Introduction

When it comes to creating secure and leak-free hose connections, few components are as crucial as hose barb fittings. Whether you’re working on automotive repairs, industrial systems, or home projects, getting the correct hose barb size is essential. Misfitting parts can cause leaks, system inefficiencies, or even complete failure. That’s why understanding how to measure hose barb fittings properly is vital for both beginners and seasoned technicians.

In this comprehensive guide, you’ll learn the step-by-step process of measuring hose barb fittings, understand different fitting types, and discover pro tips to ensure every connection is tight, reliable, and long-lasting.

Understanding Hose Barb Fittings

What is a Hose Barb Fitting?

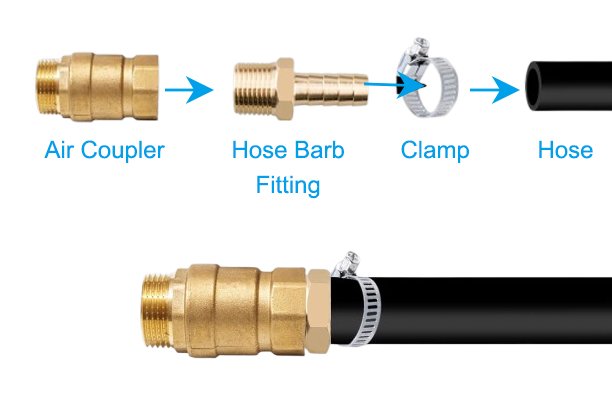

A hose barb fitting is a small yet vital connector designed to join a hose to another component such as a pipe, pump, valve, or another hose. The key characteristic of a barb fitting is its series of ridges or barbs that grip the inside of a flexible hose when pushed in. This design prevents the hose from slipping off under pressure, ensuring a secure and leak-resistant connection.

Types of Hose Barb Fittings

- Straight Barb Fittings: The most common type used for simple, inline hose connections.

- Elbow Barb Fittings: Designed for 90-degree turns to navigate tight spaces.

- Y and T Barb Fittings: Used to split or merge hose flow into multiple directions.

- Reducer Barb Fittings: Connect hoses of different diameters.

Common Materials for Hose Barbs

- Brass – durable and corrosion-resistant, common in automotive and industrial applications.

- Plastic (Nylon, Polypropylene) – lightweight, affordable, and ideal for low-pressure systems.

- Stainless Steel – excellent for high-pressure or corrosive environments.

- Aluminum – used where weight savings are important, though less common.

Hose Barb Sizing Basics

What Does Hose Barb Size Mean?

Hose barb size refers to the outer diameter (OD) of the barb section itself. This is the part that fits inside the hose and creates the seal. Choosing the correct size ensures that the hose fits snugly without being too tight or too loose.

Difference Between Hose Barb Size and Hose ID

A common source of confusion is mixing up hose barb size with the hose’s internal diameter (ID). The hose ID is the inner measurement of the hose, and ideally, it should match or be slightly smaller than the barb OD to create a secure connection. For example, a hose with a 1/2-inch ID should typically fit a 1/2-inch barb fitting.

Hose Barb Size vs. NPT (National Pipe Thread) Size

Another confusion arises when comparing hose barb sizes to pipe thread sizes (NPT). They are not the same. The NPT size refers to the threaded portion of the fitting, not the barb. Always confirm both the barb and thread sizes when selecting fittings.

Tools You Need to Measure Hose Barb Fittings

Before you start measuring, having the right tools on hand will ensure accuracy and save time. Here are the essential tools commonly used for hose barb fitting measurements:

Caliper

A caliper is the most precise tool for measuring the outer diameter (OD) of the barb. Digital calipers are recommended for their ease of use and precise readings, but manual calipers will also work effectively.

Measuring Tape

A flexible measuring tape can be used in situations where calipers might not fit, especially for larger barbs or irregular shapes. While less precise than calipers, it can still give a good approximation.

Hose Sizing Gauge

Hose sizing gauges are specifically designed to measure both the internal diameter (ID) of hoses and the external diameter of fittings. These gauges are common in professional workshops and are great for quick reference.

Digital vs. Manual Tools

Digital tools offer quick and highly accurate measurements, but manual tools are often more affordable and durable. Choose based on your budget and measurement precision needs.

Step-by-Step Guide: How to Measure Hose Barb Fittings

Follow this simple step-by-step guide to measure your hose barb fittings accurately:

Step 1: Inspect the Fitting

Check the fitting for damage, corrosion, or irregularities. Worn-out fittings may give misleading measurements, so it’s best to measure a new or lightly used fitting if possible.

Step 2: Measure the Largest Outside Diameter of the Barb

Use your caliper or measuring tape to measure the largest outside diameter of the barb (the ridged part that enters the hose). This measurement is your barb size. Record the measurement in inches or millimeters depending on your region or industry standard.

Step 3: Measure the Hose ID

Measure the internal diameter (ID) of the hose you will use. It should closely match or be slightly smaller than the barb OD to ensure a tight fit. A slightly undersized hose will stretch over the barb for a secure grip.

Step 4: Confirm with a Hose Size Chart

Always cross-check your measurements with a reliable hose barb size chart (covered in the next section) to ensure accuracy and compatibility with industry standards.

How to Use a Hose Barb Size Chart Properly

Using a hose barb size chart is essential for confirming your measurements and selecting the correct fitting. Here’s how to make the most of it:

Understanding the Chart

Hose barb size charts typically display barb OD, corresponding hose ID, and sometimes recommended hose wall thickness. They help bridge the gap between your measurement and the actual fitting selection.

Cross-Referencing Your Measurements

Locate your measured barb OD on the chart. Find the recommended hose ID that pairs with your fitting. This ensures the hose will fit securely without gaps or excessive stretching.

Adjusting for Tolerance and Manufacturer Differences

Keep in mind that slight variances may exist between manufacturers. Always check the technical specifications from the specific brand or supplier you are using to account for small deviations in sizing.

Common Mistakes to Avoid

Even experienced technicians sometimes make errors when measuring hose barb fittings. Avoid these common pitfalls to ensure a secure and effective hose connection:

Assuming NPT Size Equals Hose Barb Size

One of the most frequent mistakes is assuming that the NPT (National Pipe Thread) size is the same as the barb size. In reality, the NPT size refers to the thread portion and not the barb. Always measure the barb directly to get the correct size.

Overlooking Hose Wall Thickness

Focusing solely on the hose’s internal diameter (ID) without considering the wall thickness can lead to a poor fit. A thick-walled hose may not stretch enough to fit over the barb even if the ID matches.

Ignoring Manufacturing Tolerances

Different manufacturers may have slight deviations in sizing. For example, a 1/2-inch barb from one brand may vary slightly from another. Always check the supplier’s technical datasheet or verify with a sizing chart.

Pro Tips for Precise Fitting

Following these expert tips will help you achieve a perfect fit every time, whether you’re working on a professional project or a DIY task:

Measuring Used or Worn Fittings

Used fittings may have worn barbs, which can result in inaccurate measurements. If possible, always measure new or minimally used fittings for reliable sizing.

Measuring Without Disassembly

If the hose system is already assembled, you may still measure by carefully measuring the external fitting and estimating the barb size based on common standards. However, this method may introduce slight inaccuracies and should be confirmed with reference charts when possible.

Seeking Professional Advice When in Doubt

For critical applications—such as high-pressure, hazardous, or industrial systems—consult a specialist. Incorrect sizing could lead to system failure, leaks, or safety hazards. Many suppliers provide technical support to help you choose the correct fitting.

Applications of Hose Barb Fittings

Hose barb fittings are versatile and widely used across many industries. Here are some of the most common applications:

Automotive

Used in fuel lines, coolant systems, vacuum hoses, and hydraulic circuits where secure and leak-proof connections are critical.

Industrial Equipment

Applied in pneumatic and hydraulic systems, chemical transport, and factory machinery for transferring air, fluids, and gases.

Home and Garden Systems

Ideal for irrigation systems, garden hose connections, and household plumbing, making installation simple and maintenance-friendly.

Medical and Laboratory Equipment

Used in various lab setups, medical devices, and diagnostic equipment where clean, reliable, and secure fluid connections are essential.

When and Why to Replace Hose Barb Fittings

Like any mechanical component, hose barb fittings are subject to wear and tear. Knowing when to replace them is essential for system reliability and safety.

Signs of Wear and Tear

- Visible corrosion: Particularly on metal fittings exposed to moisture or chemicals.

- Damaged barbs: Worn or flattened barbs reduce grip, leading to leaks.

- Cracks or deformation: More common in plastic fittings under pressure or UV exposure.

Impact of Improper Sizing on System Performance

Using a poorly sized fitting, even if it looks acceptable, can cause serious issues, including fluid leakage, reduced pressure, and system failure. In pressurized systems, this could also pose safety risks.

Recommended Replacement Intervals

While there is no universal rule, many professionals recommend replacing hose barb fittings during scheduled maintenance, when upgrading system components, or if signs of damage are present. High-pressure and critical applications may require more frequent inspections and replacements.

Alternative Hose Fitting Types

While hose barb fittings are common, they are not the only option. Depending on your system’s requirements, you may consider other types of hose fittings:

Compression Fittings

These fittings create a seal by compressing a ferrule against the hose or tube. They are widely used for applications requiring a strong mechanical seal without relying on hose elasticity.

Push-to-Connect Fittings

Push-to-connect fittings allow for quick and easy hose connections without clamps or special tools. They are commonly used in pneumatic and low-pressure systems where ease of assembly is a priority.

Quick-Connect Couplers

These fittings are designed for fast and convenient connection and disconnection of hoses. They are used in hydraulic, air, and water systems where frequent changes are needed without compromising on sealing.

Hose Barb Fittings Maintenance Tips

Proper maintenance can significantly extend the life of your hose barb fittings and ensure your system operates smoothly:

Cleaning and Inspection

Regularly inspect your fittings for signs of wear, corrosion, or contamination. Clean the fittings to remove debris, mineral deposits, or residues that could compromise the seal.

Lubrication Techniques

Using a suitable lubricant during installation (e.g., silicone-based or compatible assembly lube) helps the hose slide over the barb more easily and reduces the risk of damage to both the fitting and the hose.

Storage and Handling Best Practices

Store unused fittings in a dry, clean environment away from UV exposure. Avoid dropping or denting metal fittings, as small deformities can lead to leaks.

Conclusion

Measuring hose barb fittings correctly is vital to achieving leak-free, secure connections across a wide range of applications, from automotive and industrial systems to home projects. By understanding how to measure barb sizes properly, selecting the right tools, and following industry best practices, you can ensure long-lasting and reliable hose assemblies.

Remember, always double-check your measurements with a hose barb sizing chart and don’t hesitate to consult a professional when dealing with critical or high-pressure systems. Proper sizing enhances not only the performance but also the safety of your entire system.

FAQs

How do I measure without removing the fitting?

If the system is already assembled, measure the exposed barb diameter carefully using a caliper or measuring tape. While this method may not be as accurate, it often provides enough information for a close match. Confirm your estimates with a sizing chart if possible.

Can I use a slightly bigger or smaller barb?

It is generally not recommended. A slightly smaller barb may result in a loose fit and leaks, while a slightly larger barb may damage the hose during installation or cause stress fractures. Always aim for a properly matched size to ensure safety and performance.

Does material affect sizing?

No, the sizing standard (OD of the barb) remains the same regardless of material. However, different materials may behave differently under pressure and wear conditions. For example, plastic barbs may deform more easily under high temperatures compared to metal ones.

What is the tolerance range when fitting hoses?

In most cases, hose barb fittings allow for a slight variation (usually ±0.010 inches or ±0.25 mm). However, this varies by manufacturer. Always check the technical specifications provided by the fitting supplier.

Are hose barb fittings suitable for high-pressure applications?

Hose barb fittings are typically used in low to moderate pressure systems. For high-pressure applications, consider fittings designed specifically for such environments, such as hydraulic compression or crimp fittings.