Let’s face it: when it comes to industrial piping systems, small components like ferrule fittings often fly under the radar, but their role is absolutely pivotal. They’re the unsung heroes that ensure piping systems operate seamlessly without leaks or interruptions, saving time, money, and headaches.

Ferrule fittings might not look like much, but their efficiency, durability, and versatility make them essential across countless industries like oil and gas, chemical processing, and even HVAC systems. But what exactly are they? How do they work? And what makes them so crucial in industrial setups?

In this ultimate guide, we’ll explore every aspect of ferrule fittings—from their core functionality and applications to their types, benefits, and installation tips. Whether you’re new to the world of industrial piping or a seasoned engineer looking for a refresher, this guide will provide all the details you need. Let’s get started!

What Are Ferrule Fittings?

At their core, ferrule fittings are specialized mechanical connectors designed to ensure that piping and tubing systems are securely joined, eliminating the risk of leaks. They’re engineered to maintain a tight seal, even in high-pressure or high-temperature environments.

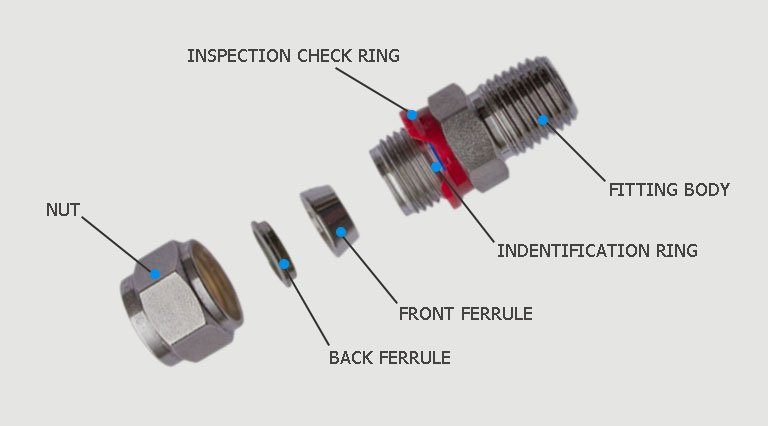

Ferrule fittings are composed of three key components:

- Body: This is the main housing of the fitting and provides structural support.

- Nut: The nut is tightened over the body to secure the connection.

- Ferrule(s): Typically made of metal, the ferrule(s) clamp against the tubing to form a leak-proof seal. Double ferrule systems use two ferrules (a front ferrule and a back ferrule) for added grip and security.

How Do They Work?

When you tighten the nut, the ferrule(s) compress against the pipe or tubing. This compression creates a strong, reliable seal that prevents any leakage, even under extreme conditions. Unlike traditional threaded fittings, ferrule fittings don’t require additional sealing agents like Teflon tape or thread sealant.

They come in various sizes, materials, and configurations, making them suitable for a diverse range of applications.

Key Features of Ferrule Fittings

1. Leak-Proof Sealing

Ferrule fittings are renowned for their ability to provide leak-proof connections, even in high-pressure systems. Moreover, the double ferrule design adds an extra layer of sealing, ensuring that no fluid escapes the system.

2. Corrosion Resistance

Many ferrule fittings are made from stainless steel or other corrosion-resistant materials, making them ideal for handling harsh chemicals or being used in environments prone to rust and corrosion.

3. Ease of Installation

No need for complicated tools or advanced skills— They are designed for quick and hassle-free installation. You can assemble and disassemble them without any special expertise.

4. Wide Material Compatibility

Ferrule fittings can work with various tubing materials, including stainless steel, copper, and even plastic, making them versatile across industries.

5. Long-Term Durability

Thanks to their sturdy design and robust materials, ferrule fittings can withstand years of use, even in demanding industrial settings.

6. Reusable Design

One of the standout features of ferrule fittings is their reusability. Unlike welded joints or glued fittings, ferrule fittings can be disassembled, inspected, and reused without sacrificing performance.

Applications of Ferrule Fittings

1. Oil and Gas Industry

Oil and gas pipelines often operate under high pressure, where even a small leak can lead to catastrophic consequences. Therefore, ferrule fittings are a trusted solution for maintaining leak-proof connections in these high-stakes environments.

- Used in upstream, midstream, and downstream operations.

- Handle both gases and liquids with ease.

2. Chemical Processing

In the chemical industry, which involves the transfer of corrosive and hazardous substances, ferrule fittings play a crucial role. Specifically, these fittings are designed to resist chemical damage and provide safe, reliable connections in harsh conditions.

- Ideal for reactors, storage tanks, and transport pipelines.

- Ensures worker safety and product integrity.

3. HVAC Systems

Heating, ventilation, and air conditioning systems rely on ferrule fittings to create reliable connections in their piping systems. Consequently, these fittings ensure efficient air and fluid flow, thereby preventing energy losses.

- Used in both commercial and residential setups.

4. Pharmaceutical and Food Industries

In industries where cleanliness and sterility are critical, ferrule fittings help maintain contamination-free environments.

- Used in biopharmaceutical production lines.

- Ideal for transporting sterile fluids and gases.

5. Aerospace and Automotive

In aerospace and automotive sectors, ferrule fittings are used in hydraulic and pneumatic systems that require maximum reliability.

- Handle extreme temperatures and vibrations.

- Prevent failures in critical systems.

Types of Ferrule Fittings

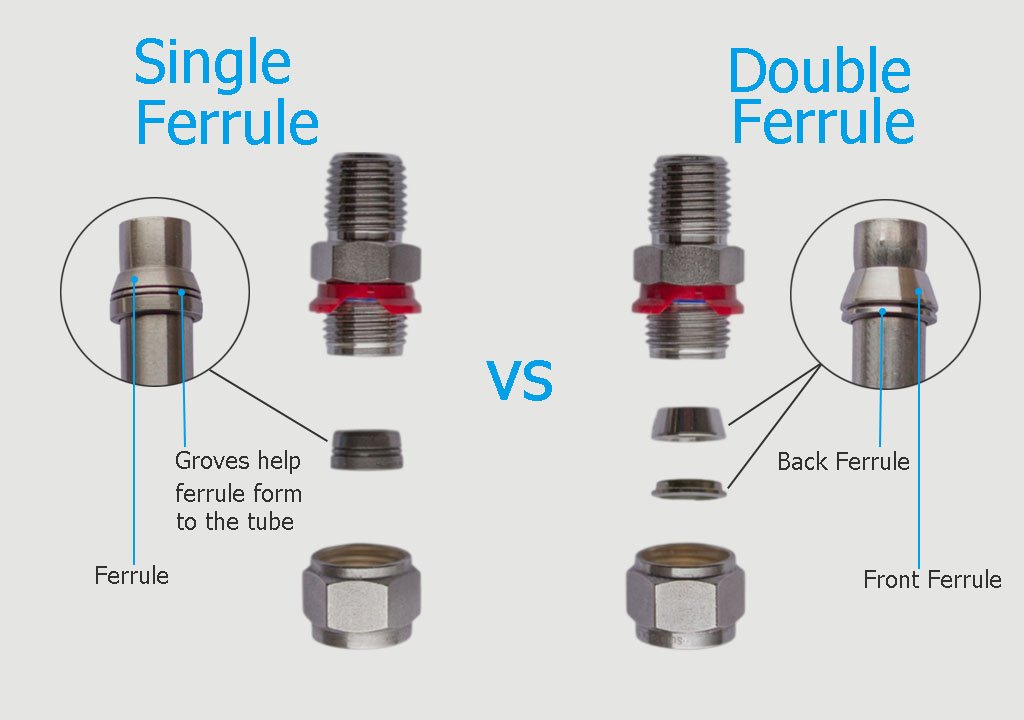

1. Single Ferrule Fittings

- Consist of one ferrule that compresses the tubing.

- Best for moderate pressure applications.

- Cost-effective option for low-stakes environments.

2. Double Ferrule Fittings

- Use two ferrules for a stronger grip and leak-proof seal.

- Excellent for high-pressure systems and vibration-prone environments.

3. Instrumentation Fittings

- Designed for precise control in applications like pressure or temperature measurement.

- Common in laboratories and industrial monitoring systems.

4. Threaded Ferrule Fittings

- Feature threading for extra stability.

- Suitable for environments where tubing connections experience frequent movement.

Materials Used in Ferrule Fittings

The choice of material is critical when selecting a ferrule fitting, as it impacts the fitting’s performance, durability, and resistance to external conditions. Let’s explore the most commonly used materials:

1. Stainless Steel

- Why It’s Used: Stainless steel is the go-to material for ferrule fittings, thanks to its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures.

- Applications: Oil and gas pipelines, chemical processing plants, and food-grade systems.

- Advantages: Durable, hygienic, and resistant to rust even in harsh environments.

2. Brass

- Why It’s Used: Brass is a cost-effective alternative to stainless steel, offering good corrosion resistance and excellent machinability.

- Applications: Low-pressure systems, HVAC systems, and water lines.

- Advantages: Affordable, lightweight, and easier to machine compared to steel.

3. Plastic (e.g., PTFE, PVC)

- Why It’s Used: Plastic ferrule fittings are ideal for applications requiring lightweight and non-conductive materials.

- Applications: Laboratory systems, pharmaceutical setups, and low-pressure fluid transfer.

- Advantages: Chemically inert, lightweight, and easy to install.

4. Nickel Alloys (e.g., Monel)

- Why It’s Used: Nickel alloys like Monel are used in highly corrosive environments, such as marine or offshore industries.

- Applications: Chemical transport, seawater systems, and petrochemical plants.

- Advantages: Exceptional corrosion resistance, even in saltwater or acidic environments.

Common Problems and How to Solve Them

Even with their reliability, ferrule fittings can sometimes present challenges. Consequently, here’s a quick troubleshooting guide to common problems:

1. Leaks After Installation

- Cause: Improper tightening or incorrect ferrule alignment.

- Solution:

- Ensure the tubing is fully inserted into the fitting body.

- Tighten the nut according to the manufacturer’s specifications.

- Check for debris or damage on the ferrule or tubing.

2. Over-Tightening

- Cause: Excessive torque during installation, which can deform the ferrule or tubing.

- Solution:

- Use a torque wrench to avoid over-tightening.

- Follow the “finger-tight plus a quarter-turn” rule.

3. Corrosion Over Time

- Cause: Exposure to harsh chemicals or moisture without proper material selection.

- Solution:

- Use corrosion-resistant materials like stainless steel or Monel.

- Inspect and replace worn-out fittings regularly.

4. Vibration Loosening

- Cause: Constant vibration in systems like HVAC or automotive applications.

- Solution:

- Opt for double ferrule fittings for extra grip.

- Periodically re-tighten the nut to secure the connection.

Industry Standards and Certifications of Ferrule Fittings

They must meet stringent industry standards to ensure safety, quality, and reliability. Accordingly, here’s a rundown of some important certifications:

1. ASME B31.3

- Purpose: Governs the design and testing of piping systems in industries like chemicals and petroleum.

- Relevance: Can withstand high pressures and harsh environments.

2. ISO 9001

- Purpose: Specifies requirements for quality management systems in manufacturing.

- Relevance: Indicates that the fitting was produced under strict quality control.

3. API Standards

- Purpose: Created by the American Petroleum Institute, these standards apply to oil and gas equipment.

- Relevance: Certifies for use in critical oil and gas applications.

4. FDA Compliance

- Purpose: Ensures materials used in food and pharmaceutical fittings meet hygienic standards.

- Relevance: Critical for sterile environments like biopharmaceuticals and food processing.

Comparison with Other Types of Fittings

Here’s how they compare with other popular fitting types:

| Feature | Ferrule Fittings | Threaded Fittings | Welded Fittings | Flared Fittings |

|---|---|---|---|---|

| Installation Ease | Easy | Moderate | Complex | Moderate |

| Leak-Proof | High | Medium | High | High |

| Reusability | Yes | Yes | No | No |

| Pressure Resistance | High | Moderate | Very High | Moderate |

| Maintenance | Easy | Moderate | Difficult | Moderate |

Where to Buy Quality Ferrule Fittings

Looking for reliable ferrule fittings? Here’s a quick guide to help you choose the best suppliers:

Top Brands

- Swagelok: Premium double ferrule fittings.

- Parker Hannifin: Industrial-grade and high-pressure solutions.

Bulk Purchasing Options

For large-scale projects, these suppliers offer discounts and reliable logistics:

- Grainger and McMaster-Carr: Trusted for industrial components with bulk shipping.

- Taske (China): Cost-effective, ISO-compliant, and ideal for international bulk orders.

What to Look For

- Material Compatibility: Match fittings to the application (e.g., stainless steel for corrosive fluids).

- Certifications: Choose fittings that meet ASME, ISO, or FDA standards.

- Reputation: Stick to trusted brands and authorized distributors to avoid counterfeits.

Pro Tip

Taske offers competitive prices, global shipping, and custom fittings, making them an excellent option for cost-effective bulk purchases.

Invest in quality ferrule fittings today to ensure safe and leak-proof connections!

Conclusion

Ferrule fittings are small but mighty components that play a crucial role in creating leak-proof and reliable connections in various industries. Their versatility, durability, and ease of use make them indispensable for anyone working with piping systems. Whether you’re setting up an industrial plant or a simple HVAC system, ferrule fittings are a must-have for ensuring efficiency and safety.

So, the next time you’re piecing together a piping system, don’t overlook the importance of a good ferrule fitting—it just might save you from costly leaks and downtime.

Looking to learn more about piping systems or industrial components? Stay tuned to our blog for more insightful guides!

FAQs

1. What materials are ferrule fittings made of?

Ferrule fittings are commonly made from stainless steel, brass, and sometimes plastic, depending on the application.

2. Can ferrule fittings be reused?

Yes, ferrule fittings can be reused if properly disassembled. However, ensure they are inspected for wear before reinstallation.

3. Are ferrule fittings suitable for high-pressure applications?

Absolutely! Double ferrule fittings, in particular, are designed to handle high-pressure systems.

4. How do I prevent leaks in ferrule fittings?

Follow proper installation procedures, and ensure the tubing and fitting are clean before assembly.

5. What industries commonly use ferrule fittings?

Industries like oil and gas, pharmaceuticals, chemical processing, and HVAC systems rely heavily on ferrule fittings.