Why Hydraulic Hose Quality Matters More Than You Think

Understanding How to Tell If a Hydraulic Hose Is High Quality? is essential because hydraulic hoses are among the most critical safety components in any hydraulic system. They are responsible for transporting pressurized fluid that powers heavy machinery, industrial equipment, and mobile systems. A single hose failure can lead to serious injuries, environmental damage, and expensive downtime.

High-quality hydraulic hoses are designed to withstand extreme pressure, constant vibration, temperature fluctuations, and chemical exposure. They maintain system efficiency by minimizing fluid loss, pressure drop, and energy waste. In contrast, low-quality hoses often degrade silently, showing little warning before sudden failure.

Many hydraulic accidents occur not because of incorrect system design, but because hoses were selected based on price rather than performance. A reliable hose protects both equipment and personnel while ensuring long-term operational stability.

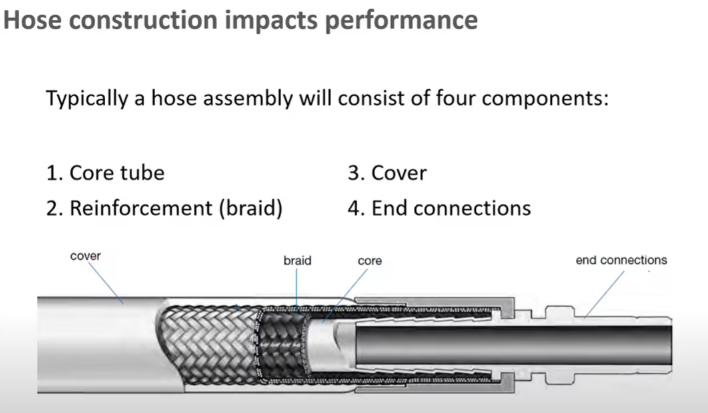

Basic Structure of a Hydraulic Hose and Why Each Layer Matters

One of the most effective ways to evaluate How to Tell If a Hydraulic Hose Is High Quality? is to understand its internal construction. A hydraulic hose is a multi-layered assembly, with each layer performing a specific and essential function.

The inner tube is the core of the hose and directly contacts the hydraulic fluid. High-quality hoses use advanced synthetic rubber or PTFE materials that resist oil, chemicals, and temperature extremes. A poorly designed inner tube may swell, crack, or leach material into the fluid, which can damage valves, pumps, and seals throughout the system.

Surrounding the inner tube is the reinforcement layer. This layer provides the hose with its pressure-carrying strength. Premium hoses use high-tensile steel wire braid or spiral-wound wire reinforcement that is evenly spaced and firmly bonded. This prevents excessive expansion, deformation, and sudden rupture under pressure.

The outer cover is the hose’s protective shield. It guards against abrasion, oil exposure, UV radiation, ozone, and harsh environmental conditions. High-quality outer covers remain flexible while resisting cuts, cracking, and wear. A thin or brittle outer layer is often an early sign of inferior manufacturing.

Material Quality as a Key Indicator of Hose Performance

Material selection plays a defining role in determining How to Tell If a Hydraulic Hose Is High Quality?. Each material used in hose construction must be carefully chosen to match the application’s pressure, fluid type, and environment.

High-quality inner tubes are formulated to resist chemical breakdown and maintain flexibility over time. They perform reliably with mineral oils, synthetic fluids, and biodegradable hydraulic oils without swelling or hardening. Inferior materials may initially function but degrade rapidly under continuous exposure.

Reinforcement materials are equally important. High-grade steel wire reinforcement provides superior fatigue resistance, allowing the hose to withstand millions of pressure cycles. Lower-quality hoses may use weaker wire or inconsistent reinforcement patterns, increasing the risk of internal failure.

The outer cover material determines how well the hose survives external abuse. Premium covers are abrasion-resistant and oil-resistant, ensuring longer service life even in demanding industrial or mobile environments. Material shortcuts in this layer often lead to early cracking and exposure of reinforcement wires.

Pressure Ratings, Burst Strength, and Safety Margins

One of the most reliable ways to judge How to Tell If a Hydraulic Hose Is High Quality? is by closely examining its pressure ratings and safety margins. Hydraulic systems rarely operate under steady pressure. Instead, they experience constant fluctuations, spikes, and shock loads. A high-quality hydraulic hose is engineered with this reality in mind.

Every premium hose clearly specifies its maximum working pressure, which is the highest pressure it can safely handle during continuous operation. More importantly, it also specifies a burst pressure, which represents the pressure level at which the hose will fail. In high-quality hydraulic hoses, the burst pressure is typically at least four times higher than the working pressure. This built-in safety factor protects the system from sudden pressure surges caused by rapid valve closure, load changes, or emergency stops.

Low-quality hoses often lack consistent pressure testing. Some may advertise high pressure ratings but fail to maintain those ratings across repeated impulse cycles. Over time, internal reinforcement weakens, leading to unpredictable failures. A high-quality hose maintains pressure integrity across millions of pressure pulses, ensuring long-term reliability and operator safety.

Another subtle but important indicator is volumetric expansion. Inferior hoses expand noticeably under pressure, absorbing energy and reducing system efficiency. High-quality hoses are designed to limit expansion, resulting in faster response times, smoother operation, and improved overall system control.

Flexibility, Bend Radius, and Resistance to Fatigue

Flexibility is often misunderstood when evaluating How to Tell If a Hydraulic Hose Is High Quality?. A good hose is not simply soft or rigid—it strikes a precise balance between flexibility and structural strength.

High-quality hydraulic hoses specify a minimum bend radius, which defines how tightly the hose can bend without damaging internal layers. When installed within this limit, the hose maintains full flow capacity and reinforcement stability. Inferior hoses may kink, flatten, or collapse when bent, restricting fluid flow and increasing internal stress.

Fatigue resistance is especially important in applications where hoses move constantly, such as excavators, loaders, presses, and robotic systems. Each pressure cycle and movement places stress on the reinforcement wires. Premium hoses use high-tensile wire and advanced bonding techniques to prevent wire breakage and layer separation over time.

A simple physical evaluation often reveals quality differences. High-quality hoses bend smoothly and return to shape without cracking sounds or stiffness. Low-quality hoses may feel uneven, overly stiff, or weak near fittings, signaling poor reinforcement or inadequate material bonding.

Temperature Range and Hydraulic Fluid Compatibility

Temperature and fluid compatibility are critical factors in determining How to Tell If a Hydraulic Hose Is High Quality?, yet they are frequently overlooked. Hydraulic systems operate across a wide range of temperatures, from freezing outdoor environments to high-heat industrial conditions.

High-quality hoses are engineered to remain flexible in cold temperatures while retaining strength and pressure capacity at elevated temperatures. They do not harden, blister, or soften excessively when exposed to heat. Inferior hoses often become brittle in cold conditions or degrade rapidly when exposed to sustained heat, dramatically shortening their service life.

Fluid compatibility is equally important. Hydraulic systems may use mineral oils, synthetic oils, water-based fluids, or biodegradable hydraulic fluids. A premium hose is formulated to resist chemical reactions with these fluids, preventing swelling, softening, or internal cracking. Poor-quality hoses may absorb fluid, leading to internal degradation and contamination of the hydraulic system.

Always verify that the hose’s inner tube material matches the specific hydraulic fluid and temperature range of the application. A mismatch, even with a well-constructed hose, can result in early failure and system damage.

Hose Markings, Labeling Accuracy, and Traceability

A clear and often overlooked indicator of How to Tell If a Hydraulic Hose Is High Quality? is the information printed directly on the hose. High-quality hydraulic hoses are permanently marked with precise, legible, and standardized information that allows users to verify suitability and trace origin.

A premium hose typically includes:

- Manufacturer’s name or trademark

- Hose size and inside diameter

- Maximum working pressure

- Applicable industry standards (such as SAE, ISO, or EN)

- Temperature range

- Date code or batch number

These markings are not decorative—they confirm that the hose has been produced under controlled manufacturing processes. The print should be evenly spaced, durable, and resistant to oil, abrasion, and weathering. If markings fade easily or appear inconsistent, it often suggests poor-quality outer cover materials or substandard production controls.

Traceability is especially important in industrial and safety-critical applications. High-quality manufacturers can trace a hose back to its production batch, raw materials, and testing records. This level of accountability is a strong signal that the hose meets strict quality and safety expectations.

Inspection Methods That Reveal Hidden Quality Issues

Knowing How to Tell If a Hydraulic Hose Is High Quality? also involves understanding how to inspect a hose beyond surface appearance. While visual inspection is important, deeper evaluation reveals long-term reliability.

Start with a close surface inspection. A high-quality hose has a smooth, uniform outer cover without blisters, cracks, flat spots, or exposed reinforcement. Any visible wire braid or spiral is a warning sign that the hose is already compromised.

Next, evaluate dimensional consistency. Premium hoses maintain a consistent diameter along their entire length. Variations may indicate uneven reinforcement or improper curing during manufacturing.

Flex testing can also expose quality differences. Gently bend the hose within its recommended radius. A high-quality hose bends smoothly and evenly, while inferior hoses may show stiffness, uneven resistance, or surface cracking sounds.

Finally, inspect the hose ends. Quality hoses maintain strong adhesion between layers near fittings. Poor-quality hoses often fail first at the coupling area due to weak bonding or inconsistent reinforcement placement.

Supplier Credibility, Technical Support, and Documentation

Another critical factor in determining How to Tell If a Hydraulic Hose Is High Quality? is the reliability of the supplier. High-quality hoses are rarely sold without comprehensive technical documentation and professional support.

Reputable suppliers provide detailed datasheets outlining pressure ratings, temperature limits, fluid compatibility, bend radius, and applicable standards. These documents help ensure proper hose selection and reduce the risk of misapplication.

Strong suppliers also offer technical assistance for hose selection, installation guidance, and troubleshooting. This support reflects confidence in product quality and long-term performance. In contrast, sellers of low-quality hoses often provide minimal documentation and limited accountability.

Warranty policies are another indicator. High-quality hose manufacturers stand behind their products with clear warranties and defined service expectations. While no hose lasts forever, a manufacturer willing to support its product demonstrates trust in its materials, processes, and testing.

Evaluating supplier credibility alongside hose construction provides a more complete and reliable picture of overall quality.

Proper Installation Practices That Preserve Hose Quality

Even the best hose can fail prematurely if it is installed incorrectly, which is why installation plays a key role in understanding How to Tell If a Hydraulic Hose Is High Quality? over time. A truly high-quality hose maintains its performance characteristics when installed according to manufacturer guidelines.

Correct routing is essential. High-quality hoses are designed to follow smooth, natural curves rather than sharp bends. Twisting a hose during installation places internal stress on the reinforcement layers, reducing fatigue life. Premium hoses resist twisting better than low-quality ones, but no hose is immune to improper handling.

Adequate clearance from sharp edges, hot surfaces, and moving components further protects hose integrity. High-quality hoses often tolerate harsh environments better, yet proper clamping and protective sleeves significantly extend service life. Attention to these details ensures the hose’s quality is fully utilized rather than compromised.

Correct fitting selection and crimping are equally important. High-quality hoses are manufactured to tight dimensional tolerances, ensuring proper sealing when paired with compatible fittings. Inferior hoses may not crimp evenly, increasing the risk of leaks or blow-off under pressure.

Common Causes of Premature Hydraulic Hose Failure

Understanding failure modes helps clarify How to Tell If a Hydraulic Hose Is High Quality? by revealing how well a hose resists real-world stresses. Premature failures are often linked to poor material quality or inadequate design.

One common cause is excessive pressure beyond rated limits. High-quality hoses tolerate brief pressure spikes due to robust reinforcement, while low-quality hoses may rupture suddenly. Another frequent issue is abrasion. Premium outer covers resist wear far longer than low-grade materials, especially in mobile or industrial environments.

Chemical incompatibility also leads to early failure. If the inner tube is not designed for the hydraulic fluid used, it may swell or soften internally. Temperature extremes further accelerate degradation in low-quality hoses, while premium hoses maintain flexibility and strength across wider ranges.

Many hose failures begin internally and show no visible warning signs. This makes initial hose quality and correct selection especially critical.

Advanced Testing Methods Used to Verify Hose Quality

Beyond visual inspection and specification review, advanced testing methods provide deeper insight into How to Tell If a Hydraulic Hose Is High Quality?. These tests are typically conducted by manufacturers but understanding them helps buyers recognize genuinely superior products.

Impulse testing is one of the most important evaluations. During this test, the hose is subjected to rapid pressure cycling that simulates years of real-world operation in a short period. High-quality hoses withstand millions of pressure impulses without leakage, reinforcement damage, or dimensional changes. Poor-quality hoses often fail early in this test due to weak bonding or inferior reinforcement.

Burst testing is another critical verification method. The hose is pressurized until failure, confirming whether it meets or exceeds its rated burst pressure. Premium hoses fail gradually and predictably, while inferior hoses may rupture violently at pressures far below advertised ratings.

Vacuum testing checks for internal leaks and liner integrity, especially important for suction applications. Environmental aging tests expose hoses to heat, oil, ozone, and UV radiation to evaluate long-term durability. High-quality hoses retain flexibility and strength after aging, while low-grade hoses harden, crack, or lose adhesion between layers.

Manufacturers that consistently perform and document these tests demonstrate strong quality control and engineering discipline.

Conclusion

Understanding How to Tell If a Hydraulic Hose Is High Quality? requires looking beyond price and appearance. True quality is revealed through material selection, reinforcement design, pressure ratings, flexibility, compatibility, testing, and supplier accountability. High-quality hydraulic hoses are engineered to perform consistently under demanding conditions, offering predictable service life and enhanced safety.

By selecting hoses that meet recognized standards, provide clear documentation, and demonstrate strong construction, operators can reduce downtime, protect equipment, and improve workplace safety. Investing in hose quality is not an expense—it is a long-term reliability strategy that pays dividends throughout the entire hydraulic system lifecycle.

FAQs

How can I tell if a hydraulic hose is high quality without laboratory testing?

You can evaluate material construction, reinforcement type, pressure ratings, clear labeling, flexibility, and supplier documentation. These indicators reveal most quality differences.

Is a thicker hydraulic hose always better?

Not necessarily. Hose quality depends on material formulation, reinforcement strength, and bonding—not just thickness.

Why do some hoses fail suddenly without visible damage?

Internal reinforcement fatigue, chemical incompatibility, or pressure spikes can cause hidden damage. High-quality hoses are designed to resist these internal failures longer.

How often should hydraulic hoses be replaced?

Replacement depends on application severity, inspection results, and manufacturer recommendations. High-quality hoses often support longer, more predictable service intervals.

Can high-quality hoses still fail?

Yes. Even premium hoses will fail if misapplied, incorrectly installed, or operated outside their rated limits.

Are branded hoses always higher quality?

Brand reputation helps, but true quality is confirmed through standards compliance, testing, and documented performance—not branding alone.