Hydraulic system maintenance is essential for keeping the machinery that powers industries like construction, agriculture, and manufacturing running smoothly. These systems handle heavy-duty tasks with precision, but without regular upkeep, even minor issues like leaks or contamination can escalate into costly repairs and prolonged downtime. Having the right tools for hydraulic system maintenance not only ensures peak performance but also extends equipment life, enhances safety, and minimizes unexpected breakdowns.

In this guide, we’ll explore the essential tools for hydraulic system maintenance, breaking down their purposes, advantages, and how they can transform your maintenance routine. So, if you’re ready to give your hydraulic systems the TLC they deserve, let’s dive in.

Why Hydraulic System Maintenance Matters

Hydraulic systems are the lifeblood of many industries, and their maintenance is crucial for several reasons:

- Reduced Downtime: Regular maintenance prevents unexpected breakdowns that can stall operations.

- Cost Efficiency: Catching issues early saves you from expensive repairs or replacements.

- System Longevity: Proper care extends the lifespan of your equipment.

- Safety: Well-maintained systems minimize the risk of accidents caused by pressure leaks or malfunctions.

Without the right tools, however, even the most diligent maintenance schedule can fall flat. Let’s look at the tools that’ll help you stay on top of hydraulic maintenance.

1. Hydraulic Wrenches and Torque Tools

A solid hydraulic system starts with leak-free connections. For that, you need hydraulic wrenches and torque tools.

Why They’re Essential:

- These tools ensure that fittings, hoses, and connections are tightened to precise specifications.

- They prevent over-tightening, which can damage fittings, and under-tightening, which can lead to leaks.

Types to Consider:

- Torque Wrenches: Ensure consistent and accurate tightening.

- Adjustable Wrenches: Offer versatility for a variety of bolt and nut sizes.

- Hydraulic Nut Splitters: Perfect for removing seized or corroded nuts without damaging surrounding components.

Pro Tip: Always check the torque specifications provided by the manufacturer to avoid over-tightening.

2. Hydraulic Fluid Analysis Kits

Hydraulic fluid is the lifeblood of your system. Keeping it clean and free from contamination is non-negotiable.

Why They’re Essential:

- Contaminated fluid can cause severe damage to pumps, valves, and other components.

- Regular analysis helps you spot issues like water contamination, air entrainment, or particle buildup.

Key Features to Look For:

- Portable Fluid Test Kits: Ideal for on-site fluid analysis.

- Particle Counters: Measure the level of contamination in hydraulic fluid.

- Moisture Meters: Detect water contamination, which can corrode internal components.

Pro Tip: Set up a schedule to test your hydraulic fluid every 1,000 hours of operation or as recommended by your manufacturer.

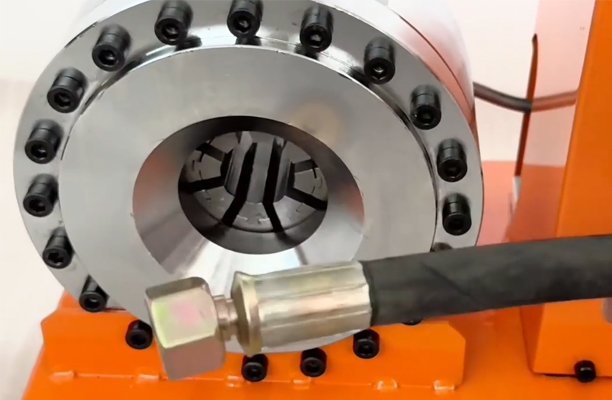

3. Hydraulic Hose Crimpers and Cutters

When it comes to replacing or repairing hydraulic hoses, having the right crimping and cutting tools is a game-changer.

Why They’re Essential:

- Crimpers ensure secure connections between hoses and fittings, reducing the risk of leaks.

- Proper cutters provide clean cuts, which are crucial for fitting installation.

Types to Consider:

- Handheld Hose Crimpers: Compact and portable for fieldwork.

- Bench-Mounted Crimpers: Better for workshop settings with heavy-duty applications.

- Hose Cutters: Designed to make clean, precise cuts without fraying the hose material.

Pro Tip: Always match the crimper and fittings to the hose type and diameter for a leak-proof connection.

4. Pressure Gauges and Test Kits

Hydraulic systems operate under high pressure – and keeping that pressure within specified limits is vital for safety and performance.

Why They’re Essential:

- Pressure gauges allow you to monitor system pressure and diagnose issues like leaks or blockages.

- Test kits help measure flow rates and identify inefficiencies.

Key Features to Look For:

- Digital Gauges: Offer precise readings and are easier to interpret than analog ones.

- Pressure Test Kits: Typically include hoses, connectors, and gauges to test various system components.

- Flow Meters: Check flow rates to ensure the system is operating at optimal performance levels.

Pro Tip: Keep an eye out for sudden drops or spikes in pressure – they’re often early warning signs of system issues.

5. Hydraulic Cylinder Tools

Hydraulic cylinders are the workhorses of any hydraulic system, and their maintenance requires specific tools.

Why They’re Essential:

- They help you disassemble, reassemble, and troubleshoot hydraulic cylinders efficiently.

- These tools ensure precision, reducing the chances of damaging components during maintenance.

Tools to Keep Handy:

- Cylinder Repair Kits: Include tools like seal pullers, gland nut wrenches, and snap ring pliers.

- Hydraulic Piston Seal Installation Tools: Simplify the process of installing new seals without damaging them.

- Bench Vises: Secure the cylinder during repairs, allowing for better control and precision.

Pro Tip: Always inspect hydraulic cylinders for wear, corrosion, or leaks during routine maintenance.

6. Filtration Units

Clean hydraulic fluid is critical for system performance. Portable filtration units help keep contaminants at bay.

Why They’re Essential:

- They remove particles and water from hydraulic fluid, extending the life of pumps, valves, and other components.

- Regular filtration reduces the risk of system failure caused by contamination.

Types to Consider:

- Portable Filtration Carts: Ideal for on-site fluid cleaning.

- Inline Filtration Units: Installed directly in the system to continuously filter fluid.

- Desiccant Breathers: Prevent contaminants from entering through the reservoir vent.

Pro Tip: Pair filtration units with fluid analysis to maintain optimal cleanliness levels.

7. Contamination Monitors

Monitoring contamination in real time gives you a proactive edge in maintaining your hydraulic system.

Why They’re Essential:

- They provide instant feedback on fluid cleanliness, allowing you to take action before problems escalate.

- Real-time monitoring is particularly useful for high-demand applications where downtime isn’t an option.

Features to Look For:

- Portable Contamination Monitors: Perfect for quick checks during maintenance rounds.

- Online Monitoring Systems: Provide continuous contamination data directly from the system.

Pro Tip: Combine contamination monitors with filtration units for a comprehensive fluid cleanliness strategy.

8. Heat Guns and Thermometers

Temperature plays a huge role in hydraulic system performance. Overheating can lead to fluid degradation, seal damage, and even component failure.

Why They’re Essential:

- Heat guns and thermometers help you monitor operating temperatures to avoid overheating.

- Identifying hot spots can also pinpoint inefficiencies in the system.

Key Tools to Consider:

- Infrared Thermometers: Allow for quick, non-contact temperature checks.

- Heat Guns: Useful for controlled heating during repairs.

Pro Tip: Always ensure your hydraulic fluid and system components are operating within the manufacturer’s recommended temperature range.

9. Seal and O-Ring Kits

Leaks are the enemy of any hydraulic system, and seals and O-rings are your first line of defense.

Why They’re Essential:

- They’re necessary for replacing worn or damaged seals to restore leak-free performance.

- A well-stocked kit ensures you have the right size and material for any repair.

Key Considerations:

- Opt for kits that include a variety of sizes and materials (e.g., NBR, Viton, EPDM).

- Always choose seals compatible with your system’s hydraulic fluid.

Pro Tip: Store seal kits in a cool, dry place to prevent degradation before use.

10. Safety Equipment

Last but not least, don’t overlook the importance of safety gear during hydraulic maintenance.

Why It’s Essential:

- High-pressure systems can be dangerous, and personal protective equipment (PPE) minimizes risk.

Must-Have Safety Gear:

- Safety Goggles: Protect your eyes from hydraulic fluid sprays.

- Gloves: Resistant to oil and high temperatures.

- Protective Clothing: Shields your skin from accidental spills.

- Hearing Protection: Useful when working around loud hydraulic pumps.

Pro Tip: Always release system pressure before starting maintenance to avoid accidental injuries.

Conclusion

Having the right tools for hydraulic system maintenance isn’t just a convenience – it’s a necessity. From wrenches and crimpers to fluid analysis kits and contamination monitors, these tools empower you to keep your systems running smoothly and efficiently. Remember, regular maintenance combined with proper tools ensures safety, minimizes downtime, and extends the life of your hydraulic equipment.

FAQs

1. How often should hydraulic systems be maintained?

It depends on the equipment and application, but most systems require maintenance every 500 to 1,000 operating hours or as specified by the manufacturer.

2. What’s the most common cause of hydraulic system failure?

Contaminated fluid is the leading cause. That’s why regular fluid analysis and filtration are so important.

3. Can I use regular tools for hydraulic maintenance?

No, hydraulic systems require specialized tools to ensure precision, safety, and efficiency.

4. How do I know if my hydraulic fluid is contaminated?

Common signs include sluggish performance, overheating, and visible debris in the fluid. A fluid analysis kit can confirm contamination levels.

5. What should I do if I notice a leak?

Immediately shut down the system, relieve pressure, and identify the source. Replace damaged seals, hoses, or fittings as necessary.

6. What are the signs my hydraulic system needs maintenance?

Look out for these red flags:

- Unusual noises like knocking or hissing.

- Reduced performance or slower operations.

- Visible leaks around hoses or fittings.

- Overheating beyond normal operating temperatures.

- Discolored or foamy fluid, indicating contamination or air bubbles.