Barb fittings are widely used in plumbing, irrigation, and automotive applications for connecting hoses and tubing. They’re simple, cost-effective, and reliable—but like any connection, they can sometimes leak. If you’ve been scratching your head wondering, “Do barb fittings leak?” this article is your go-to guide. We’ll walk you through why leaks happen, how to fix them, and what you can do to prevent leaks in the future.

What Are Barb Fittings and How Do They Work?

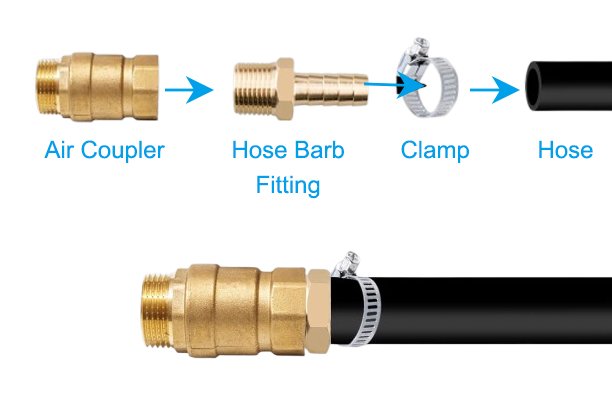

Barb fittings are small, cylindrical connectors with ridges (or “barbs”) that help secure hoses or tubing. They’re typically made of plastic, brass, or stainless steel, making them versatile for different systems, whether you’re working on irrigation, fuel lines, or water supply systems.

Here’s how they work:

- The barb ridges create friction: When a hose is pushed over the barbs, the ridges grip the inner surface of the hose.

- Clamps reinforce the seal: To secure the connection further, clamps are added, compressing the hose tightly against the barb.

While barb fittings are reliable, they’re not foolproof. Leaks can happen if something’s amiss.

Common Reasons Barb Fittings Leak

Barb fittings are designed to create a secure, watertight seal, but leaks can still happen if certain factors go wrong. To prevent or fix leaks, it’s crucial to understand what causes them in the first place. Below, we’ve outlined the most common culprits behind a leaking barb fitting:

1. Improper Installation

- One of the most frequent causes of leaks is an installation error. If the hose isn’t pushed all the way onto the barb, or if it’s not seated evenly, small gaps can form, allowing fluids to escape.

- Similarly, if the clamp isn’t tightened properly—or if you forget to use one altogether—the fitting won’t be able to withstand pressure, causing leaks.

2. Worn-Out or Damaged Hose

- Hoses naturally degrade over time, especially if they’re exposed to heat, UV rays, chemicals, or excessive pressure. Cracks, splits, or stretching in the hose material can result in a poor seal around the barb fitting.

- A hose that has been reused multiple times might have become loose, compromising the grip of the barb ridges.

3. Using the Wrong Size Components

- A mismatch between the barb fitting and the hose diameter is a recipe for leaks. If the hose is too large, it won’t grip the barbs securely. If it’s too small, it may tear during installation or fail to seat correctly.

- The wrong clamp size can also cause problems—too small, and it won’t fit around the hose; too large, and it won’t provide sufficient compression.

4. Inadequate Clamping

- Clamps are essential for reinforcing the connection, especially in high-pressure systems. A clamp that’s too loose can’t compress the hose tightly around the barb, leaving room for leaks. On the other hand, over-tightening can damage the hose or deform the fitting.

5. Excessive Pressure in the System

- Every fitting and hose has a pressure limit. If the pressure in your system exceeds the rating of the barb fitting or hose, the connection may fail, resulting in leaks. Sudden pressure spikes are especially problematic.

6. Material Incompatibility

- The materials used for the hose and the barb fitting need to match the demands of the system. For example, using a plastic barb fitting with a rubber hose in a high-temperature application may cause the materials to degrade, leading to leaks.

7. Environmental Factors

- Harsh environments—like extreme temperatures, exposure to chemicals, or prolonged sunlight—can weaken the materials in both the fitting and the hose. This wear and tear eventually leads to leaks.

8. Threaded Barb Fittings Without Sealant

- If your barb fitting is threaded, skipping plumber’s tape or thread sealant can allow leaks to develop at the threaded connection, even if the hose-to-barb seal is perfect.

How to Fix a Leaking Barb Fitting

When a barb fitting starts to leak, don’t panic—it’s usually a simple fix. Follow these steps to troubleshoot and repair the leak:

1: Turn Off the System

- Before you start, shut off the water, air, or fluid supply to the system. Relieve any built-up pressure to avoid accidents or further damage during the repair process.

2: Inspect the Fitting and Hose

- Disconnect the hose from the barb fitting and examine both for signs of damage.

- Check the hose for cracks, splits, or stretching.

- Look at the barb fitting for wear, corrosion, or deformation.

- If either component shows damage, replace it before reassembling.

3: Replace a Damaged Hose (If Needed)

- If the hose is worn out or stretched, use a new one. Make sure the replacement hose has the correct inner diameter to fit snugly over the barb.

4: Reinstall the Hose Properly

- Push the hose all the way onto the barb fitting until it covers all the ridges. Ensure the hose sits flush with the base of the barb for maximum grip.

5: Add and Secure a Clamp

- Slide a hose clamp over the connection and position it just behind the last barb ridge. This placement provides optimal compression and prevents the hose from slipping.

- Tighten the clamp evenly using a screwdriver or nut driver. Be careful not to overtighten, as this could damage the hose or fitting.

6: Apply Thread Sealant (If Using Threaded Fittings)

- For threaded barb fittings, apply plumber’s tape or a liquid thread sealant to the threads before reconnecting the fitting. This extra layer helps prevent leaks at the threaded joint.

7: Test the Connection

- Turn the system back on and slowly increase pressure while monitoring the fitting for leaks. If you notice any drips, tighten the clamp slightly or recheck the installation.

8: Upgrade Components (If Needed)

- If leaks persist or your system frequently exceeds the rated pressure, consider upgrading to higher-quality materials, such as metal fittings or reinforced hoses.

When to Replace Barb Fittings or Hoses

Knowing when to replace these components is essential to maintaining a leak-free system and avoiding costly damage or downtime. Let’s explore the key signs that indicate it’s time to replace your barb fittings or hoses.

1. Cracks or Damage in the Hose

Over time, hoses are exposed to wear and tear from pressure, temperature, and environmental factors. If you notice any of the following signs, it’s time to replace the hose:

- Visible cracks or splits along the length of the hose.

- Bulges, which indicate internal damage or weakening.

- Fraying or soft spots, especially at the connection points.

Why it Matters: A damaged hose won’t form a proper seal around the barb, leading to leaks or even complete system failure under pressure.

2. Stretching or Loose Fit

Hoses can stretch out over time, especially when subjected to high pressure or repeated reconnections. A loose-fitting hose won’t grip the barb ridges properly, even with a clamp.

Signs of Stretching:

- The hose feels too loose when pushed onto the barb.

- You notice the hose sliding off easily, even after tightening the clamp.

What to Do: Replace the hose with one that fits snugly over the barb fitting. Ensure you’re using the correct size and material for your application.

3. Corrosion or Damage to Barb Fittings

Barb fittings, especially those made from metal (like brass or stainless steel), can corrode or degrade over time, particularly in harsh environments.

Look for:

- Rust or discoloration on metal fittings.

- Cracks or chips in plastic barb fittings.

- Bent or deformed barb ridges.

Why Replace? Corrosion weakens the fitting, compromising the seal and reducing its durability. A damaged barb fitting won’t hold the hose securely, leading to leaks.

4. Repeated Leaks Despite Repairs

If you’ve already tightened clamps, replaced hoses, or applied thread sealant but the connection keeps leaking, it’s a sign that one or more components are worn out.

Possible Culprits:

- The barb fitting has become deformed or worn smooth, reducing its ability to grip the hose.

- The hose material has degraded, making it impossible to achieve a tight seal.

Solution: Replacing the fitting or hose is often the most effective fix. Persistent leaks can also indicate that the components aren’t suited to your system’s pressure or temperature demands.

5. Changes in System Pressure or Application

If you’ve upgraded your system (e.g., increased pressure, switched to higher temperatures, or started using different fluids), the existing barb fittings or hoses might not be able to handle the new requirements.

When to Replace:

- If the fittings or hoses were originally rated for lower pressures.

- If the new application involves chemicals or temperatures that could degrade the existing materials.

Tip: Always check the manufacturer’s specifications to ensure compatibility with the new system parameters.

6. Age and Wear

Even if everything appears fine, hoses and fittings have a lifespan and should be replaced periodically as part of routine maintenance.

General Guidelines for Lifespan:

- Rubber or PVC Hoses: 2–5 years, depending on use and exposure to environmental factors.

- Plastic Barb Fittings: 5–10 years, though they may degrade faster in sunlight or extreme temperatures.

- Metal Barb Fittings: 10+ years, depending on the environment (e.g., exposure to moisture or corrosive substances).

Preventive Replacement: If your system is older and has components nearing the end of their expected lifespan, it’s better to replace them proactively than wait for a failure.

7. Visible Wear on Clamps or Seals

Sometimes, leaks around barb fittings aren’t caused by the hose or the fitting itself, but by the clamps or seals that reinforce the connection.

Signs to Watch For:

- Rusted or corroded clamps.

- Cracked or missing seals (if used).

- Clamps that no longer tighten securely.

What to Do: Replace clamps or seals as part of routine maintenance. For long-term reliability, opt for high-quality stainless steel clamps.

Tips to Prevent Barb Fittings from Leaking

Prevention is better than cure, right? Here are some tips to keep your barb fittings leak-free:

- Choose the Right Size: Always use hoses and barbs that are compatible in size. The fit should be snug without being overly tight.

- Use Quality Materials: Opt for high-quality fittings and hoses that can withstand your system’s pressure, temperature, and environmental conditions.

- Double-Check Installation: When installing a barb fitting, ensure the hose is pushed all the way onto the barb and secured with a clamp.

- Perform Routine Inspections: Regularly inspect your system for signs of wear and tear. Replace any components showing signs of damage.

- Consider Thread Sealant: If you’re using threaded barb fittings, apply thread sealant or plumber’s tape to the threads to prevent leaks.

Conclusion

So, do barb fittings leak? The short answer is yes, they can—but with proper installation, quality materials, and regular maintenance, leaks are easily avoidable. By understanding the common causes of leaks and following the tips shared in this guide, you can ensure a long-lasting and leak-free connection for your system.

Whether you’re working on a home plumbing project, setting up an irrigation system, or repairing automotive lines, taking the time to install barb fittings correctly will save you a lot of hassle in the long run.

FAQs

1. Why do barb fittings leak?

Barb fittings can leak due to improper installation, worn-out or damaged hoses, incorrect sizing of components, inadequate clamping, excessive system pressure, or material incompatibility.

2. How do I stop a barb fitting from leaking?

To fix a leak, inspect the hose and fitting for damage, push the hose fully onto the barb, secure it with a hose clamp, and ensure the system’s pressure is within the fitting’s rating. For threaded fittings, use plumber’s tape on the threads.

3. Do I need a clamp for barb fittings?

Yes, using a clamp is highly recommended. It reinforces the connection by compressing the hose tightly around the barb, reducing the chances of leaks, especially in high-pressure systems.

4. Can barb fittings handle high-pressure systems?

Barb fittings can handle pressure to a certain extent, but their capacity depends on the material and design. Metal fittings (like brass or stainless steel) can handle higher pressure than plastic ones. Always check the manufacturer’s specifications.

5. What size hose should I use with a barb fitting?

The inner diameter of the hose should match the outer diameter of the barb fitting. A snug fit ensures the barbs grip the hose securely, preventing leaks.

6. How can I prevent leaks in barb fittings?

Use properly sized hoses and fittings, quality materials, clamps for reinforcement, and thread sealant for threaded connections. Regularly inspect the system for wear and tear to replace worn components before leaks occur.