Quick connect fittings are designed to make plumbing, automotive, and industrial connections easy, but when they fail, it can cause serious problems—ranging from minor leaks to complete system breakdowns. If you’ve found your quick connect fitting not working, don’t worry. This article will walk you through everything you need to know: from how they function, to the most common causes of failure, and finally to detailed troubleshooting steps to get your system running again.

Introduction to Quick Connect Fittings

Quick connect fittings are widely used in homes, vehicles, and industries because they allow for fast, tool-free connections. Instead of threading, soldering, or gluing, a quick connect fitting uses an internal mechanism to grip the tubing and seal the connection. This makes them a go-to choice for:

- Home plumbing systems (water filtration, ice makers, under-sink connections)

- Automotive applications (fuel lines, transmission systems, hydraulic hoses)

- Compressed air tools (air hoses, pneumatic systems)

- Irrigation systems (drip irrigation, sprinkler lines)

The primary benefit is convenience—but when they don’t work correctly, it’s usually due to an underlying issue that can be fixed with the right approach.

How Quick Connect Fittings Work

Basic Mechanism Explained

A quick connect fitting is designed to lock and seal tubing with minimal effort. It has two main components:

- Collet (Gripping Teeth): A small ring with metal or plastic teeth that grip the tubing when it’s pushed in.

- O-Ring Seal: A rubber gasket inside the fitting that forms a watertight or airtight seal around the tubing.

When you insert tubing into the fitting, the collet grabs onto the pipe while the O-ring seals around it. To disconnect, you simply press the collet inward and pull the tubing out.

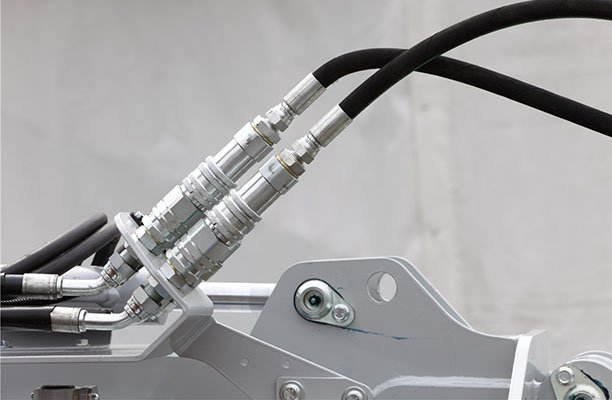

Common Applications in Plumbing, Air, and Hydraulics

- Plumbing: Ideal for PEX, copper, or plastic tubing. You’ll see them in DIY water filter systems, ice makers, and irrigation setups.

- Automotive & Hydraulics: Used in high-pressure fuel lines, transmission systems, and hydraulic applications where reliability and speed are essential.

- Compressed Air Systems: Found in garages and workshops, they make switching air tools quick and easy without wrenches or sealants.

These fittings are designed for convenience, but their efficiency depends heavily on proper installation, correct sizing, and system maintenance.

Common Reasons for Quick Connect Fitting Not Working

If you notice a quick connect fitting not working, it usually comes down to one of these problems:

Incorrect Installation

- Tubing not pushed in all the way.

- Wrong tubing size used.

- Uneven or jagged cut on the tubing that prevents a tight seal.

Damaged O-Rings or Seals

- O-rings can dry out, crack, or wear down over time.

- Lubricant (like silicone grease) may be needed during installation to prevent tearing.

Dirt, Debris, or Mineral Build-Up

- Hard water leaves calcium and mineral deposits.

- Dust or small particles block the O-ring from sealing properly.

- Especially common in irrigation and plumbing systems.

Worn-Out or Cracked Fittings

- Plastic fittings can become brittle with age or UV exposure.

- Metal fittings may corrode or crack under extreme pressure.

Pressure or Temperature Issues

- Exceeding the manufacturer’s rated PSI or temperature range can cause leaks or sudden disconnection.

- Freezing conditions can damage fittings and cause leaks when thawed.

Step-by-Step Troubleshooting Guide

If your quick connect fitting isn’t working properly, the best approach is to break down the problem systematically. Follow this guide to identify and fix the issue:

1: Inspect the Connection Point

- Remove the tubing and examine both the fitting and the tubing ends.

- Look for cracks, scratches, or deformation on the tubing—this can prevent a proper seal.

- Check that the tubing is cut perfectly square. A slanted or jagged cut often leads to leaks.

Tip: Use a dedicated pipe cutter instead of a hacksaw to ensure smooth, even cuts.

2: Check O-Rings and Seals

- Carefully inspect the O-ring inside the fitting.

- If it looks dry, cracked, or misshapen, replace it.

- Lightly lubricating with silicone grease can help prolong O-ring life and improve sealing.

3: Clean and Remove Blockages

- Hard water deposits, dirt, and debris are common culprits.

- Flush both the tubing and fitting with clean water or compressed air.

- If buildup is visible, soak the fitting in a vinegar solution to dissolve mineral deposits.

4: Test Pressure and Flow

- Reconnect and turn on the system gradually.

- Check for leaks under both low and high pressure.

- Ensure the system isn’t exceeding the manufacturer’s PSI rating.

5: Replace Damaged Fittings

- If cracks, corrosion, or permanent damage are found, replacement is the only solution.

- Always use a fitting rated for your specific application (water, air, fuel, or hydraulics).

Preventing Quick Connect Fitting Failures

Once fixed, the next step is prevention. Regular care and correct usage can significantly extend the life of quick connect fittings.

Regular Inspection and Maintenance

- Inspect fittings every few months for leaks or wear.

- In high-use systems (like air compressors), check weekly.

- Replace O-rings proactively before they fail.

Using the Right Fittings for the Job

- Not all quick connect fittings are universal.

- For example, a plumbing fitting may not handle the pressure in a hydraulic system.

- Always match the material (plastic, brass, stainless steel) to your system’s needs.

Proper Cleaning Techniques

- Periodically flush water lines to prevent mineral buildup.

- Use inline filters in fuel and water systems to reduce debris.

- Store air tools and hoses properly to keep dust out of fittings.

Best Practices for Installing Quick Connect Fittings

Many problems start during installation. By following best practices, you can avoid leaks and ensure long-lasting performance.

Measuring Correct Tubing Size

- Always confirm tubing diameter matches the fitting specification.

- Even a small mismatch (e.g., 1/4″ vs. 6mm) can result in leaks.

Ensuring a Leak-Free Seal

- Push the tubing all the way until it seats firmly past the O-ring.

- Tug lightly to confirm the collet is gripping correctly.

Avoiding Over-Tightening

- While quick connect fittings don’t usually require tools, some have threaded connections.

- Over-tightening can crack plastic fittings or strip threads on metal ones.

- Hand-tight plus a quarter turn is usually sufficient.

When to Replace vs. Repair

Quick connect fittings are affordable, but depending on the application, you might wonder whether repairing is a viable option. Here’s how to decide:

Cost Considerations

- Low-cost fittings (like those used in home plumbing) are usually cheaper to replace than repair. A single fitting can cost just a few dollars.

- Industrial or specialty fittings (like stainless steel hydraulic connectors) may be expensive, so replacing only the damaged O-ring or seal can save money.

Safety Concerns

- In fuel, brake, or hydraulic systems, safety should always come first.

- Even if a fitting looks like it can be repaired, it’s better to replace it entirely to avoid catastrophic failure under pressure.

- For water and air systems, a minor repair may be acceptable if it passes pressure testing.

Signs You Should Replace Instead of Repairing

- Visible cracks or warping in the fitting body.

- Repeated leaks despite replacing O-rings.

- Fittings exposed to extreme heat, cold, or UV damage.

Industry Examples of Quick Connect Fitting Issues

Quick connect fittings are used across multiple industries, and each has its unique challenges.

Plumbing Systems

- Common Issue: Leaks near sinks, dishwashers, or water filters.

- Cause: Mineral buildup or worn O-rings.

- Solution: Replace O-rings, clean fittings, or swap out with a new connector.

Automotive and Hydraulic Systems

- Common Issue: Fuel or hydraulic fluid leaks, sometimes accompanied by performance loss.

- Cause: High vibration, heat, and pressure wear out fittings faster.

- Solution: Always replace damaged fittings—repairing isn’t worth the risk in safety-critical systems.

Air Compressor Systems

- Common Issue: Hissing sounds, air loss, and pressure drops.

- Cause: Dust, dirt, or worn collet teeth that don’t grip tubing properly.

- Solution: Clean and lubricate fittings regularly. Replace worn-out connectors to maintain full PSI.

Conclusion

If your quick connect fitting isn’t working, the problem is usually simple—damaged O-rings, dirt buildup, or improper installation. Most issues can be solved by inspecting the seals, cleaning the fitting, and making sure the tubing is inserted correctly. When fittings are cracked or keep failing, replacement is the safest and most cost-effective solution.

With proper installation and routine checks, quick connect fittings can deliver years of reliable, leak-free service.

FAQs

Q1. Why is my quick connect fitting leaking even after I tightened it?

Because quick connects rely on an O-ring seal, tightening won’t help. The issue is usually a damaged O-ring, improper tubing insertion, or debris blocking the seal.

Q2. Can I reuse a quick connect fitting after disconnecting it?

Yes, most fittings are reusable. However, repeated connections and disconnections may wear out the O-ring faster. Always inspect before reuse.

Q3. Do I need plumber’s tape with a quick connect fitting?

No. Quick connect fittings are designed to seal without tape. Using tape can actually interfere with the sealing mechanism.

Q4. What’s the lifespan of a quick connect fitting?

In normal conditions, fittings can last 5–10 years. But in high-pressure, high-vibration, or outdoor environments, replacement may be needed sooner.

Q5. How do I stop my air compressor fitting from popping off?

Ensure the tubing is fully inserted, check for collet wear, and confirm you’re using the correct size. Replacing the fitting is often the fastest fix.

Q6. Can extreme temperatures affect quick connect fittings?

Yes. Freezing can crack plastic fittings, while excessive heat can dry out O-rings and cause leaks. Always use fittings rated for your climate.