Introduction to Hydraulic Control Valves

Hydraulic systems are the backbone of many industries, from construction and mining to agriculture and manufacturing. These systems rely on precise fluid control to deliver power efficiently, and at the center of this process lies the hydraulic control valve. However, when problems arise, hydraulic control valve failure can disrupt operations, reduce efficiency, and even cause costly downtime.

When a valve begins to fail, it disrupts the entire hydraulic circuit. This can lead to erratic machine movements, reduced productivity, and even complete system shutdowns. The cost of ignoring valve issues can be enormous—not just in terms of repairs, but also lost time and potential safety hazards.

This article will guide you through the warning signs of hydraulic control valve failure, root causes, diagnostic techniques, and effective solutions to keep your machinery running smoothly.

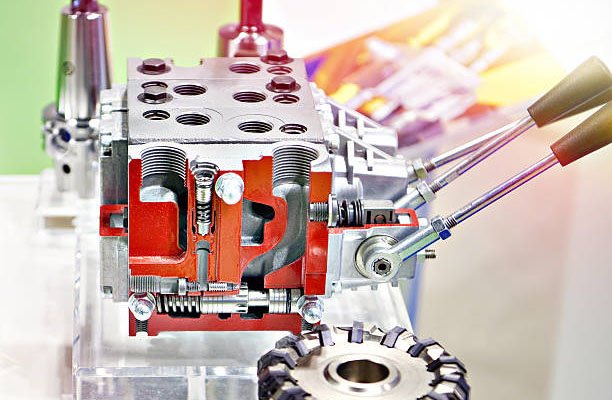

What is a Hydraulic Control Valve?

A hydraulic control valve is a precision-engineered device designed to regulate the flow and pressure of hydraulic fluid. In simple terms, it decides where, when, and how much hydraulic power should be delivered to various components of the system.

Here are the main functions of a hydraulic control valve:

- Directing Fluid Flow: Determines the path hydraulic oil takes to reach actuators, motors, or cylinders.

- Regulating Pressure: Prevents system overload by maintaining proper pressure levels.

- Controlling Speed & Force: Adjusts how quickly and forcefully actuators move.

Without this valve, even the most powerful hydraulic pump would be useless, as there would be no way to control the energy being generated.

Types of Hydraulic Control Valves include:

- Directional Control Valves (DCVs) – Decide the path of fluid flow.

- Pressure Control Valves – Maintain safe pressure levels.

- Flow Control Valves – Manage speed of actuators.

Each valve plays a unique role, but all are equally critical to efficient system performance.

Importance of Hydraulic Control Valves in Machinery

Hydraulic control valves are often referred to as the “traffic cops” of hydraulic systems. Just like traffic signals ensure smooth vehicle movement on busy roads, control valves manage the safe and efficient flow of hydraulic oil.

Key Reasons They’re So Important:

- Safety – Valves prevent over-pressurization, which can otherwise lead to catastrophic failures.

- Efficiency – Properly functioning valves ensure minimal energy loss, lowering fuel and power costs.

- Precision – They allow operators to make fine adjustments in machinery movements.

- Durability – By preventing stress overload, valves extend the lifespan of pumps, cylinders, and other hydraulic components.

Imagine a bulldozer lifting heavy soil: without a properly functioning control valve, the lift arm might jerk suddenly, causing spillage or even accidents. In an industrial setting, a malfunctioning valve can mean defective products or dangerous working conditions.

Common Signs Your Hydraulic Control Valve is Failing

A failing hydraulic control valve rarely breaks down suddenly—it usually gives warning signs first. By paying attention to these early symptoms, you can catch problems before they escalate into catastrophic failures. Below are the most common indicators:

Loss of Hydraulic Power and Performance

When a valve isn’t functioning properly, hydraulic fluid may bypass internal components or flow inefficiently. This results in a noticeable loss of force or sluggish response.

- A backhoe might struggle to lift its bucket, even when the pump is running at full capacity.

- A press machine may fail to exert enough pressure on materials, reducing production quality.

This power loss is often due to internal leakage within the valve or a partially blocked flow path.

Erratic or Slow Operation of Equipment

If your machine’s movements become jerky, delayed, or inconsistent, the control valve could be the culprit.

- Jerky arm movements in excavators indicate a sticking spool.

- Slow extension of cylinders in industrial lifts signals possible fluid restriction.

This typically happens when contaminants cause the valve spool to stick or bind, preventing smooth fluid flow.

Unusual Noises: Whining, Hissing, or Knocking

Hydraulic systems are usually loud, but you’ll notice a distinct change in noise when valves begin to fail.

- Whining or high-pitched hissing often means cavitation (air bubbles in the hydraulic fluid).

- Knocking sounds can suggest misaligned or worn-out valve components.

If ignored, these noises can escalate into pump damage and total system failure.

Fluid Leaks and Pressure Drops

Visible leaks around the valve body or fittings are red flags. Even small drips can lead to major efficiency losses over time.

- Pressure gauges may show sudden drops, even when the pump is fully operational.

- Leaks also increase the risk of environmental hazards and slippery work areas.

Often, faulty seals or O-rings are to blame.

Overheating of Hydraulic System

If your hydraulic fluid feels excessively hot, it’s a strong indicator of trouble. A malfunctioning valve forces the pump to work harder, which generates excessive heat.

- Overheating leads to fluid breakdown, further accelerating valve wear.

- In severe cases, seals can melt or harden, worsening leaks.

Root Causes of Hydraulic Control Valve Failures

Hydraulic valve failure rarely happens in isolation—it’s usually the result of multiple contributing factors. Let’s explore the most common causes:

Contaminated Hydraulic Fluid

Fluid contamination is the number one cause of hydraulic valve problems. Even microscopic particles of dirt, rust, or metal shavings can damage valve spools.

- Solid contaminants scratch valve surfaces, causing leakage.

- Water contamination leads to rust, corrosion, and loss of lubrication.

- Air bubbles reduce efficiency and cause cavitation noise.

Excessive Wear and Tear

Hydraulic valves are exposed to constant pressure and flow fluctuations, leading to natural wear. Over time, valve spools lose their precise fit, resulting in internal leakage.

For example:

- A valve designed for 3,000 PSI may begin leaking internally after years of high-pressure cycles.

- Agricultural machinery, often exposed to dust and outdoor elements, experiences accelerated wear.

Faulty Seals and O-Rings

Seals and O-rings are small but critical components. If they crack, harden, or wear out, they cause external leaks and internal bypassing.

A damaged O-ring may seem minor, but it can drain system pressure quickly and lead to catastrophic machine failure.

Poor Maintenance Practices

Skipping regular servicing is one of the most preventable causes of valve failure. Neglect often results in:

- Dirty filters that allow contaminants into the valve.

- Improper lubrication, increasing friction.

- Uncalibrated systems, causing excess strain on components.

Regular maintenance not only saves money but also ensures safe operation.

Diagnostic Methods for Hydraulic Control Valve Problems

Identifying whether a hydraulic valve is truly failing requires more than guesswork. Professionals use a combination of visual inspections, measurements, and specialized equipment.

Visual Inspection of Components

This is the first step in troubleshooting. Look for:

- Oil leaks around seals and connections.

- Physical damage such as cracks or bent spools.

- Corrosion on exposed valve parts.

A simple flashlight inspection can reveal early signs of damage before they escalate.

Hydraulic Pressure Testing

Using pressure gauges, technicians compare actual pressure readings with manufacturer specifications.

- Low pressure often signals internal leakage.

- Fluctuating readings indicate spool sticking or pump inefficiency.

This test helps pinpoint whether the problem lies in the valve or another system component.

Monitoring Fluid Condition

Regular fluid checks reveal much about valve health:

- Dark or burnt-smelling oil indicates overheating.

- Cloudy fluid suggests water contamination.

- Metallic particles point to component wear.

Many companies now use oil analysis labs for detailed reports on fluid condition.

Using Flow Meters and Sensors

Advanced diagnostic tools like flow meters and temperature sensors provide real-time insights:

- Detect whether valves are restricting flow.

- Identify sudden drops in efficiency.

- Reveal whether heat buildup is valve-related.

This data helps in making informed repair or replacement decisions.

Effective Solutions to Fix Failing Hydraulic Control Valves

When you notice the warning signs of a failing valve, it’s crucial to act quickly. Depending on the severity of the issue, solutions can range from simple maintenance to full valve replacement.

Cleaning and Flushing the Hydraulic System

If contamination is the culprit, a system flush may be enough to restore valve performance.

- Use manufacturer-recommended cleaning fluids or hydraulic oil to remove debris and sludge.

- Install temporary high-efficiency filters to capture loose particles after flushing.

- In severe cases, components may need to be ultrasonically cleaned to eliminate fine contaminants.

Replacing Seals, O-Rings, and Worn Parts

Many valve issues originate from deteriorated seals. Replacing them is a cost-effective solution compared to buying a new valve.

- Always use OEM (Original Equipment Manufacturer) parts to ensure compatibility.

- Check for scoring or scratches on spools—if severe, machining or replacement is necessary.

- Re-lubricate moving components after reassembly.

Even small parts like seals play a massive role in maintaining system integrity.

Professional Valve Repair or Replacement

When valves are beyond simple fixes, professional repair services can rebuild them. This involves:

- Disassembling the valve to inspect internal wear.

- Re-machining spools and bores to restore tolerances.

- Testing repaired valves under pressure before reinstallation.

If the valve is too damaged, replacement is the most reliable option. While costly upfront, it prevents repeated breakdowns and saves money long term.

Scheduled Preventive Maintenance

The most effective “solution” is prevention. Maintenance routines should include:

- Filter changes every 500 hours (or as recommended).

- Routine inspections for leaks, cracks, or sticking spools.

- System calibration checks to keep operations smooth.

Think of it as “cheap insurance”—a little effort upfront prevents big expenses later.

Preventive Measures to Extend Valve Lifespan

Hydraulic valves are designed to last thousands of hours, but only if treated properly. Preventive measures not only extend lifespan but also improve machine reliability.

Proper Fluid Filtration and Regular Checks

Clean fluid is the lifeblood of any hydraulic system. Studies show that 80% of hydraulic failures are due to contamination.

- Install high-quality inline filters to trap particles.

- Replace filters regularly instead of waiting until they clog.

- Perform oil analysis every few months to track contamination levels.

Clean oil = longer valve life.

Correct Installation and Alignment

A valve that’s misaligned or incorrectly mounted can cause uneven pressure distribution, leading to premature wear.

- Always follow manufacturer torque specifications during installation.

- Ensure hoses and fittings are correctly aligned to avoid vibration stress.

- Double-check for leaks after installation.

Correct setup prevents costly rework later.

Timely Servicing and Component Replacement

Every machine component has a service life. Ignoring this schedule puts the entire system at risk.

- Replace seals, gaskets, and O-rings before they fail.

- Service pumps and motors on time to prevent overloading valves.

- Keep a maintenance logbook for consistent tracking.

An organized maintenance routine ensures reliability across the system.

When to Seek Professional Help

Not every hydraulic issue requires a technician, but there’s a fine line between DIY maintenance and complex repairs that demand expertise.

DIY Troubleshooting vs. Expert Intervention

Some problems are manageable in-house:

- Checking oil levels.

- Replacing filters.

- Tightening fittings.

However, when it comes to internal valve repairs, precision machining, or advanced diagnostics, it’s best to call a professional. Attempting complex repairs without training can make the problem worse—and more expensive.

Choosing a Reliable Hydraulic Repair Service

Selecting the right service provider is just as important as the repair itself.

Look for:

- Experience: Providers with proven track records in your industry.

- Testing Facilities: Shops that pressure-test valves before returning them.

- OEM Certification: Ensures genuine parts and adherence to standards.

- Warranty: Guarantees peace of mind.

Investing in professional help ensures long-term reliability and fewer unplanned breakdowns.

Conclusion

The hydraulic control valve is truly the heartbeat of your hydraulic system. When it starts to fail, the consequences ripple across the entire machine—reducing performance, increasing downtime, and creating safety risks.

The good news is that most valve failures can be prevented with regular maintenance, clean hydraulic fluid, and timely repairs. Paying attention to warning signs like leaks, overheating, and erratic movements allows you to act before small issues turn into major breakdowns.

When in doubt, always consult a professional hydraulic service provider. They have the tools, expertise, and testing facilities to ensure your valves are restored to peak performance.

By combining preventive care with professional support, you can extend the lifespan of your hydraulic valves, reduce costs, and keep your machinery running smoothly—no matter how demanding the job.

FAQs

Many operators, technicians, and equipment owners share similar concerns about hydraulic valve performance. Here are the most frequently asked questions—answered with expert insights.

Q1: How do I know if my hydraulic control valve is failing?

A: The most common signs include loss of hydraulic power, jerky or slow movements, overheating, fluid leaks, and unusual noises like hissing or whining. If you notice multiple symptoms together, it’s a strong indication the valve needs servicing.

Q2: Can a hydraulic control valve be repaired instead of replaced?

A: Yes, in many cases. If the problem is due to seal failure, contamination, or minor spool wear, repairs are possible. Professionals can re-machine spools, replace seals, and clean components to restore performance. However, if the valve body is cracked or severely worn, replacement is the safer option.

Q3: How often should hydraulic valves be serviced?

A: A general recommendation is to inspect and service valves every 500–1000 operating hours, depending on the application. High-duty machines (like excavators in mining) may require more frequent checks than light-duty equipment.

Q4: What happens if I ignore hydraulic valve problems?

A: Ignoring valve issues leads to reduced efficiency, higher energy costs, and eventually complete system failure. In severe cases, other components like pumps and actuators may get damaged, multiplying repair costs.

Q5: What type of hydraulic fluid is best for preventing valve damage?

A: Always use the manufacturer-recommended hydraulic fluid. Using the wrong oil can cause seal swelling, corrosion, or loss of lubrication. More importantly, ensure the fluid is always clean and filtered.

Q6: Can I clean or service a hydraulic control valve myself?

A: You can handle basic cleaning and filter changes. However, tasks like disassembling, re-machining, or recalibrating valves should only be done by certified hydraulic technicians. Attempting these repairs without proper tools can lead to costly mistakes.