1. Introduction

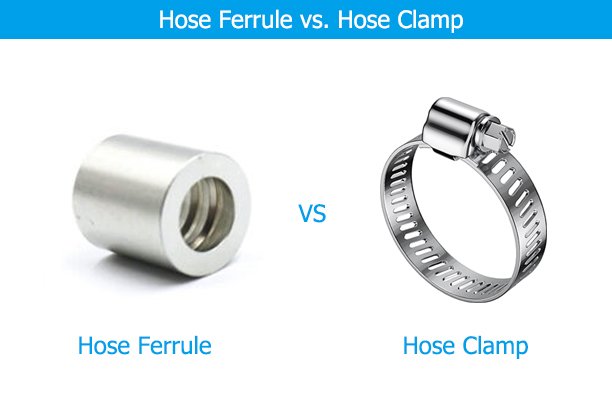

When it comes to securing hoses in various applications, two common options stand out: hose ferrules and hose clamps. Both play a crucial role in ensuring leak-proof, durable connections, but they serve different purposes and are best suited for specific applications.

Choosing between a ferrule and a clamp depends on factors like pressure requirements, material compatibility, and long-term durability. In this article, we’ll compare hose ferrules and clamps, exploring their differences, advantages, and best-use scenarios to help you make an informed decision.

2. Understanding Hose Ferrules

What is a Hose Ferrule?

A hose ferrule is a metal sleeve that is crimped onto a hose to secure it to a fitting. This permanent connection provides a tight seal, ensuring the hose does not leak or detach under pressure.

How Does a Hose Ferrule Work?

Hose ferrules work by being compressed onto the hose using a crimping tool or hydraulic press. This process deforms the ferrule around the hose and fitting, creating a strong, non-removable bond. Ferrules are commonly used in high-pressure hydraulic systems, fuel lines, and industrial applications.

Common Materials for Hose Ferrules

- Stainless Steel: Highly resistant to corrosion and used in heavy-duty applications.

- Brass: Common in fuel and air systems due to its durability and resistance to chemicals.

- Aluminum: Lightweight and suitable for lower-pressure applications.

Advantages of Hose Ferrules

- Extremely Secure: Once crimped, the connection is permanent and highly reliable.

- Leak-Proof: Ideal for hydraulic and pneumatic systems that require airtight seals.

- Durable: Withstands extreme pressures and harsh environments.

3. Understanding Hose Clamps

What is a Hose Clamp?

A hose clamp is a device used to secure a hose onto a fitting, providing an adjustable yet strong grip. Unlike ferrules, hose clamps are removable and reusable, making them a versatile choice for various applications.

Types of Hose Clamps

- Worm Gear Clamps: Feature a screw mechanism for tightening and loosening.

- Spring Clamps: Use spring tension to maintain a firm grip.

- T-Bolt Clamps: Provide high clamping force for heavy-duty applications.

- Ear Clamps: Designed for secure, semi-permanent installations.

Materials and Applications

- Stainless Steel: Corrosion-resistant, ideal for automotive and industrial use.

- Galvanized Steel: Affordable but less resistant to corrosion.

- Plastic: Lightweight and suitable for low-pressure applications.

Benefits of Hose Clamps

- Adjustable: Can be tightened or loosened as needed.

- Easy Installation: No special tools required for most clamps.

- Reusable: Cost-effective solution for temporary or adjustable hose connections.

4. Key Differences Between Hose Ferrules and Hose Clamps

While both hose ferrules and hose clamps serve the purpose of securing a hose connection, they differ significantly in design, installation, and use cases. Below are the primary differences between the two:

Design & Installation

- Hose Ferrule: Requires a crimping tool for installation, creating a permanent bond.

- Hose Clamp: Can be tightened or loosened using a screwdriver or wrench, making it removable and reusable.

Durability & Reliability

- Hose Ferrule: Provides a more secure, leak-proof connection that withstands high pressure.

- Hose Clamp: Reliable but may require periodic retightening, especially in high-vibration environments.

Flexibility & Maintenance

- Hose Ferrule: Once crimped, it cannot be removed or adjusted.

- Hose Clamp: Adjustable and reusable, allowing for easy modifications.

Cost Considerations

- Hose Ferrule: Generally more expensive due to the need for specialized crimping tools.

- Hose Clamp: More budget-friendly and does not require specialized tools.

5. When to Use a Hose Ferrule

Hose ferrules are best suited for applications where a high-pressure, leak-proof, and permanent connection is required. Some ideal use cases include:

- Hydraulic Systems: Used in hydraulic hoses to prevent leaks under high pressure.

- Industrial Applications: Common in fuel lines, air compressors, and pneumatic tools.

- Automotive & Aerospace: Ensures secure fluid transfer in vehicles and aircraft.

- Medical Equipment: Provides a sterile, secure connection in medical-grade tubing.

Safety Benefits

Because ferrules create a permanent bond, they eliminate the risk of loosening, leaking, or bursting, which is crucial in high-risk environments like industrial plants or hydraulic machinery.

6. When to Use a Hose Clamp

Hose clamps are more appropriate for low to medium-pressure applications where adjustability and easy maintenance are needed. Ideal situations include:

- Home & DIY Projects: Used for securing garden hoses, plumbing connections, and air ducts.

- Automotive Repairs: Commonly used in radiator hoses, fuel lines, and vacuum hoses.

- Industrial & Agricultural Use: Suitable for irrigation systems and fluid transport.

- Emergency Fixes: Quick and temporary solution for leaking hoses or broken seals.

Cost-Effective & Easy to Use

Hose clamps provide a simple, adjustable, and cost-effective solution that does not require specialized tools, making them a popular choice for general applications.

7. Pros and Cons Comparison Table

Below is a quick comparison of hose ferrules and hose clamps to help you determine the best choice for your specific needs.

| Feature | Hose Ferrule | Hose Clamp |

|---|---|---|

| Installation | Requires crimping with specialized tools | Easy installation with a screwdriver or wrench |

| Durability | Extremely strong and long-lasting | Durable but may loosen over time |

| Pressure Resistance | Ideal for high-pressure applications | Suitable for low to medium pressure |

| Adjustability | Permanent connection, non-adjustable | Adjustable and reusable |

| Cost | Higher due to required crimping tools | More budget-friendly |

| Common Applications | Hydraulics, industrial, medical, aerospace | Automotive, home, DIY, irrigation |

8. Industry-Specific Recommendations

Different industries have unique requirements for hose connections. Here’s a breakdown of which option is best for each:

Automotive Industry

- Best Choice: Hose clamps

- Why? Adjustability is needed for radiator hoses, fuel lines, and vacuum hoses.

Aerospace Industry

- Best Choice: Hose ferrules

- Why? High-pressure fluid systems require leak-proof and vibration-resistant connections.

Industrial Machinery

- Best Choice: Hose ferrules

- Why? Essential for hydraulic and pneumatic systems where pressure and durability are crucial.

Home & DIY Projects

- Best Choice: Hose clamps

- Why? Easy to install, remove, and adjust for plumbing and garden hoses.

9. Common Mistakes to Avoid When Choosing a Hose Connection

To ensure the best performance and longevity of your hose connections, avoid these common mistakes:

1. Using the Wrong Size

Both ferrules and clamps need to be properly sized to the hose diameter. A mismatch can lead to leaks or failure.

2. Choosing the Wrong Material

Always select materials compatible with the fluid being transported. For example:

- Stainless steel: Ideal for harsh environments.

- Brass: Suitable for fuel and air systems.

- Plastic: Best for low-pressure applications.

3. Over-Tightening or Under-Tightening Clamps

An overtightened clamp can damage the hose, while an under-tightened clamp can cause leaks.

4. Using a Clamp Instead of a Ferrule (or Vice Versa)

For high-pressure applications, a clamp will not provide the required security, and for adjustable connections, a ferrule is not practical.

10. How to Properly Install Hose Ferrules and Clamps

Correct installation is essential for ensuring a secure, leak-free connection. Below is a step-by-step guide for both hose ferrules and hose clamps.

Installing a Hose Ferrule

- Measure & Cut the Hose: Use a sharp hose cutter to ensure a clean, straight cut.

- Slide the Ferrule Onto the Hose: Before inserting the fitting, place the ferrule onto the hose.

- Insert the Fitting: Push the hose fitting into the hose until it is fully seated.

- Crimp the Ferrule: Use a hydraulic crimping tool to compress the ferrule securely around the fitting.

- Inspect the Connection: Ensure there are no visible gaps or deformities.

Installing a Hose Clamp

- Position the Clamp: Slide the hose clamp onto the hose before attaching it to the fitting.

- Attach the Hose to the Fitting: Push the hose fully onto the barb or nipple.

- Tighten the Clamp: Use a screwdriver, wrench, or socket to tighten the clamp evenly.

- Check for Leaks: After installation, apply pressure and inspect for any signs of leaks.

11. Maintenance and Troubleshooting

Regular inspection and maintenance are necessary to extend the lifespan of your hose connections.

Maintenance Tips

- Inspect for Wear & Tear: Check for cracks, corrosion, or loose fittings.

- Replace Worn-Out Clamps or Ferrules: If a connection shows signs of fatigue, replace it immediately.

- Avoid Over-Tightening: Excessive force can damage both the hose and the fitting.

- Use the Right Tools: Ensure you’re using high-quality crimping or tightening tools.

Common Issues & Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Hose is leaking | Clamp is loose or ferrule is improperly crimped | Re-tighten clamp or re-crimp the ferrule |

| Clamp keeps slipping | Hose material is too soft, or the clamp is the wrong size | Use a better-fitting clamp or reinforce with a secondary clamp |

| Ferrule connection fails | Crimping was not performed correctly | Redo crimping with the correct force and tools |

12. Cost Comparison & Long-Term Investment Considerations

Choosing between a hose ferrule and a hose clamp is not just about performance—it’s also about cost-effectiveness. Below is a cost breakdown:

Initial Investment

- Hose Ferrule: Higher initial cost due to required crimping tools.

- Hose Clamp: More affordable upfront, as no special tools are required.

Long-Term Costs

- Hose Ferrule: More durable, reducing the need for replacements.

- Hose Clamp: May require periodic tightening and replacement, increasing maintenance costs over time.

Verdict: If your application demands high-pressure resistance and longevity, a ferrule is a better investment. If flexibility and cost-saving are priorities, clamps are the more economical choice.

Conclusion

Both hose ferrules and hose clamps have their advantages, and the right choice depends on the application.

- For high-pressure, permanent connections, hose ferrules are the best choice.

- For adjustable, cost-effective solutions, hose clamps are ideal.

By understanding the differences in design, durability, cost, and maintenance, you can select the best hose connection method for your specific needs.

Do you have experience using hose ferrules or clamps? Let us know your thoughts in the comments!

FAQs

1. Can I replace a ferrule with a clamp?

In some cases, yes. However, if the application involves high pressure, it is best to stick with a ferrule for a secure, permanent connection.

2. Which option lasts longer?

Hose ferrules generally last longer because they create a permanent, high-strength bond, whereas hose clamps may require periodic tightening and replacement.

3. Are there universal clamps that fit all hoses?

While some adjustable clamps work with multiple hose sizes, it is always best to select a clamp specifically designed for your hose diameter.

4. What is the pressure limit for each option?

- Hose Ferrule: Can withstand extremely high pressures, often over 5,000 PSI, depending on the material.

- Hose Clamp: Typically suited for low to medium pressure applications, up to 300 PSI.

5. How do I choose the right hose connection for my needs?

Consider the pressure rating, installation requirements, durability, and budget. If high pressure and longevity are concerns, go with a ferrule. If flexibility and cost savings are important, choose a hose clamp.