Introduction

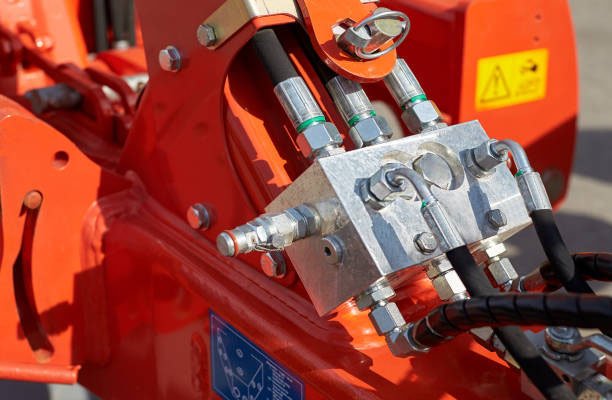

Hydraulic fittings on tractor systems have become critical components in ensuring smooth and efficient operation. From powering attachments like loaders and backhoes to managing steering and braking systems, hydraulics play a vital role in a tractor’s functionality. While much attention often goes to the pump or hydraulic fluid, it’s the fittings—the small but mighty connectors—that hold the system together and prevent costly failures.

Hydraulic fittings on tractor are essential for sealing hydraulic lines, maintaining pressure, and preventing leaks. A single faulty fitting can lead to downtime, costly repairs, and safety risks. This article dives deep into everything you need to know—from identifying the right fittings to ensuring leak-proof installations.

Understanding Tractor Hydraulic Systems

Modern tractors rely heavily on hydraulics to perform labor-intensive tasks with ease. These systems work by transmitting pressurized fluid through hoses and cylinders to generate motion or force.

Core Components of a Hydraulic System

- Hydraulic Pump: Generates pressure.

- Hydraulic Cylinder or Motor: Converts pressure into mechanical force.

- Valves: Control fluid flow.

- Reservoir: Stores the hydraulic fluid.

- Hoses and Fittings: Carry and connect fluid lines.

How Hydraulics Enhance Tractor Efficiency

Hydraulics reduce manual effort, increase lifting power, and enable multitasking with attachments. Precision control of equipment like front-end loaders or post hole diggers hinges on a leak-free, high-pressure system—anchored by durable and correctly installed fittings.

What Are Hydraulic Fittings?

Hydraulic fittings are connectors that join hoses, pipes, and tubes in a hydraulic system. They play a critical role in preventing leaks, maintaining system pressure, and ensuring compatibility between different components.

Function of Hydraulic Fittings

- Connect hydraulic lines securely

- Prevent fluid loss and air entry

- Withstand high-pressure environments

- Facilitate easy maintenance and disassembly

Hydraulic fittings come in various designs, each tailored to different pressure ratings, fluid types, and mechanical configurations.

Types of Hydraulic Fittings Used on Tractors

Hydraulic fittings come in various shapes, thread types, and sealing mechanisms. Selecting the correct type ensures a secure, leak-free connection that matches your tractor’s hydraulic setup.

O-Ring Face Seal (ORFS)

- Description: Features a flat sealing surface with an embedded O-ring that provides a reliable seal when tightened.

- Best Use: High-pressure applications prone to vibration.

- Advantages: Excellent for preventing leaks even in dynamic or high-stress environments.

JIC (Joint Industry Council) Fittings

- Description: Has a 37° flare seating surface. Commonly used in North American machinery.

- Best Use: Medium to high-pressure systems.

- Advantages: Readily available and versatile; compatible with many tractor brands.

NPT (National Pipe Thread)

- Description: A tapered thread fitting that seals by metal-to-metal wedging.

- Best Use: Lower-pressure systems or static connections.

- Advantages: Economical, but requires sealant like Teflon tape to prevent leaks.

BSP (British Standard Pipe)

- Description: Popular in European and international equipment, uses parallel or tapered threading.

- Best Use: Older or non-U.S. manufactured tractors.

- Advantages: Global compatibility; requires matching threads for proper sealing.

Each fitting type serves specific system requirements, and using mismatched threads (e.g., JIC with NPT) can lead to dangerous leaks or pressure drops.

Material Choices for Hydraulic Fittings

Choosing the right material for your hydraulic fittings isn’t just about durability—it impacts safety, performance, and lifespan.

Steel Hydraulic Fittings

- Strength: High tensile strength and excellent pressure tolerance.

- Use Case: Heavy-duty, high-pressure tractor hydraulics.

- Drawback: Susceptible to corrosion unless coated or plated.

Brass Hydraulic Fittings

- Strength: Moderate strength, but more malleable than steel.

- Use Case: Lower-pressure or specialty applications.

- Drawback: Prone to deformation under high torque or extreme pressure.

Stainless Steel Fittings

- Strength: Combines high strength with exceptional corrosion resistance.

- Use Case: Harsh environments (e.g., marine or fertilizer sprayers).

- Drawback: More expensive than other materials, but lasts longer.

Corrosion Resistance & Strength Comparison

| Material | Pressure Rating | Corrosion Resistance | Typical Cost |

|---|---|---|---|

| Steel (zinc-plated) | High | Moderate | $$ |

| Brass | Medium | High | $$ |

| Stainless Steel | High | Excellent | $$$$ |

Your selection should factor in exposure to chemicals, pressure levels, and temperature variations.

How to Identify the Right Hydraulic Fitting

Picking the correct hydraulic fitting can feel like solving a puzzle. With so many thread types and sizes, even seasoned farmers can get confused.

Measuring Thread Size

- Use thread pitch gauges to identify the spacing of threads.

- Calipers help measure the outer and inner diameters.

- Match these measurements with fitting charts (available online or in-store) for accuracy.

Matching Port Types

- Identify if your hydraulic port is tapered (NPT) or flat-faced (ORFS).

- Use visual inspection or manufacturer specifications to determine compatibility.

Using Thread Identification Tools

Many hydraulic supply stores offer thread ID kits or apps that help identify fitting types based on dimensions and thread patterns. You can also purchase reusable tools to test on-site.

Pro Tip: Always keep a few fitting samples or labeled photos on your phone to compare when buying replacements.

Top Brands for Tractor Hydraulic Fittings

Choosing a trusted brand ensures you get fittings that are durable, leak-proof, and precisely machined. Here are some of the most reliable names in the hydraulic fitting industry for tractors:

Parker Hannifin

- Reputation: Industry leader with decades of experience in hydraulic technologies.

- Products: Offers a wide range of ORFS, JIC, and NPT fittings.

- Why Farmers Trust Them: Consistent quality, global availability, and comprehensive technical support.

Eaton Weatherhead

- Reputation: Known for manufacturing robust fittings used in agriculture and heavy machinery.

- Products: Hydraulic hoses, fittings, adapters, and complete fluid systems.

- Highlight: Their “Dura-Kote” coating offers superior corrosion resistance.

Gates Corporation

- Reputation: Globally recognized for hoses and hydraulic components.

- Products: High-performance hose assemblies and leak-free connectors.

- Advantage: Ideal for harsh, outdoor agricultural environments.

DiscountHydraulicHose.com

- Reputation: Reliable online supplier offering budget-friendly yet quality fittings.

- Products: Large selection of standard and hard-to-find fittings.

- Why Choose Them: Fast shipping and detailed product specs for DIY tractor owners.

Tip: Always compare thread types and pressure ratings across brands to ensure compatibility with your tractor’s system.

Installation Guide for Tractor Hydraulic Fittings

Installing hydraulic fittings properly is critical to prevent leaks, maintain pressure, and ensure safe operation. Here’s a step-by-step guide you can follow:

Tools You’ll Need

- Adjustable wrenches

- Thread sealant (for NPT fittings)

- Clean rags

- Torque wrench (recommended)

- Safety gloves and eyewear

Step-by-Step Installation Process

- Depressurize the System:

- Shut off the tractor engine and relieve all hydraulic pressure.

- Open valve controls to release trapped pressure in hoses.

- Clean the Connections:

- Use a lint-free cloth to wipe dirt, oil, or debris from all fitting ends.

- Clean threads and sealing surfaces thoroughly.

- Apply Thread Sealant (if needed):

- For NPT fittings, apply Teflon tape or thread paste sparingly on male threads.

- Avoid applying sealant to the first thread to prevent contamination.

- Hand-Tighten the Fitting:

- Begin threading the fitting by hand to avoid cross-threading.

- Ensure it aligns correctly with the port or hose.

- Tighten with Wrench:

- Use a torque wrench where possible to apply correct torque.

- Overtightening can damage threads and lead to leaks.

- Test the System:

- Restart the tractor and activate the hydraulic system.

- Inspect all fittings under pressure for signs of leaks or hissing sounds.

Pro Tip: Always double-check torque specifications based on fitting type and material.

Common Mistakes During Installation

Even seasoned tractor owners make fitting mistakes that can cost time, money, and performance. Here are the most frequent errors to avoid:

1. Over-Tightening

- Over-torquing damages threads, deforms seals, and increases the risk of cracking.

- Use a torque chart or manufacturer guide to apply appropriate force.

2. Mismatched Thread Types

- Connecting BSP to NPT or JIC to ORFS will not form a proper seal.

- Always verify the thread type using identification tools or fitting charts.

3. Reusing Damaged Fittings

- Old fittings may have worn threads or flattened O-rings.

- Always inspect for wear and replace if in doubt.

4. Ignoring Cleanliness

- Dirt and grit can destroy seals and cause internal contamination.

- Always clean ports and threads before and during installation.

5. Skipping Leak Tests

- Just because it looks tight doesn’t mean it’s sealed.

- Test under pressure to confirm a leak-free connection before field operation.

Signs of Hydraulic Fitting Failure

Recognizing early warning signs of fitting failure can prevent costly breakdowns and hazardous conditions in the field. Hydraulic fittings are under constant stress and can deteriorate over time. Here’s what to watch for:

1. Leaks and Drips

- What It Looks Like: Visible oil spots near fittings, hose connections, or under the tractor.

- Causes: Worn-out seals, loose fittings, cracked connectors, or cross-threading.

- Solution: Inspect and replace faulty fittings immediately.

2. Pressure Loss

- What It Looks Like: Sluggish loader response, reduced lifting power, or incomplete movement.

- Causes: Internal leaks, partially blocked fittings, or loose connections.

- Solution: Pressure test the system to locate the issue, and ensure fittings are secure.

3. Unusual Noises

- What It Sounds Like: Hissing, whining, or vibrating sounds when operating hydraulic attachments.

- Causes: Air entering the system via damaged fittings or poor sealing.

- Solution: Bleed the hydraulic system and check all fitting interfaces for air leaks.

4. Fluid Discoloration

- What It Looks Like: Milky or darkened hydraulic fluid.

- Causes: Contamination from external dirt entering through faulty fittings.

- Solution: Replace fluid and fittings; install protective dust caps.

Warning: Ignoring these symptoms can lead to sudden system failure and expensive repair bills.

How to Prevent Leaks in Hydraulic Systems

Leaks are a common yet preventable issue in tractor hydraulic systems. Follow these best practices to keep your fittings sealed tight and leak-free.

1. Use Proper Torque

- Always use a torque wrench, especially on JIC and ORFS fittings, to apply manufacturer-recommended torque.

- Avoid guessing or over-tightening.

2. Select the Right Sealant

- Use Teflon tape or liquid thread sealant only for NPT fittings.

- Avoid using any sealant on ORFS or JIC fittings—these rely on mechanical sealing surfaces.

3. Inspect Sealing Surfaces

- Check for burrs, scratches, or nicks on flare faces and O-rings.

- Replace damaged parts instead of trying to “tighten the leak away.”

4. Maintain Cleanliness

- Keep fitting caps on until installation.

- Clean hose ends, adapters, and ports with lint-free cloths before connection.

5. Schedule Regular System Checks

- Visually inspect fittings during pre-season prep and post-harvest maintenance.

- Monitor for signs of loosening, wear, or damage.

Maintenance Hack: Keep a maintenance logbook with fitting checkups scheduled every 100-200 operating hours.

Maintenance Tips for Long-Lasting Fittings

Proper maintenance extends the life of your hydraulic fittings and keeps your tractor running at peak efficiency.

1. Clean Fittings After Use

- Wipe fittings with a clean cloth after every job to remove dirt and debris.

- Use mild solvent for stubborn grime—but avoid corrosive cleaners.

2. Check Seals and O-Rings

- O-rings degrade over time due to heat, pressure, and fluid exposure.

- Replace them periodically even if no leaks are present, especially before planting or harvest seasons.

3. Store Spare Fittings Properly

- Store unused fittings in dry, dust-free containers with labeled compartments.

- Avoid exposure to sunlight, chemicals, or moisture.

4. Lubricate Threads Before Installation

- A drop of clean hydraulic oil can prevent galling on metal threads during installation.

- Never use grease or non-compatible oils.

5. Replace Before They Fail

- Don’t wait for a leak—replace fittings showing signs of rust, flattening, or stress.

- Plan a pre-season maintenance check to replace all aged connectors.

Replacing Hydraulic Fittings: When and How?

Timely replacement of hydraulic fittings is essential to avoid unexpected system failures, especially during critical agricultural operations. Here’s how to know when it’s time and how to do it properly.

When Should You Replace Hydraulic Fittings?

- Persistent Leaks: If tightening doesn’t fix the issue, the fitting is likely worn or cracked.

- Visible Damage: Look for corrosion, thread wear, flattened O-rings, or distorted flare faces.

- System Performance Drops: Inconsistent pressure, noise, or unresponsive hydraulics can indicate failing fittings.

- Scheduled Maintenance: Proactively replacing fittings during annual servicing prevents downtime.

How to Replace Hydraulic Fittings (Step-by-Step)

- Depressurize and Drain:

- Turn off the tractor engine.

- Engage hydraulic controls to release any remaining pressure.

- Drain fluid from the affected hose or system section.

- Remove Old Fitting:

- Use wrenches to loosen the old fitting.

- Inspect both male and female threads for signs of wear or cross-threading.

- Prepare New Fitting:

- Clean all contact surfaces.

- Apply thread sealant if using NPT-style fittings.

- Install New Fitting:

- Thread by hand first to avoid cross-threading.

- Tighten using appropriate torque.

- Test the System:

- Refill hydraulic fluid.

- Power up the system and check for leaks.

DIY vs Professional Replacement: While basic replacements are doable for most tractor owners, complex systems or hard-to-reach areas may require professional service to ensure proper sealing and pressure testing.

Hydraulic Adapters vs Hydraulic Fittings

Hydraulic adapters and fittings are often confused, but they serve distinct purposes in a tractor’s hydraulic system.

What Are Hydraulic Adapters?

- Function: Connect two different types of threads or hose sizes.

- Example: Adapting a JIC hose end to a BSP port.

- Best Use: When retrofitting equipment, using foreign-made implements, or modifying systems.

What Are Hydraulic Fittings?

- Function: Join hoses to ports or components with a direct match in thread and type.

- Example: JIC-to-JIC, ORFS-to-ORFS connections.

Key Differences

Feature Hydraulic Fittings Hydraulic Adapters Purpose Direct connection Transition between types/sizes Thread Match Same type and size Different threads or sizes Typical Use Standard OEM configurations Modifications or international parts Leak Risk Lower (if matched) Slightly higher (due to complexity) Tip: Always confirm both ends of the connection before using an adapter. Using the wrong type can reduce pressure capacity and introduce leak points.

Cost of Hydraulic Fittings for Tractors

Hydraulic fittings are a small investment that protects a large one—your tractor. Prices vary based on type, material, brand, and quantity.

Cost Breakdown by Type

Fitting Type Material Average Price (USD) ORFS Steel $5 – $12 JIC Brass $4 – $9 NPT Stainless Steel $6 – $15 BSP Steel/Brass $5 – $10

Budgeting Tips for Farmers

- Buy a Kit: Pre-packaged hydraulic fitting kits with common sizes save time and money.

- Order Online in Advance: Avoid emergency markups from local stores by keeping a small inventory.

- Avoid Cheap Knock-Offs: Low-quality fittings may not meet pressure standards and can fail quickly.

Farmer Insight: Investing $100 in quality fittings today could prevent $1,000+ in downtime and repair costs tomorrow.

Where to Buy Quality Hydraulic Fittings

Getting the right hydraulic fittings means sourcing from trusted suppliers who offer verified products, technical guidance, and fair prices. Here’s a comparison of options to help you make informed purchasing decisions.

1. Online Retailers

- Pros:

- Wide variety of fittings and adapters

- Competitive pricing and seasonal discounts

- Customer reviews and detailed product specs

- Cons:

- Shipping time (especially in remote areas)

- Risk of ordering wrong thread type if unsure

2. Local Hydraulic Supply Stores

- Pros:

- In-person guidance and product inspection

- Immediate availability

- Helpful for emergency replacements

- Cons:

- Limited inventory compared to online

- Higher pricing in some areas

3. OEM Dealerships

- Pros:

- Guaranteed compatibility with your tractor model

- OEM-grade parts and support

- Cons:

- Higher price tag

- Less flexibility with mixed-brand setups

Tip: Always keep the part number or fitting sample with you when shopping to ensure you get an exact match.

Conclusion

Hydraulic fittings on tractors may be small, but their role is huge. They ensure your machinery operates efficiently, safely, and without leaks under intense pressure. Understanding the right fitting types, materials, and installation practices will save you from downtime and expensive repairs.

By choosing quality parts, practicing regular maintenance, and responding quickly to signs of failure, you keep your tractor’s hydraulic system in peak condition season after season. Whether you’re a DIY-minded farmer or rely on a local mechanic, this knowledge empowers you to make smarter decisions for your equipment and your farm.

FAQs

1. Can I mix different types of hydraulic fittings?

No, mixing thread types (e.g., JIC with NPT) can lead to poor seals, leaks, and pressure failures. Always use compatible fittings or proper adapters.

2. How do I know if a fitting is high-pressure rated?

Check the product specs or packaging. Most fittings are labeled with PSI ratings. For tractors, always choose fittings rated above 3,000 PSI for safety.

3. Is it safe to reuse old hydraulic fittings?

Not recommended. Threads, seals, and surfaces degrade with use. Reusing may save money short-term but risks leaks and system damage.

4. What thread sealant should I use?

Use Teflon tape or liquid pipe sealant only on tapered thread fittings like NPT. Never use sealant on flare-type or O-ring fittings like JIC or ORFS.

5. Are hydraulic adapters as reliable as fittings?

Yes—if installed properly. Quality adapters are safe and effective but introduce an extra connection point, which slightly increases leak risk.

6. How often should I inspect my hydraulic fittings?

Ideally, inspect them every 100–200 operating hours or before each planting/harvest season. Check for leaks, wear, and signs of corrosion.