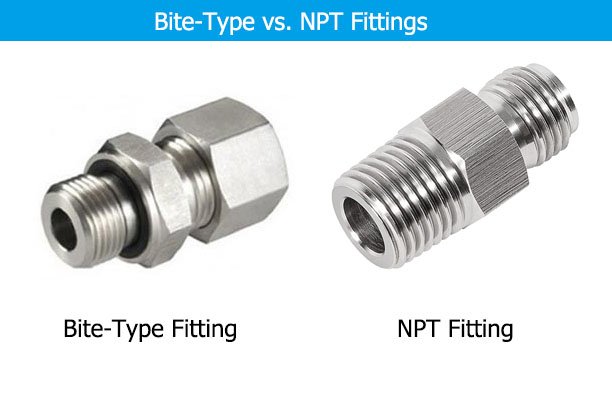

Introduction to Bite-Type and NPT Fittings

Fluid system designers and maintenance engineers often face a pivotal decision: which type of fitting ensures both safety and efficiency? In this context, understanding the bite-type vs. NPT fitting difference becomes more than a technical choice—it’s a key to reducing system failures, minimizing maintenance, and optimizing overall performance.

These two fittings differ significantly in design, application, pressure tolerance, and sealing mechanism. While they might seem interchangeable on the surface, each has specific advantages based on the use case. Let’s start by exploring what these fittings are and where they’re commonly used.

What is a Bite-Type Fitting?

Design and Construction

Bite-type fittings, also referred to as cutting ring fittings, are a type of compression fitting primarily used in hydraulic and pneumatic applications. Their design includes:

- Body: Holds the tube in place and contains the internal seating surface.

- Cutting Ring (Ferrule): Bites into the outer surface of the tube when the nut is tightened.

- Nut: Drives the cutting ring into the tube, creating the seal.

During installation, the cutting ring bites deeply into the tube wall, forming a strong, mechanical interlock. This bite is what sets this fitting apart—it ensures the connection can handle high-pressure environments with minimal risk of leaks.

Key Features and Functional Mechanism

- Metal-to-metal sealing: No reliance on additional sealants or O-rings.

- Vibration resistance: The strong bite into the tube makes these fittings ideal for high-vibration environments like mobile machinery or aircraft hydraulics.

- Reusable: With proper installation, bite-type fittings can be disconnected and reused, although the ferrule is typically a one-time-use component.

Materials and Sizing Options

Bite-type fittings are available in:

- Materials: Stainless steel (AISI 316), carbon steel (with zinc coating), and brass.

- Sizes: Typically from 6 mm to 42 mm (metric) and 1/4″ to 2″ (imperial), aligning with international standards like ISO 8434 and DIN 2353.

These fittings are especially common in applications requiring absolute precision and high-pressure endurance, such as in aerospace, oil & gas, marine systems, and automated manufacturing.

What is an NPT Fitting?

Thread Design and Working Principle

NPT, short for National Pipe Taper, is a U.S. standard for tapered threads used to join pipes and fittings. The thread profile is:

- Tapered at 1:16: Meaning the diameter of the thread reduces along the length.

- 60° thread angle: Designed to deform slightly upon tightening, ensuring a snug fit.

- Thread interference: As the male and female threads are engaged, the taper causes them to compress, providing the primary sealing mechanism.

However, this mechanical seal is rarely leak-tight on its own, hence requiring a thread sealant such as PTFE tape or anaerobic pipe dope to fill the micro-gaps.

Applications and Material Compatibility

NPT fittings are highly versatile and commonly used in:

- Water lines and plumbing systems

- Compressed air systems

- Natural gas and fuel lines (non-critical)

- Fire sprinkler systems

- HVAC and refrigeration setups

They are manufactured using materials such as brass, galvanized steel, black iron, stainless steel, and PVC, making them suitable for a broad range of non-corrosive to mildly corrosive environments.

Installation and Maintenance Needs

- Sealant dependency: Always require thread sealant to avoid leakage.

- Installation technique: Improper torque (either too tight or too loose) leads to leaks or thread damage.

- One-time use: Reinstalling used NPT fittings can compromise sealing due to deformed threads.

While they are cost-effective and widely accepted in residential and light commercial applications, their limitations become apparent in high-pressure or safety-critical environments.

Bite-Type vs. NPT Fitting Difference: Side-by-Side Comparison

Choosing the right fitting depends heavily on a clear understanding of their mechanical, operational, and performance differences. Below is an in-depth comparison that highlights their strengths and limitations:

Pressure Handling Capability

| Feature | Bite-Type Fittings | NPT Fittings |

|---|---|---|

| Pressure Rating | Up to 6000 psi or more (depending on material & tube size) | Typically up to 1500 psi; can vary |

| Pressure Stability | Excellent for pulsing or dynamic pressure systems | Moderate; risk of thread loosening under fluctuating pressure |

| Failure Mode | Less likely to leak if properly installed | Thread fatigue and sealant degradation common under pressure |

Verdict: Bite-type fittings clearly outperform NPT in high-pressure hydraulic and pneumatic systems due to their strong mechanical grip and robust sealing design.

Leak Resistance Performance

- Bite-Type: Offers superior leak resistance through a dual mechanism—mechanical lock (from the ferrule) and metal-to-metal contact.

- NPT: Relies entirely on thread interference and sealant. Any degradation of sealant leads to leaks, especially in systems with temperature fluctuations or vibration.

Installation Time and Skill Level

- Bite-Type: Requires skilled assembly, precise torque control, and properly prepared tubing. Improper installation (such as an uneven bite) can compromise the seal.

- NPT: Easier to install initially but prone to user errors such as over-tightening, under-tightening, or using insufficient sealant.

Key Insight: While NPT fittings are favored for their simplicity, they can be less forgiving in critical applications where consistent sealing is mandatory.

Cost and Economic Feasibility

- Initial Cost: NPT is more affordable upfront, often costing 30–50% less per fitting.

- Total Cost of Ownership: Bite-type fittings offer longer life, better reliability, and reduced leak-related downtime, offsetting their higher initial cost in long-term projects.

Advantages of Bite-Type Fittings

When evaluating fittings for performance-critical systems, bite-type fittings often stand out for a variety of engineering and operational reasons.

Where They Excel in Modern Systems

- Hydraulic Power Units (HPUs): High pressure, low tolerance for leaks.

- Aerospace: Lightweight, vibration-resistant, and extremely reliable under pressure differentials.

- Robotics & Automation: Demand for precision and reliability in confined assemblies.

- Marine Applications: High salt exposure environments benefit from the corrosion-resistant materials used in bite-type fittings.

Safety and Reliability Factors

- Zero-Leak Assurance: When installed properly, bite-type fittings are known for achieving “zero leak” benchmarks, a term not typically associated with NPT.

- No Sealant Dependency: Eliminates the risk associated with deteriorating sealants or improperly applied Teflon tape.

- Reduced Risk of Blow-off: The ferrule provides a firm mechanical hold that resists sudden disconnections or blow-offs under surges.

These features make bite-type fittings particularly well-suited for mission-critical systems where reliability and safety are non-negotiable.

Advantages of NPT Fittings

Despite their limitations, NPT fittings continue to be widely used—and for good reason. They offer compelling benefits for certain applications.

Cost Efficiency in Large Projects

- Budget-Friendly: For projects where thousands of connections are required, NPT fittings significantly reduce material costs.

- Low Learning Curve: Easy for general contractors and technicians to use without specialized training.

- Tool Compatibility: Universal tooling and thread standards make replacements and retrofits straightforward.

Accessibility and Market Availability

- Ubiquity: Available at virtually every hardware and plumbing store worldwide.

- Standardized Sizes: ANSI/ASME B1.20.1 threads are standard across the U.S., simplifying procurement and installation.

- Cross-compatibility: Can be paired with various pipe materials (e.g., galvanized, PVC, copper) with suitable adapters.

In summary, while NPT fittings may not shine in high-performance applications, they serve as an economical and practical solution for general-purpose fluid systems.

Disadvantages and Limitations of Both Fitting Types

While both fitting types have strong use cases, it’s important to understand their inherent weaknesses to avoid costly or dangerous failures in system design and operation.

Common Failure Points

- Bite-Type Fittings:

- Improper Installation: If the cutting ring doesn’t bite evenly or deeply enough, the seal will be compromised.

- Tube Surface Quality: Any irregularities, scratches, or dirt on the tube surface can interfere with the ferrule’s bite.

- Over-tightening: Excessive torque can distort the ferrule or tube, leading to misalignment.

- NPT Fittings:

- Thread Galling: Threads can seize during installation, especially with stainless steel, causing permanent damage.

- Leakage Over Time: Sealant dries, shrinks, or cracks, allowing leaks to form—especially under vibration or thermal cycling.

- Limited Reusability: Threads wear with repeated use, and previously sealed fittings can be hard to reseal properly.

Suitability Based on Environment

- Corrosive Environments: NPT fittings made from mild steel or iron can corrode easily; bite-type fittings in stainless steel offer better resistance.

- Dynamic Pressure Systems: NPT fittings may loosen over time, while bite-type fittings hold firm under vibration and shifting loads.

- Tight Spaces: Bite-type fittings, which don’t require as much rotational space, are often more suitable in cramped configurations.

Choosing Between Bite-Type and NPT: Which is Right for You?

Selecting the ideal fitting depends on more than just the budget. You need to assess operational needs, safety standards, and future maintenance expectations.

Application-Specific Recommendations

| Application | Recommended Fitting Type | Reason |

|---|---|---|

| High-pressure hydraulics | Bite-Type | Leak-proof, vibration-resistant |

| Low-pressure water systems | NPT | Cost-effective and simple |

| Marine or saltwater exposure | Bite-Type (stainless steel) | Corrosion resistance |

| DIY plumbing | NPT | Widely available and easy to use |

| Robotic arms or CNC hydraulics | Bite-Type | Precision sealing and compact design |

Longevity and Service Life Analysis

Bite-type fittings are designed for industrial applications where longevity and durability are critical. While NPT fittings may suffice in low-stress or residential applications, their dependency on thread sealant and susceptibility to wear make them less ideal for long-term industrial use.

- Bite-Type Fittings: 10–20+ years with minimal leaks if installed correctly.

- NPT Fittings: 5–10 years; often require re-tightening or resealing.

Industry Trends: Why Some Sectors Are Phasing Out NPT Fittings

Technological advancements and increased safety demands are changing the fitting landscape. Many sectors are re-evaluating traditional fitting options and moving toward higher performance alternatives.

Evolving Standards and Regulations

Several industries are now subject to stricter guidelines that favor fittings with greater reliability and fewer failure modes. For instance:

- ISO 8434 and DIN 2353 standards increasingly recommend compression fittings like bite-type.

- Aerospace and defense sectors mandate zero-leak tolerances, disqualifying NPT fittings due to their reliance on sealant and higher failure rates.

Push for Higher Reliability

Operational downtime costs money. As industries push for automation, uptime, and remote monitoring, the cost of a small leak can be enormous.

- Bite-type fittings, with their consistent sealing characteristics, are now standard in:

- Industrial robotics

- Renewable energy systems

- Precision fluid delivery systems

Even some sectors of oil and gas are turning toward hybrid fitting systems that integrate bite-type sealing for safety-critical areas.

Expert Tips for Choosing the Right Fitting

Selecting the correct fitting goes beyond product specs—it requires a thorough understanding of environmental conditions, pressure ratings, material compatibility, and regulatory constraints.

Installation Best Practices

For Bite-Type Fittings:

- Use tube deburring tools to smooth the ends before insertion.

- Ensure correct alignment before tightening the nut.

- Follow manufacturer torque recommendations strictly.

- Perform a test tightening with a gauge ring if possible.

For NPT Fittings:

- Wrap threads with Teflon tape in the direction of tightening (typically 2–3 wraps).

- Avoid over-tightening; turn 1–2 more times after hand-tight.

- Inspect threads for galling or wear before reusing.

How to Avoid Costly Mistakes

- Don’t mix systems: Never use a bite-type fitting on a threaded pipe, or vice versa.

- Avoid incompatible materials: For example, don’t use stainless NPT fittings with aluminum threads without anti-galling compound.

- Use correct tubing: Bite-type fittings require seamless or precisely cut tubing for a secure bite.

- Inspect for alignment: Misaligned joints cause leaks and reduce mechanical strength.

These tips can prevent system failures and ensure optimal sealing performance for years.

Conclusion

Understanding the bite-type vs. NPT fitting difference empowers engineers, technicians, and system designers to build safer, more efficient, and longer-lasting fluid systems. Whether your goal is to meet strict industry standards or to optimize for cost and speed, each fitting type has its place—when used correctly.

FAQs

Q1: Can bite-type fittings be reused?

A: The fitting body and nut can often be reused, but the ferrule should not be reused as it loses its cutting ability after the first installation.

Q2: Are bite-type fittings compatible with plastic tubing?

A: No. They are designed for use with metal tubing only, typically stainless steel or carbon steel.

Q3: Why are my NPT fittings still leaking after using Teflon tape?

A: Common causes include insufficient tape, over-tightening, or worn threads. Consider switching to a higher-performance sealant or compression fitting.

Q4: Which fitting is better for vibration-prone environments?

A: Bite-type fittings are superior due to their strong grip and lack of dependency on thread friction.

Q5: Do bite-type fittings require special tools?

A: No specialized tools are needed, but clean cuts, proper torque, and deburring tools are essential for proper installation.

Q6: Are there standards governing the use of these fittings?

A: Yes. Bite-type fittings often comply with DIN 2353 or ISO 8434, while NPT fittings follow ASME B1.20.1 or ANSI standards.