frequently.

Expert Insight: Spending a little more on premium couplers can save thousands in reduced downtime and repair costs.

How to Maintain and Extend the Life of Quick Couplers

Buying the right coupler is only half the battle—maintenance plays a major role in extending their lifespan. Without proper care, seals wear out faster, contaminants invade your system, and connections weaken over time.

1. Regular Cleaning and Inspection

- Wipe coupler faces before every connection to prevent dirt from entering the system.

- Inspect for scratches, cracks, or worn-out seals.

- Replace damaged O-rings immediately to prevent leaks.

2. Lubrication and Seal Replacement

Hydraulic couplers contain moving parts that benefit from light lubrication. Apply a suitable grease sparingly to locking balls or threads to prevent wear.

- Replace seals annually or sooner if you notice fluid seepage.

- Always use manufacturer-approved seals for compatibility.

3. Preventing Contamination in Hydraulic Systems

Contamination is the silent killer of hydraulic equipment. One grain of dirt can scratch valves, clog filters, and wear out pumps.

Best Practices:

- Use dust caps when couplers are not connected.

- Store spare couplers in clean, sealed containers.

- Flush new hoses and couplers before installation.

With these steps, a well-maintained coupler can last several years—even in demanding environments.

Benefits of Using the Right Hydraulic Quick Coupler

Selecting the correct hydraulic quick coupler is more than a matter of convenience—it directly impacts safety, efficiency, and long-term costs. Here are the key benefits you’ll experience with the right choice:

1. Improved Safety and Performance

A properly matched coupler ensures a tight, leak-free connection, reducing the risk of hydraulic fluid spray, high-pressure blowouts, or operator injury. Modern designs, like flat face couplers, also minimize fluid exposure during disconnection, keeping workplaces cleaner and safer.

2. Reduced Downtime and Maintenance Costs

Time is money—especially on construction sites, farms, or factory floors. Quick couplers drastically reduce the time spent switching attachments, meaning equipment stays operational longer. Additionally, well-designed couplers prevent leaks and contamination, which lowers repair and maintenance expenses.

3. Enhanced Equipment Longevity

Contaminants and pressure drops caused by poor couplers are among the leading causes of premature hydraulic system failure. By using the right coupler, you protect pumps, hoses, and valves, ultimately extending the life of your entire hydraulic system.

Conclusion

Hydraulic quick couplers may be small, but they play a huge role in system efficiency, safety, and durability. From construction machinery to farming equipment and industrial robotics, the right coupler ensures smooth operation, prevents costly leaks, and extends equipment life.

When choosing a coupler, always consider:

- Pressure ratings to match your hydraulic unit

- Material durability for your environment

- Contamination control to protect your system

- Ease of maintenance for long-term performance

FAQs

1. What size quick coupler do I need for my hydraulic system?

The size depends on your hose diameter and flow requirements. Always match the coupler bore size to your hydraulic line to avoid flow restrictions.

2. Can I mix and match different coupler types?

No. Each coupler type has a unique locking and sealing mechanism. Mixing them will lead to leaks and system inefficiencies. Always pair male and female parts of the same type and size.

3. How do I know if my coupler is leaking?

Common signs include:

- Visible oil seepage around the connection

- Pressure drops in the hydraulic system

- Unusual noises (hissing or whistling) during operation

4. Are flat face couplers better than ball type?

It depends on your application:

- Flat face couplers → Best for high-pressure, contamination-sensitive industries.

- Ball type couplers → More affordable and effective for general-purpose use.

5. How often should I replace hydraulic couplers?

With proper maintenance, couplers can last several years. However, heavy-use industries should inspect couplers regularly and replace them every 12–24 months or sooner if wear is evident.

6. Do hydraulic quick couplers work with all types of fluids?

Most couplers are designed for hydraulic oil, but some are compatible with synthetic or water-based fluids. Always check manufacturer specifications for fluid compatibility.