National Pipe Taper (NPT) fittings are vital in plumbing and industrial systems. Their unique design ensures leak-free connections in applications involving liquids, gases, and steam. Misidentifying NPT fittings can lead to costly errors, compatibility issues, and potential safety hazards. This guide will help you accurately identify NPT fittings to ensure efficient operation and prevent mistakes.

What Are NPT Fittings?

NPT (National Pipe Taper) fittings are a U.S. standard for tapered threads that have been a cornerstone of plumbing and industrial applications for over a century. These fittings play a critical role in sealing pipe connections for the transfer of fluids and gases in various systems. They are designed to provide a secure and leak-resistant connection, making them essential for both low-pressure and high-pressure environments. Understanding how NPT fittings function, their material compatibility, and their design is key to ensuring optimal performance in any application.

Material and Pressure Compatibility

NPT fittings are available in a wide range of materials, each suited to specific operating conditions. Choosing the right material is essential to ensure durability, resistance to environmental factors, and compatibility with the substances being transported.

- Iron and Brass:

These materials are typically used in low-pressure systems, such as residential plumbing or irrigation setups. Brass is particularly favored for its resistance to corrosion and its ability to handle mild water-based or gaseous applications. Iron fittings, while robust, are best suited for non-corrosive environments. - Carbon Steel and Stainless Steel:

These materials are essential for high-pressure applications found in industrial or chemical processing systems. Carbon steel offers excellent strength and is commonly used in environments where durability is a priority. Stainless steel provides superior resistance to corrosion, making it ideal for transporting corrosive fluids or gases, especially in marine, food processing, or pharmaceutical industries.

In selecting the material, factors like operating pressure, temperature, and the nature of the fluid or gas being transported should always be considered. This ensures long-term reliability and safety in the system.

Nominal Pipe Size Identification

Identifying the nominal pipe size (NPS) of an NPT fitting is a straightforward process but requires precision to avoid mismatched connections. The nominal pipe size does not directly correlate to the physical measurement of the thread diameter, leading to potential confusion for those unfamiliar with the standard.

- To determine the NPS, measure the thread diameter of the fitting using a caliper or ruler.

- Subtract 1/4″ (0.25 inches) from the measurement to calculate the nominal size.

For example, if the thread diameter measures 1.25 inches, the nominal pipe size would be 1 inch. This standardized sizing system simplifies the selection of compatible fittings, ensuring proper connection with pipes or other components in the system.

It is important to note that NPT fittings follow their own sizing conventions, which differ from metric or other regional standards like BSP (British Standard Pipe). This makes accurate identification crucial when working in systems with diverse threading standards.

Step-by-Step Guide to Identifying NPT Fittings

Accurately identifying NPT (National Pipe Taper) fittings is crucial for ensuring compatibility and creating secure, leak-resistant connections. This step-by-step guide will walk you through the process, providing practical tips and techniques for precise identification.

1. Inspect Visual Features

The first step in identifying NPT fittings is a close visual inspection. Understanding what to look for in the design and threading can help you differentiate NPT fittings from other standards, such as BSP or ISO threads.

- Tapered Design:

Look for a noticeable taper in the threads, where the diameter decreases slightly as the threads extend along the fitting. This taper is a hallmark of NPT fittings and distinguishes them from parallel-threaded fittings like BSP. - Thread Profile:

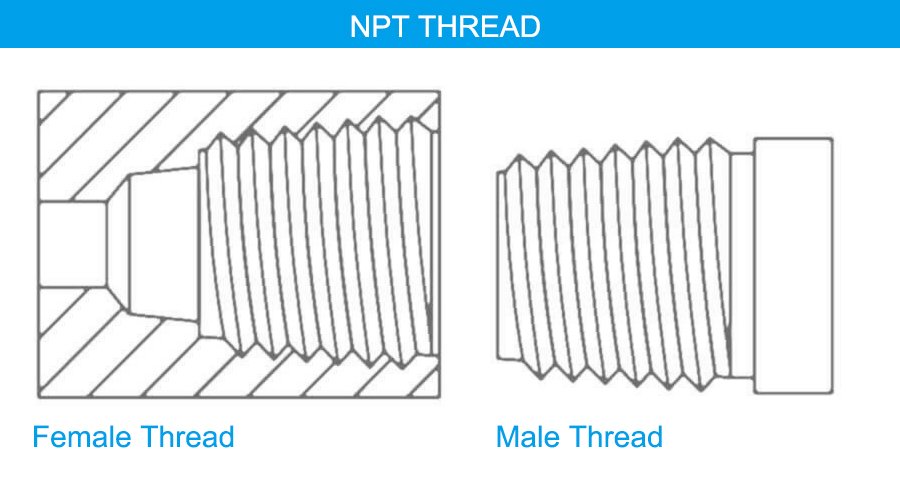

Examine the angle and spacing of the threads. NPT fittings have a 60° thread angle, which gives them a distinct appearance compared to BSP threads, which have a 55° angle. - Male and Female Threads:

Identify whether the fitting is male (external threads) or female (internal threads). Ensure that the thread pattern matches the corresponding fitting.

Pro Tip: Use a magnifying glass or a thread comparator for a clearer view of the threading details, especially on smaller fittings.

2. Measure the Threads

Measuring the threads provides concrete data to confirm whether a fitting is NPT. Use precision tools such as calipers and rulers to obtain accurate measurements.

- Thread Diameter:

Use a caliper to measure the outside diameter (OD) of the male threads or the inside diameter (ID) of the female threads. Take measurements at multiple points along the threads to identify whether the diameter decreases (indicating a taper). - Thread Pitch:

Determine the distance between adjacent threads by measuring from the crest of one thread to the next. Alternatively, you can use a thread gauge for more precise pitch measurements. - Length of Thread Engagement:

Measure the length of the threads from the first to the last visible thread. This helps distinguish NPT fittings from straight-threaded connections, as tapered threads typically have a shorter thread length.

Pro Tip: Record all measurements and compare them to a standard NPT thread chart to ensure consistency with NPT specifications.

3. Confirm with a Thread Gauge

Using a thread gauge is one of the most reliable ways to identify NPT fittings. This tool allows you to verify the pitch and angle of the threads with precision.

- Matching the Threads:

Align the thread gauge with the threads of the fitting. Ensure the gauge fits snugly along the entire length of the threads without gaps. - Checking the Angle:

Confirm that the thread angle matches the standard 60° angle of NPT threads. If the gauge doesn’t align perfectly, the fitting may belong to a different standard, such as BSP or ISO. - Comparing the Taper:

For tapered threads, check that the gauge maintains contact across the taper. If the gauge slides off or leaves gaps, the fitting may not be NPT.

Pro Tip: Keep a set of standard thread gauges for NPT, BSP, and other common standards to make side-by-side comparisons easier.

4. Check for Tapered Ends

One of the defining features of NPT fittings is their tapered ends. This feature is critical to the fitting’s sealing mechanism and distinguishes it from straight-threaded fittings.

- Visual Inspection:

Look closely at the male fitting’s threads. The diameter should visibly reduce as the threads extend toward the end of the fitting. - Measure the Taper Angle:

Use a protractor or a taper gauge to measure the taper angle, which should align with the NPT standard taper rate of 1:16 (3/4 inch per foot of thread length). - Testing the Fit:

Insert the male fitting into a corresponding female fitting. If it tightens securely after a few turns, it confirms the presence of tapered threads. Straight threads, by contrast, will not create a tight seal and may continue turning without resistance.

Pro Tip: If the taper is difficult to detect visually, use a caliper to measure the diameter at both ends of the threads and compare the measurements.

5. Compare to a Thread Chart

Once you’ve gathered your measurements, compare them against an NPT thread chart. These charts provide detailed specifications for NPT fittings, including thread size, pitch, and taper dimensions.

- Match Thread Dimensions:

Locate the size on the chart that corresponds to your measurements. Ensure the pitch and diameter align with the NPT standard for the fitting size. - Verify Taper Details:

Confirm that the measured taper matches the standard taper ratio of 1:16.

Pro Tip: Keep an updated thread chart readily available when working with fittings, especially in environments with mixed thread types.

6. Test the Fit

The final step is a practical test to confirm the fitting’s identity and compatibility. Assemble the fitting with a known NPT counterpart to check for proper fit and sealing.

- Thread Engagement:

Screw the male fitting into a female fitting of the same nominal size. Proper NPT fittings should engage smoothly and tighten securely after 2–3 turns. - Leak Test:

For fittings in active use, perform a leak test by pressurizing the system with air or water. No leaks should occur if the connection is properly tightened.

Pro Tip: Apply thread sealant, such as Teflon tape, to improve the seal during the test. This can help ensure the fitting’s identity and performance.

Applications of NPT Fittings

NPT fittings are used in a variety of settings, from residential plumbing to complex industrial systems. Their ability to create leak-proof connections makes them indispensable in scenarios where safety and efficiency are critical.

- Residential Plumbing:

NPT fittings are commonly used in homes for water and gas lines. They ensure that connections remain leak-free, which is essential for safety and energy efficiency. For example, NPT connections are often found in natural gas piping systems and water heaters. - Industrial Systems:

In industrial applications, NPT fittings are frequently used in pipelines that transport high-pressure liquids, gases, or steam. Industries such as oil and gas, chemical processing, and manufacturing rely on these fittings for their durability and ability to maintain tight seals under extreme conditions. - HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems also use NPT fittings to manage the flow of refrigerants and other gases. The tapered design ensures that the fittings remain secure even in systems subject to constant pressure changes. - Automotive and Aerospace:

In automotive and aerospace industries, NPT fittings are used in fuel lines, hydraulic systems, and other high-performance applications. The reliability of the seal is crucial for maintaining system integrity in these high-stakes environments.

Disadvantages of NPT Fittings

While NPT fittings are versatile, they have some limitations:

- Over-tightening may cause port expansion or cracking.

- Proper orientation of shaped connectors can be challenging.

- Thread lubricants can introduce system contamination.

- Not recommended for extremely high-pressure systems.

- Performance decreases with reassembly, especially for larger sizes, increasing the risk of leaks.

Advantages of NPT Fittings

Despite their drawbacks, NPT fittings offer several benefits:

- Readily available in various sizes, shapes, combinations, and materials.

- Easy to use without the need for additional seals, O-rings, or tube flaring.

- Popular and well-known, making replacements and compatibility straightforward.

NPTF vs NPSM Thread

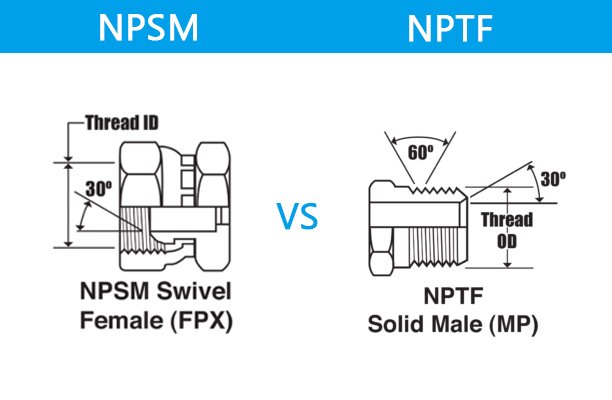

NPTF (National Pipe Taper Fuel) threads differ slightly from traditional NPT threads. While NPT threads leave a small clearance between the thread crests and roots, NPTF threads eliminate this gap. The thread root deforms to create a dry, leak-proof seal, often without requiring additional sealants. However, lubricants are still used during assembly to reduce friction.

NPSM (National Pipe Straight Mechanical) threads are another common variation. Unlike NPT or NPTF, NPSM threads are non-tapered. The female fitting includes a straight thread and a 30° inverted chamfer that forms a mechanical seal with the male connector. Properly chamfered NPTF male threads can also fit NPSM female threads, offering excellent versatility for fluid power systems.

Compatibility with Other Thread Styles

NPT threads are often mistaken for similar styles like BSP or certain DIN standards. While they may look alike, differences in thread pitch, angle, and dimensions make them incompatible. Always ensure the correct thread type is used to maintain a safe, leak-free connection.

Conclusion

Identifying NPT fittings requires careful inspection, accurate measurement, and a solid understanding of thread characteristics. With this guide, you can confidently distinguish NPT fittings, ensuring compatibility and leak-free connections in your systems.

FAQs

1. Can NPT fittings be reused?

Yes, NPT fittings can be reused, but their sealing performance decreases with each reassembly. This is due to thread deformation that occurs when the fitting is tightened. For critical applications, it’s recommended to use new fittings or apply fresh thread sealant during reassembly.

2. What’s the difference between NPT and BSP threads?

NPT threads are tapered and have a 60° thread angle, while BSP threads may be tapered (BSPT) or straight (BSPP) with a 55° thread angle. These differences make them incompatible, so care must be taken to ensure the correct fitting type is used.

3. How can I ensure a leak-proof NPT connection?

For a reliable seal, always:

- Use thread sealant tape or liquid thread sealant.

- Tighten the fitting to the manufacturer’s recommended torque specifications.

- Inspect the fitting for damage or wear before installation.

4. Can I mix NPT with NPTF or NPSM threads?

NPT and NPTF threads are compatible, but the seal quality differs. NPT requires a sealant, while NPTF is designed for a dry seal. NPTF can also connect with NPSM threads, as NPSM uses a straight mechanical seal that aligns with tapered NPTF threads.

5. Are NPT fittings suitable for high-pressure systems?

NPT fittings can handle moderate to high pressure but are not recommended for extremely high-pressure systems due to potential leak paths. For high-pressure applications, fittings like O-ring face seal (ORFS) or compression fittings are better alternatives.

6. How do I identify the correct NPT fitting size?

To identify the size of an NPT fitting:

- Measure the thread diameter with a caliper.

- Use a thread pitch gauge to find the threads per inch (TPI).

- Match these measurements to an NPT size chart for accurate identification.