Introduction

Ferrule fittings play a crucial role in various industrial applications, ensuring secure and leak-proof connections in piping systems. Used in industries such as oil and gas, pharmaceuticals, and water treatment, these fittings are known for their reliability, durability, and ease of installation. Understanding the different types of ferrule fittings can help businesses and professionals choose the right option for their specific needs.

In this guide, we will explore the various types of ferrule fittings, their benefits, and their applications across different industries.

What Are Ferrule Fittings?

Ferrule fittings are mechanical pipe connectors designed to provide a tight, leak-proof seal between pipes and tubing. They consist of a nut, a body, and one or two ferrules, which compress around the pipe when tightened. This compression mechanism ensures a firm grip without requiring welding or soldering.

Commonly made from stainless steel, brass, or other corrosion-resistant materials, ferrule fittings are widely used in high-pressure applications such as hydraulic and pneumatic systems. Their ability to maintain a secure connection makes them essential in critical industries where leakage prevention is a top priority.

Key Benefits of Using Ferrule Fittings

- Leak-Proof Connections: The compression mechanism ensures a tight seal, reducing the risk of leaks.

- High Durability: Made from robust materials like stainless steel, ferrule fittings can withstand high pressure and extreme conditions.

- Easy Installation: No welding or soldering is required, making installation simple and quick.

- Corrosion Resistance: Materials like stainless steel and brass provide excellent resistance to rust and chemical damage.

- Versatile Applications: Used in a wide range of industries, from plumbing to aerospace, ferrule fittings offer flexibility in various settings.

Types of Ferrule Fittings

Ferrule fittings come in various types, each designed for specific applications and industries. The primary difference lies in their structure, sealing mechanism, and suitability for different pressure levels. Below are the most common types of ferrule fittings:

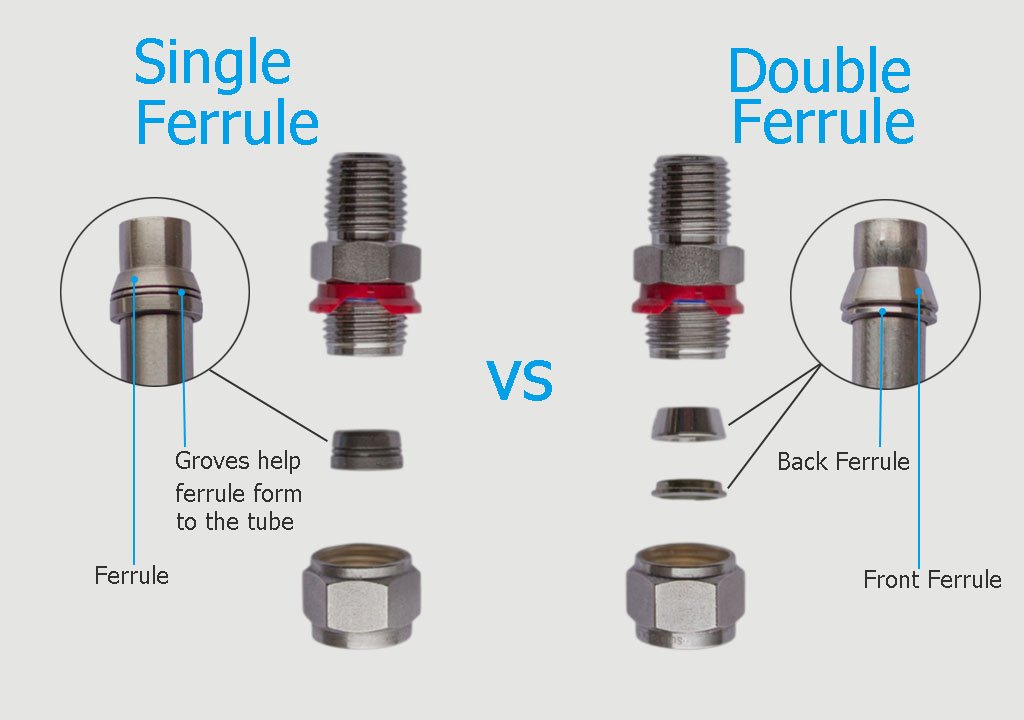

Single Ferrule Fittings

Single ferrule fittings consist of a single metal ring (ferrule) that compresses around the pipe or tubing when the fitting is tightened. These fittings offer a simple yet effective sealing mechanism.

Advantages:

- Easy to install and remove

- Cost-effective compared to double ferrule fittings

- Suitable for low to medium pressure applications

Common Applications: Industrial fluid systems, gas pipelines, and general plumbing connections.

Double Ferrule Fittings

Double ferrule fittings feature two ferrules – a front ferrule and a back ferrule. The front ferrule provides a leak-proof seal, while the back ferrule ensures firm grip and alignment of the tube.

Advantages:

- Enhanced sealing and grip compared to single ferrule fittings

- Prevents tube deformation, making it ideal for high-pressure systems

- Reliable in extreme temperature and vibration conditions

Common Applications: Hydraulic and pneumatic systems, chemical processing, and oil & gas industries.

Compression Ferrule Fittings

Compression ferrule fittings are designed to create a secure connection using a compression nut and ferrule, making them highly popular in household plumbing and gas line installations.

Advantages:

- Simple to install without special tools

- Provides a strong and durable connection

- Suitable for both metal and plastic tubing

Common Applications: Water supply lines, HVAC systems, and residential gas fittings.

Hydraulic Ferrule Fittings

Hydraulic ferrule fittings are specifically designed for high-pressure fluid systems, ensuring leak-proof connections in hydraulic applications. They are made from durable materials such as stainless steel or carbon steel to withstand extreme pressure and temperature conditions.

Advantages:

- Capable of handling high-pressure applications

- Ensures reliable sealing to prevent fluid leaks

- Resistant to corrosion and mechanical wear

Common Applications: Heavy machinery, automotive braking systems, and hydraulic power units.

Pneumatic Ferrule Fittings

Pneumatic ferrule fittings are designed for compressed air and gas systems. They provide a secure and airtight connection to ensure efficient airflow in pneumatic applications.

Advantages:

- Lightweight and easy to install

- Maintains airtight seals for optimal airflow

- Suitable for both industrial and commercial pneumatic systems

Common Applications: Air compressors, industrial automation, and HVAC systems.

Stainless Steel Ferrule Fittings

Stainless steel ferrule fittings are widely used due to their high corrosion resistance and durability. These fittings are ideal for industries where exposure to chemicals and moisture is common.

Advantages:

- Exceptional resistance to rust and chemical corrosion

- High durability, even in extreme conditions

- Ideal for sanitary applications in food and pharmaceutical industries

Common Applications: Food processing plants, pharmaceutical manufacturing, and marine applications.

Brass Ferrule Fittings

Brass ferrule fittings are popular due to their affordability, ease of installation, and resistance to corrosion. They are commonly used in applications where moderate pressure and temperature conditions are expected.

Advantages:

- Cost-effective compared to stainless steel fittings

- Resistant to corrosion and suitable for potable water applications

- Easy to install and maintain

Common Applications: Plumbing systems, fuel lines, and refrigeration units.

Applications of Ferrule Fittings in Various Industries

Ferrule fittings are widely used in multiple industries due to their reliability and ability to provide leak-proof connections. Below are some key industries where these fittings are essential:

- Oil and Gas: Used in high-pressure pipelines and refinery systems.

- Chemical Processing: Ensures secure fluid transfer in corrosive environments.

- Pharmaceuticals: Used in sanitary applications to maintain hygiene and prevent contamination.

- Water Treatment: Essential for connecting pipelines in filtration and desalination plants.

- HVAC Systems: Helps in air conditioning and refrigeration tubing installations.

How to Choose the Right Ferrule Fitting for Your Needs

Selecting the correct ferrule fitting is crucial for ensuring efficiency and safety in your application. Here are key factors to consider:

- Pressure Rating: Choose fittings that can withstand the required pressure levels.

- Material Compatibility: Ensure the fitting material is suitable for the fluid or gas being transported.

- Tube Size: Match the fitting size with the pipe or tubing dimensions.

- Corrosion Resistance: Use stainless steel or brass fittings in environments prone to rust and chemical exposure.

- Industry Standards: Ensure compliance with industry regulations like ASTM, ANSI, or ISO standards.

Installation Guide for Ferrule Fittings

Proper installation of ferrule fittings is essential to ensure leak-proof and durable connections. Follow these steps for a successful installation:

- Prepare the Tubing: Cut the tube to the required length using a tube cutter and remove any burrs.

- Insert the Tube: Slide the ferrule and the nut onto the tube.

- Position the Fitting: Insert the tube into the fitting body until it stops.

- Hand-Tighten the Nut: Secure the nut by hand to hold the ferrule in place.

- Wrench-Tighten: Use a wrench to tighten the nut further according to the manufacturer’s torque specifications.

- Check for Leaks: Test the connection by running fluid or gas through the system.

Following these steps will help ensure a secure and reliable ferrule fitting connection.

Best Practices for Maintaining Ferrule Fittings

Proper maintenance of ferrule fittings extends their lifespan and ensures continued efficiency. Here are some best practices:

- Regular Inspections: Check for signs of wear, corrosion, or loosening.

- Clean the Fittings: Remove dirt, debris, and residue that may affect performance.

- Avoid Over-Tightening: Excessive tightening can damage the ferrule and cause leaks.

- Replace Worn-Out Parts: If a ferrule or nut is damaged, replace it immediately.

- Use Compatible Materials: Ensure that the fitting material is suitable for the operating environment.

Ferrule Fittings vs. Other Types of Pipe Fittings

Ferrule fittings are one of several types of pipe connectors. Here’s how they compare to other fittings:

| Type of Fitting | Advantages | Disadvantages |

|---|---|---|

| Ferrule Fittings | Easy to install, leak-proof, reusable | May not be suitable for extreme high-pressure applications |

| Threaded Fittings | Common and easy to assemble | Prone to leaks over time |

| Welded Fittings | High strength and durability | Requires specialized welding equipment |

| Push-to-Connect Fittings | Quick and tool-free installation | Limited to low-pressure applications |

While ferrule fittings offer convenience and reliability, choosing the right fitting depends on the specific requirements of your system.

Latest Trends and Innovations in Ferrule Fittings

As industries evolve, so do ferrule fittings. Advancements in materials and technology have led to new trends and innovations, including:

- Smart Fittings: Some modern ferrule fittings are equipped with sensors to monitor pressure, temperature, and leakage in real time.

- Advanced Coatings: Corrosion-resistant coatings, such as PTFE and ceramic coatings, enhance the durability of ferrule fittings.

- Eco-Friendly Materials: Manufacturers are shifting towards sustainable and recyclable materials to reduce environmental impact.

- High-Pressure Fittings: New designs can withstand even greater pressure, making them suitable for extreme applications.

These innovations help improve efficiency, safety, and longevity in industrial applications.

Where to Buy High-Quality Ferrule Fittings?

Purchasing high-quality ferrule fittings is crucial for ensuring long-lasting performance. Here are some recommended sources:

- Trusted Manufacturers: Companies like Swagelok, Parker, and DK-Lok are known for high-quality fittings.

- Online Marketplaces: Platforms like Amazon, Alibaba, and eBay offer a variety of ferrule fittings from different brands.

- Local Industrial Suppliers: Visiting a local distributor ensures you get expert recommendations and immediate access to fittings.

- Specialty Stores: Stores that specialize in plumbing, hydraulics, and pneumatics often carry a wide selection of ferrule fittings.

When purchasing, always check for product specifications, material quality, and customer reviews to ensure you are getting the best product for your needs.

Conclusion

Ferrule fittings are essential components in various industries, offering secure and leak-proof connections for fluid and gas systems. With different types available, including single ferrule, double ferrule, hydraulic, and pneumatic fittings, it is important to choose the right one based on pressure rating, material compatibility, and application.

By following best practices for installation and maintenance, you can extend the lifespan of ferrule fittings and ensure reliable performance. As new innovations emerge, ferrule fittings continue to improve in durability, efficiency, and safety, making them a key element in industrial and commercial applications.

Whether you need fittings for oil and gas, pharmaceuticals, or plumbing, selecting high-quality products from reputable manufacturers ensures optimal results.

FAQs

1. What is the difference between single and double ferrule fittings?

Single ferrule fittings use one metal ring to seal and secure the tube, while double ferrule fittings use two rings: one for sealing and one for gripping the tube. Double ferrule fittings provide better grip and prevent tube deformation, making them ideal for high-pressure applications.

2. Can ferrule fittings be reused?

Yes, ferrule fittings can be reused in some cases, but it’s not always recommended. Reusing a ferrule fitting may compromise the seal, leading to potential leaks. For critical applications, it’s best to use a new ferrule and nut.

3. Which industries use ferrule fittings the most?

Ferrule fittings are widely used in industries such as:

- Oil and gas

- Chemical processing

- Pharmaceuticals

- Water treatment

- HVAC systems

- Automotive and aerospace

4. How do I know if my ferrule fitting is leaking?

Signs of a leaking ferrule fitting include visible fluid or gas escape, a drop in system pressure, or unusual noises from the connection point. To check for leaks, perform a pressure test or use soapy water to identify bubbles at the fitting.

5. Are stainless steel ferrule fittings better than brass ones?

It depends on the application. Stainless steel ferrule fittings offer superior corrosion resistance and durability, making them ideal for high-pressure and harsh environments. Brass fittings, on the other hand, are more cost-effective and suitable for moderate pressure applications such as plumbing and gas lines.