D.O.T Approved Push-to-connect fittings are a revolutionary innovation in pneumatic systems, simplifying connections between air brake lines. Designed for efficiency and reliability, these fittings are critical components in vehicles requiring compressed air systems for braking. Their ease of use eliminates the need for wrenches, reducing labor time and ensuring secure connections.

What Does D.O.T Approval Mean?

The Department of Transportation (D.O.T.) approval ensures that fittings meet stringent safety and performance standards. Consequently, for air brake systems, this certification guarantees that the product is capable of withstanding high-pressure environments, extreme temperatures, and continuous use without failure.

D.O.T.-approved push-to-connect fittings must:

- Endure pressures above 150 PSI.

- Use materials that resist corrosion and degradation.

- Adhere to FMVSS 571.106 regulations, ensuring safe and reliable operations in heavy-duty vehicles.

Key Features of D.O.T Approved Fittings

D.O.T.-approved push-to-connect fittings offer a range of features, including:

- Durability: Made from robust materials like brass and composite plastics.

- Pressure Resistance: Engineered to handle high operating pressures and fluctuations.

- Sealing Technology: O-ring seals that prevent leaks while maintaining quick-disconnect functionality.

How Push-to-Connect Fittings Work

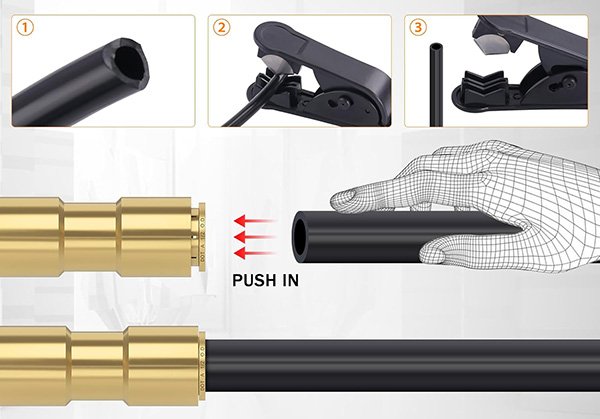

Push-to-connect fittings revolutionize the way pneumatic connections are made in air brake systems. Their intuitive design eliminates the need for complex tools, sealants, or time-consuming assembly processes. Moreover, by using a straightforward push-and-lock mechanism, these fittings provide a secure and reliable connection in seconds. Here’s a detailed look at how they work:

1. Simple Tube Insertion

The process starts by inserting a prepared tube into the fitting. The tube should be cut cleanly and squarely to ensure a perfect fit. Once inserted, the tube slides into the fitting until it reaches a stop or clicks into place. This audible or tactile feedback indicates that the connection is secure.

2. Internal Sealing Mechanism

The magic of push-to-connect fittings lies in their internal sealing design:

- O-Ring Seals: Located inside the fitting, O-rings form an airtight seal around the tube. These seals prevent leaks and ensure that air pressure remains constant within the brake system.

- Gripping Teeth: Surrounding the tube is a series of gripping mechanisms, often made of stainless steel or similar durable materials. These teeth bite into the tube, holding it securely in place and, consequently, preventing it from dislodging under pressure.

3. Pressure Resistance

Push-to-connect fittings are engineered to handle high-pressure environments, typically up to 150 PSI or more. The combination of O-rings and gripping mechanisms ensures that the fitting remains sealed and secure, even under dynamic conditions such as braking or rapid pressure changes.

4. Easy Release

To disconnect the tubing, simply press the release collar on the fitting. Consequently, this action disengages the gripping mechanism, allowing the tube to be pulled out without damaging the fitting or the tubing.

5. Reusability

Unlike traditional fittings that may require cutting off tubing or replacing seals, push-to-connect fittings are reusable. As long as the fitting and tubing remain undamaged, you can disconnect and reconnect the components multiple times, saving time and resources.

Advantages in Air Brake Systems

- Speed: The push-to-connect design cuts installation time significantly, especially in large fleets or systems with multiple connections.

- Simplicity: By removing the need for tools and sealants, these fittings reduce the chances of installation errors.

- Reliability: The secure locking and sealing mechanisms ensure consistent performance in high-pressure environments. Therefore, users can rely on the durability and effectiveness of these systems under demanding conditions.

How Compression Fittings Work

Compression fittings consist of three main components:

- Nut: The nut is threaded onto the fitting body and compresses the ferrule when tightened.

- Ferrule: A ring-shaped component that provides the seal by compressing against the tube and fitting body.

- Fitting Body: The main component that houses the ferrule and connects to the system.

Installation Process:

- Step 1: Insert the Tube: The tube is inserted into the fitting body.

- Step 2: Position the Ferrule: The ferrule is placed around the tube inside the nut.

- Step 3: Tighten the Nut: The nut is tightened onto the fitting body, causing the ferrule to compress. This compression creates a tight seal and secures the tube in place.

Benefits of Compression Fittings

- High-Pressure Handling: Compression fittings withstand extreme pressures, making them suitable for demanding applications like air brake systems.

- Durability: Built from robust materials such as brass, stainless steel, or aluminum, these fittings resist wear, corrosion, and vibration.

- Leak Resistance: The compression mechanism forms a reliable seal, reducing the risk of air leaks.

- Versatility: Compatible with a wide range of tubing materials, including metal and rigid plastics.

Challenges with Compression Fittings

While compression fittings are dependable, they have a few drawbacks compared to modern alternatives like push-to-connect fittings:

- Installation Complexity: Requires tools such as wrenches and can be time-consuming.

- Permanent Connections: Once installed, the ferrule often deforms, making the connection semi-permanent. Reuse can be challenging without replacing the ferrule.

- Risk of Over-Tightening: Excessive tightening can damage the fitting or tube, leading to failure.

Applications in Air Brake Systems

Compression fittings are commonly used in:

- Primary Air Lines: Handling the main flow of compressed air to brake chambers.

- Heavy-Duty Applications: Suitable for systems requiring high reliability and pressure resistance, such as commercial trucks and industrial equipment.

- Older Vehicles: Often found in legacy systems where push-to-connect fittings were not standard.

Comparison to Push-to-Connect Fittings

| Feature | Compression Fittings | Push-to-Connect Fittings |

|---|---|---|

| Installation Time | Slower | Faster |

| Tools Required | Wrenches | None |

| Reusability | Limited | High |

| Leak Resistance | High | Very High |

Materials Used in D.O.T Approved Fittings

- Brass: Offers high strength and corrosion resistance.

- Composite Plastics: Lightweight yet durable, suitable for high-temperature environments.

- Stainless Steel: Provides superior resistance to wear and chemical exposure, albeit at a higher cost.

Installation Process

- Preparation: Inspect and clean the tubing to avoid contamination.

- Cut and Measure: Ensure proper tube length for a secure fit.

- Push and Lock: Insert the tube firmly into the fitting until it locks in place.

- Testing: Pressurize the system to check for leaks.

Common Challenges and Solutions

- Leaks: Caused by improper cuts or damaged O-rings. Solution: Re-cut tubing and ensure proper alignment.

- Corrosion: Regular inspection and replacement prevent material degradation.

- Fitting Damage: Replace fittings showing cracks or excessive wear.

Maintenance and Inspection Tips

- Conduct regular pressure tests.

- Inspect seals for wear and replace damaged components.

- Lubricate O-rings periodically to enhance longevity.

Comparison with Traditional Fittings

| Feature | Push-to-Connect | Traditional |

|---|---|---|

| Installation Time | Faster | Slower |

| Tools Required | None | Wrenches or sealants |

| Leak Resistance | High | Moderate |

| Reusability | Easy to disconnect | Time-consuming |

Safety and Compliance Guidelines

To ensure safety:

- Use only D.O.T.-certified fittings.

- Perform routine inspections and replace worn-out components.

- Maintain detailed records of fittings used in critical systems.

Top Manufacturers and Brands

Leading brands offering high-quality, D.O.T.-approved fittings include:

- Parker Hannifin

- Eaton

- Weatherhead

- SMC Pneumatics

Cost Considerations

Prices range from $5 to $30 per fitting, influenced by:

- Material type (brass vs. plastic).

- Size and specifications.

- Manufacturer reputation.

FAQs

1. Are push-to-connect fittings safe for air brake systems?

Yes, D.O.T.-approved fittings are designed to meet strict safety standards for air brake applications.

2. Can I reuse push-to-connect fittings?

Most fittings can be reused if undamaged, though seals may need replacement over time.

3. What materials are best for heavy-duty applications?

Brass and stainless steel are preferred for their durability and corrosion resistance.

4. How do I identify D.O.T.-approved fittings?

Look for the D.O.T. stamp or approval markings on the fittings.

5. Can push-to-connect fittings handle extreme temperatures?

Yes, D.O.T.-approved fittings are engineered to perform in a wide temperature range.

6. What is the lifespan of these fittings?

With proper maintenance, they can last for several years, depending on usage conditions.