Introduction to Quick Couplers

What is a Quick Coupler?

A quick coupler, also known as a quick hitch or quick connect, is a mechanical device designed to allow fast, secure, and easy connection and disconnection between equipment attachments and host machines. If you’re wondering how to choose a quick coupler, it’s important to understand their role across industries like construction, agriculture, manufacturing, and hydraulic systems. These devices streamline workflow by reducing the time and tools needed to swap attachments like buckets, breakers, or hydraulic hoses.

Quick couplers are typically installed at the end of an excavator arm, skid steer, or hydraulic hose line. Their main job is to ensure secure attachment under high loads or pressures while allowing operators to switch tools without exiting the machine or engaging in lengthy manual processes.

Why Quick Couplers Are Essential in Equipment Operation

Efficiency and safety are two critical pillars in any industrial setting. Quick couplers serve both purposes:

- Time-Saving: Switching tools or attachments manually can take 10–30 minutes. A quick coupler reduces this to a few seconds or minutes.

- Safety: By minimizing manual interaction, quick couplers reduce the risk of hand injuries, pinch points, and improper mounting.

- Versatility: Operators can easily transition between tasks without swapping equipment.

- Cost-Efficiency: Less downtime equals more work completed per hour, which directly impacts profitability.

Whether you’re digging, drilling, or lifting, quick couplers ensure you’re always ready for the next task without missing a beat.

Types of Quick Couplers

Manual Quick Couplers

These are the most basic form of couplers, often requiring the use of hand tools such as pins, levers, or wrenches to connect and disconnect attachments. Although cost-effective and mechanically simple, they can be time-consuming and expose operators to hazards if not used correctly.

Pros:

- Low cost

- Easy to repair

- Fewer failure points

Cons:

- Time-intensive

- Higher risk of injury during attachment changes

- Requires the operator to leave the machine

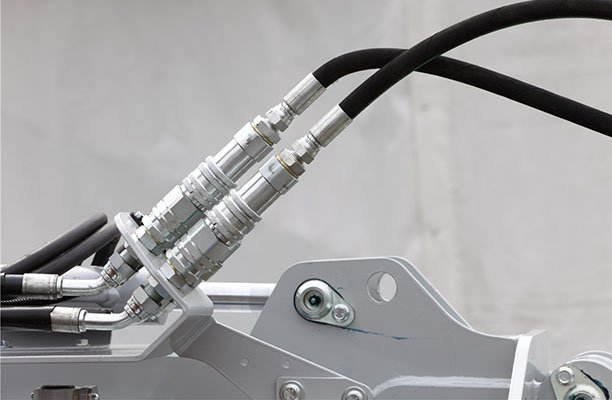

Hydraulic Quick Couplers

Hydraulic couplers use pressurized fluid to engage and disengage the locking mechanism, typically from inside the operator’s cab. As a result, there is no need to physically manipulate the coupler, which in turn significantly reduces risk and enhances efficiency.

Pros:

- Faster switching between attachments

- Safer—operator stays inside the cab

- Can handle high-pressure systems

Cons:

- Higher initial cost

- More components that require maintenance

- Needs a compatible hydraulic control system

Fully Automatic Quick Couplers

This is the most advanced option, ideal for high-frequency tool changes. Fully automatic couplers often integrate multiple safety features, including dual locking systems, visual and audible engagement indicators, and load-holding capabilities.

Pros:

- Ultimate convenience and safety

- Precision-controlled from the cab

- Ideal for 24/7 operations or multi-tasking environments

Cons:

- Most expensive option

- Requires complex calibration

- Potential for electronic or sensor failure

Key Considerations Before Choosing a Quick Coupler

Choosing a quick coupler is not just about grabbing the most popular model—it’s about selecting the one that aligns with your equipment, workflow, and safety standards.

Equipment Compatibility

Start by reviewing your machine’s specifications. The quick coupler must be compatible with:

- Your machine’s weight class and attachment type

- Hydraulic pressure rating

- Mounting interface dimensions

- Control system (manual, hydraulic, or electronic)

Mismatched couplers can lead to performance failures or even structural damage.

Application-Specific Needs

Your industry and use case determine the best type of coupler. For instance:

- Construction and demolition: Requires robust couplers with impact resistance.

- Agriculture: Needs lightweight, corrosion-resistant options.

- Mining or forestry: Prioritizes extreme load-bearing and durability.

Make a checklist of daily attachment types and switching frequency to guide your selection.

Load Capacity and Pressure Ratings

Underestimating your system’s load or pressure requirements can result in equipment failure or safety hazards. Always confirm:

- Max operating pressure (PSI/bar)

- Load limits (kN or tons)

- Hydraulic fluid compatibility

Look for couplers tested and rated beyond your equipment’s maximum workload for added safety.

Material and Build Quality

Steel vs. Aluminum Couplers

The choice of material significantly affects the strength, weight, and corrosion resistance of a quick coupler. Here’s how the two most common materials compare:

| Feature | Steel Couplers | Aluminum Couplers |

|---|---|---|

| Strength | High tensile strength | Moderate strength |

| Weight | Heavier | Lightweight |

| Durability | Extremely durable under harsh conditions | Suitable for lighter-duty tasks |

| Corrosion Resistance | Susceptible without coating | Naturally corrosion-resistant |

| Cost | Generally higher | More affordable for light applications |

Steel couplers are best for heavy-duty applications like construction or mining. Aluminum couplers, on the other hand, are ideal for mobile, agricultural, or indoor environments where weight reduction and corrosion resistance are key.

Corrosion Resistance and Durability

Corrosion is one of the biggest enemies of hydraulic and mechanical systems. Couplers exposed to water, chemicals, or abrasive dust should have protective finishes, such as:

- Nickel or zinc plating (steel)

- Anodization (aluminum)

- Stainless steel (for chemical resistance)

Also, inspect the build for reinforced locking mechanisms, O-ring seal protection, and weld integrity—especially in rough, outdoor, or off-road environments.

Connection and Disconnection Mechanism

Locking Systems

The efficiency and safety of a quick coupler heavily depend on its locking system. These systems are responsible for securing the attachment during operation and releasing it when needed.

There are several types:

- Mechanical lock pins (used in manual systems)

- Hydraulic pins (controlled by cabin switches)

- Dual-lock systems (primary and backup locks for safety)

- Pressure relief valves (in hydraulic hose quick couplers)

A good locking system should be tamper-proof, fail-safe, and resistant to vibration or shock.

Ease of Use in the Field

Field conditions can be unpredictable—mud, snow, dust, and poor lighting make attachment changes more difficult. A user-friendly coupler should:

- Require minimal force to engage/disengage

- Have clear visual markers (e.g., red/green indicators)

- Be operable with gloves or in cold weather

- Offer one-handed or no-hand operation (especially for hose systems)

Time spent struggling with a coupler in the field adds up—ease of use is not just a luxury; it’s a necessity.

Safety Features to Look For

Anti-Disconnect Systems

These systems are designed to prevent accidental disconnection of the attachment, which can lead to catastrophic damage or serious injury. Features include:

- Lock-out valves

- Dual pin mechanisms

- Retaining clips

- Spring-loaded safety latches

Some advanced systems even prevent the machine from operating unless the coupler is fully locked—a critical safety enhancement in environments with multiple operators.

Visual and Audible Lock Indicators

Reliable couplers should provide instant feedback to confirm proper engagement:

- Visual cues like colored markers (green for locked, red for unlocked)

- Audible “clicks” or alarms when the coupler locks

- Sensor alerts in digital control systems (especially in modern excavators)

This ensures that the attachment is secure before any work begins, giving operators peace of mind and reducing liability.

Maintenance and Servicing Requirements

Frequency of Maintenance

The performance and lifespan of a quick coupler largely depend on regular maintenance. The frequency can vary based on usage intensity, environment, and coupler type.

For example:

- Manual couplers may require weekly inspections of pins and alignment.

- Hydraulic systems should be inspected daily for leaks, pressure loss, and seal integrity.

- Automatic couplers need periodic calibration and software diagnostics (if electronically controlled).

For long-term reliability, it’s crucial to follow the manufacturer’s service schedule. Otherwise, neglecting routine care can lead to mechanical failures, oil leaks, or even unsafe operations.

Ease of Replacing Parts

Choose a coupler design that allows fast and tool-free replacement of key components like:

- Seals and O-rings

- Locking pins or bolts

- Hydraulic hoses or fittings

- Visual indicators or alarms

Additionally, opt for brands that maintain a readily available inventory of spare parts, preferably with online ordering or local dealership support. This can drastically reduce downtime during unexpected repairs.

Coupler Standards and Certification

ISO and SAE Standards

Safety and performance are not just about design—they’re also about compliance with global standards. Look for quick couplers that meet:

- ISO 13031 – the international standard for quick couplers on excavators and backhoe loaders, focused on preventing dropped attachments.

- SAE J2513 – applicable in the U.S., ensures secure hydraulic hose coupler systems and connection integrity.

Using certified products means:

- Your equipment is safe to operate.

- You comply with jobsite regulations and insurance requirements.

- You’re protected legally in the event of accidents or breakdowns.

Manufacturer Compliance

Trustworthy manufacturers will prominently state their certifications and testing standards. Look for:

- Third-party test results

- Certificates of conformity

- Detailed technical documentation

Also, reputable brands undergo periodic audits and recertifications, ensuring continuous compliance.

Cost vs. Value Analysis

Initial Investment vs. Long-Term ROI

While it’s tempting to go for the cheapest option, a quick coupler is an investment in efficiency and safety. Here’s what to consider:

- Low-cost models may lack advanced locking systems or durability.

- Premium models often offer faster switching, less maintenance, and longer lifespan—saving thousands over time.

For example, a hydraulic quick coupler that costs $1,200 but saves 30 minutes a day in attachment changes can pay for itself in labor savings within months.

Choosing Quality Over Price

Focus on total cost of ownership, not just the upfront price. Factors to consider include:

- Downtime costs

- Repair frequency

- Fuel or hydraulic inefficiency

- Operator productivity

In industries where every hour counts, investing in a reliable, safe, and high-performing coupler yields better returns than cutting corners.

Brand Reputation and Manufacturer Support

Reviews and User Feedback

One of the smartest ways to evaluate a quick coupler’s real-world performance is by exploring user reviews and industry forums. In particular, operators and mechanics who use these tools daily provide invaluable insights on:

- Long-term durability

- Failure rates under stress

- Ease of installation and use

- Common complaints or product flaws

You can find such reviews on platforms like EquipmentWatch, Reddit’s r/HeavyEquipment, or even YouTube demo videos. However, be sure to focus on how a coupler performs in your specific application, rather than relying solely on general feedback.

Warranty and Service Availability

Moreover, top manufacturers back their products with comprehensive warranties, typically ranging from 12 months to several years depending on the model and usage conditions.

Key things to look for:

- Warranty coverage (Does it include seals, hydraulics, or electronics?)

- Local service centers or authorized repair shops

- Customer support response time

- Availability of technical manuals and online troubleshooting

Ultimately, buying from a reputable brand with a strong global or regional support network results in less hassle during a breakdown—and provides peace of mind knowing that help is readily available.

Interchangeability and Versatility

Multi-Tool Compatibility

In dynamic job environments, being able to switch quickly between buckets, hammers, grapples, and other attachments is crucial. A good coupler should:

- Accept multiple attachment types

- Work with different pin sizes or spacing (within a range)

- Maintain tight, secure connections even with varying loads

Some systems offer variable pin centers or shim kits that allow one coupler to serve multiple attachments, maximizing your fleet’s versatility.

Quick Coupler Adaptors

Above all, always ensure that any adapter you use is load-tested and safety-rated, since poor-quality adapters can compromise the entire system. These adapters:

- Bridge the gap between incompatible tools and couplers

- Reduce the need to buy new attachments

- Allow legacy equipment to work with modern coupler systems

Always ensure that any adapter you use is load-tested and safety-rated, as poor-quality adapters can compromise the entire system.

Environmental and Operational Conditions

Temperature Extremes

Operating in cold climates or extreme heat can affect hydraulic fluid, coupler seals, and metal expansion. If you’re working in temperatures below -20°C or above 40°C:

- Choose couplers with special seals (e.g., Viton or fluorocarbon)

- Use cold-weather rated hydraulic fluids

- Prefer couplers tested in arctic or desert environments

Modern couplers designed for extreme conditions often feature internal heaters or fluid warmers to prevent freezing or gumming up.

Exposure to Dust, Water, and Chemicals

In demanding sectors such as agriculture, mining, or wastewater treatment, couplers are often exposed to abrasive dust, water, salt, or corrosive chemicals. Therefore, in these environments, it’s essential to opt for:

- Sealed couplers with IP-rated enclosures

- Dust caps and protective guards

- Anti-corrosion finishes like epoxy coatings or anodized metals

Some industries may even require chemical-specific couplers, particularly in chemical plants or marine operations.

Popular Quick Coupler Brands and Their Benefits

Top Brands Comparison

When investing in a quick coupler, choosing a trusted brand can make a significant difference in performance, durability, and service support. Here are some of the most respected names in the industry:

| Brand | Strengths |

|---|---|

| CAT (Caterpillar) | Renowned for rugged reliability and seamless integration with CAT machinery. |

| Geith | Offers high-quality couplers with strong locking systems and a reputation for safety. |

| Steelwrist | Leading in innovation with fully automatic couplers and integrated tilt systems. |

| Liebherr | Heavy-duty focus with strong locking force and long service life. |

| Wacker Neuson | Known for compact machinery solutions and durable construction. |

| Taske | Emerging brand with reliable, cost-effective quick couplers known for ease of use, durability, and wide compatibility. |

Niche Use Case Leaders

Taske is gaining attention in both local and international markets due to its affordable price point, efficient locking designs, and support for a wide variety of attachment types, making it ideal for mixed fleets or mid-size operations.

Niche Use Case Leaders

Some manufacturers specialize in unique applications:

- OilQuick – Designed for ultra-fast hydraulic attachment changes.

- Engcon – Known for tiltrotators with coupler integration.

- JRB – Excellent for wheel loaders and large equipment.

- Kinshofer – High durability for demolition and material handling.

Whether you’re prioritizing advanced automation, robust strength, or adaptability across brands, Taske and its competitors offer a wide range of solutions tailored to different industry needs.

Installation Tips and Professional Advice

DIY vs. Expert Installation

Quick couplers may seem plug-and-play, but improper installation can lead to catastrophic failure. Here’s how to decide who should handle it:

- DIY Installation: Acceptable for manual couplers or experienced operators/mechanics with access to proper tools and manuals.

- Professional Installation: Recommended for hydraulic or fully automatic systems, especially those integrated with electronics or safety locks.

Professional installation ensures:

- Proper hydraulic pressure calibration

- Secure welds or bolt alignments

- Correct sensor integration

Skipping this step may void the warranty, so always check the manufacturer’s terms.

Calibration and Testing

After installation, conduct field testing under operational conditions:

- Cycle the attachment several times to check for engagement and disengagement issues.

- Inspect hydraulic lines for leaks.

- Ensure indicator lights or alarms work properly.

Some systems allow fine-tuning via onboard software—if so, consult the digital manual or technician for optimal settings.

Troubleshooting Common Quick Coupler Issues

Leakages and Connection Failures

Leakages are often due to:

- Worn seals or O-rings

- Improper mating surfaces

- Over-tightened or under-tightened fittings

Connection failures, especially in hydraulic couplers, can result from:

- Contaminants in the hydraulic fluid

- Damaged locking pins

- Improper line pressure

Solution:

- Clean all mating surfaces

- Replace damaged seals

- Ensure pressure is within the manufacturer’s specified range

Wear and Tear Symptoms

Even the best couplers degrade over time. Common signs of wear include:

- Loose attachments

- Slow or incomplete locking

- Corrosion around pins or connectors

- Inconsistent hydraulic flow

To extend service life, preventative maintenance—such as weekly inspections, lubrication, and seal replacement—is highly effective. Furthermore, don’t ignore small issues, as they often escalate into costly failures.

Conclusion

Choosing the right quick coupler is not a one-size-fits-all decision. It requires a clear understanding of:

- Your machine’s capabilities

- The nature of your applications

- Safety and regulatory requirements

- Desired efficiency and long-term value

Investing in a well-built, properly rated, and industry-certified quick coupler can transform your workflow by:

- Minimizing downtime

- Enhancing safety

- Improving operator productivity

- Extending the life of your equipment

Whether you’re managing a construction site, running a farm, or working in heavy industry, the right coupler is a critical link between your machine and its purpose.

If in doubt, consult with a trusted manufacturer or equipment dealer. The added expertise will help ensure you maximize ROI and maintain compliance with safety standards.

FAQs

1. How can I find the right quick coupler for my machine?

Check your machine’s model and size, then match it with the coupler’s size and type. Look at things like pin size, attachment type, and hydraulic pressure. If you’re unsure, ask your equipment dealer for help.

2. Which is better: manual or hydraulic quick coupler?

Manual couplers are cheaper but take more time and effort to use. Hydraulic couplers are faster and easier—you don’t have to leave the cab—but they cost more. Choose based on how often you change tools and your budget.

3. Can I use one quick coupler on different machines?

Sometimes. Some couplers work with many machines, but you might need an adapter. Always check if the coupler fits your machine and attachments.

4. Do quick couplers need maintenance?

Yes! Check for leaks, worn-out seals, and loose parts. Clean and grease the moving parts often. Doing this helps your coupler last longer and work safely.

5. Are quick couplers safe for heavy work?

Yes, if they’re made for the job. Make sure the coupler has safety locks and is strong enough for your machine. Look for models that meet ISO or other safety standards.

6. How long will a quick coupler last?

With regular use and care, a quick coupler can last several years. Manual types last longer with fewer parts to fix. Hydraulic or automatic couplers may need repairs sooner but save time.