Selecting the right thread type is essential for ensuring a secure and leak-free connection in piping and fittings. Among the most commonly used thread types are BSPP (British Standard Pipe Parallel) and NPT (National Pipe Tapered). Although BSPP vs NPT threads might appear similar at first glance, they are based on different standards and have distinct characteristics that make them suitable for different applications. Understanding the differences between BSPP vs NPT is key to choosing the appropriate thread type for your specific needs.

What is BSPP?

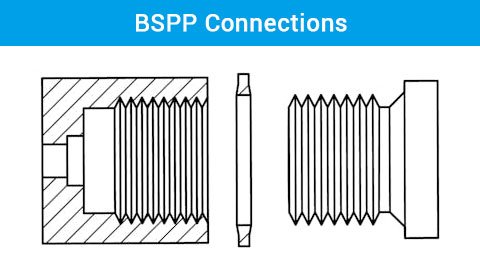

People commonly use BSPP, or British Standard Parallel Pipe, threads in Europe and the UK. BSPP threads are parallel, meaning the diameter remains consistent throughout the thread’s length. This type of thread relies on an O-ring or a sealing washer to create a tight seal. People often use BSPP threads in low-pressure systems because they can form reliable, leak-proof connections when properly installed.

Key Features of BSPP Threads:

- Parallel thread design

- Requires an O-ring or sealing washer for sealing

- Commonly used in hydraulic systems, plumbing, and other fluid transfer applications

- Widely adopted in Europe and other regions using British standards

What is NPT?

NPT, or National Pipe Tapered, is a thread standard primarily used in the United States. Unlike BSPP, NPT threads taper, decreasing in diameter as the thread lengthens. This tapering design lets NPT threads create a tight, self-sealing connection as you tighten them, usually without requiring an additional sealing component.

Key Features of NPT Threads:

- Tapered thread design

- Forms a seal through thread deformation as the connection is tightened

- Commonly used in high-pressure systems, gas lines, and fluid transfer applications

- Predominantly used in the United States and regions following American standards

BSPP vs NPT: Key Differences

- Thread Design:

- BSPP: Parallel threads, requiring an O-ring or sealing washer.

- NPT: Tapered threads, creating a seal through thread deformation.

- Sealing Mechanism:

- BSPP: Requires an additional sealing component for leak prevention.

- NPT: Self-sealing through the tapered thread design, typically without extra components.

- Regional Usage:

- BSPP: Common in Europe, the UK, and countries adhering to British standards.

- NPT: Predominantly used in the United States and countries following American standards.

- Application Suitability:

- BSPP: Often chosen for lower pressure systems where an O-ring can provide effective sealing.

- NPT: Preferred in high-pressure systems where a tighter seal is needed due to thread tapering.

Compatibility and Interchangeability

People often ask whether BSPP and NPT threads can be used interchangeably. The answer is generally no. Although both thread types serve similar applications, their differences in thread design and sealing mechanisms make them incompatible without adapters or modifications.

- Thread Angle: BSPP threads have a 55-degree thread angle, while NPT threads have a 60-degree angle. This difference affects how the threads engage and seal.

- Thread Design: BSPP’s parallel design fails to align with NPT’s tapered design, potentially causing leaks if paired incorrectly.

- Seal Type: As mentioned, BSPP requires an O-ring or sealing washer, while NPT forms a seal through thread deformation. Mixing these threads can compromise the seal and lead to connection failures.

Using the correct adapters allows for some compatibility, but experts generally recommend using the appropriate thread type for each application to ensure a secure and leak-free connection.

Choosing Between BSPP and NPT

When deciding between BSPP and NPT, several factors should be considered:

- Regional Standards: If your application is in a region that predominantly uses one standard over the other (e.g., NPT in the US or BSPP in Europe), it’s often easier and more cost-effective to use the locally accepted standard.

- Application Requirements: Consider the pressure requirements and sealing needs of your system. You might prefer NPT in high-pressure systems due to its tapered design, while BSPP works well in applications that require a reliable seal with an O-ring.

- Existing Infrastructure: If your current setup already uses a specific thread type, it’s usually simpler to continue with that standard to avoid compatibility issues.

- Industry Practices: Some industries may have a strong preference for one type of thread over the other due to historical usage or industry-specific standards.

Advantages and Disadvantages of BSPP

Advantages:

- Easy to Seal: BSPP’s parallel threads combined with an O-ring or sealing washer provide a reliable seal, making it easier to achieve leak-proof connections.

- Widely Used in Europe: BSPP is a standard in Europe, ensuring compatibility with a wide range of European fittings and components.

- Consistency: The parallel nature of BSPP threads ensures consistent engagement and even distribution of force along the connection.

Disadvantages:

- Requires Additional Sealing Components: BSPP threads need an O-ring or sealing washer, adding an extra component to the connection process.

- Less Suitable for High Pressure: BSPP may not be as effective in high-pressure systems where the tapering of NPT threads provides a tighter seal.

Advantages and Disadvantages of NPT

Advantages:

- Self-Sealing Design: NPT threads form a tight seal through their tapered design, reducing the need for additional sealing components.

- Widely Used in the US: NPT is the standard in the United States, making it the preferred choice for American industries and systems.

- Effective in High Pressure: The tapering of NPT threads allows for a strong, secure connection, ideal for high-pressure environments.

Disadvantages:

- Potential for Over-Tightening: Due to the tapered design, there is a risk of over-tightening NPT threads, which can lead to thread damage and potential leaks.

- Incompatibility with Parallel Threads: NPT threads are not compatible with BSPP threads without using adapters, limiting their flexibility in certain applications.

BSPP vs G Thread: Understanding the Difference

It’s important to note that BSPP is sometimes compared with G threads. However, BSPP and G threads are essentially the same, as both are parallel threads following the British Standard Pipe thread standard. The key difference is often in terminology, with “G” threads typically used in metric contexts.

Conclusion

Understanding the differences between BSPP and NPT threads, along with their compatibility, interchangeability, advantages, and disadvantages, is vital for ensuring proper fitting and optimal performance in various applications. By choosing the correct thread type for your needs, you can ensure secure, reliable, and leak-free connections that meet industry standards.

For more in-depth information on threaded connections and to explore our range of hydraulic fittings, visit our TASKE product catalog. Whether you need BSPP, NPT, or other types of fittings, we offer a wide selection to meet your specific requirements.

FAQ

Q1: What is the main difference between BSPP and NPT threads?

The main difference lies in their design: BSPP threads are parallel with a 55-degree angle, while NPT threads are tapered with a 60-degree angle. This difference affects their sealing mechanism and compatibility.

Q2: Can BSPP and NPT threads be used together?

No, BSPP and NPT threads are not directly compatible due to differences in thread design and angle. Using them together without adapters can lead to leaks and thread damage.

Q3: Which thread type is better for high-pressure applications?

NPT threads typically perform better in high-pressure applications because their tapered design naturally seals as the fitting tightens. However, BSPP threads also work well in high-pressure systems when paired with the appropriate sealing components.

Q4: Why do BSPP threads require an O-ring?

BSPP threads are parallel and do not create a seal on their own. An O-ring or washer is required to provide a leak-tight seal in BSPP connections.

Q5: Is BSPP more common in certain regions?

Yes, BSPP threads are more common in Europe and regions that follow the metric system, while NPT threads are more prevalent in North America.

Q6: What should I consider when selecting between BSPP and NPT threads?

Consider factors such as regional standards, application requirements, and the availability of fittings in your area. Compatibility with existing systems is also crucial.