Hydraulic fluid dynamics is a cornerstone of modern engineering, powering everything from cars and airplanes to massive industrial machinery. This field focuses on understanding how liquids behave under pressure and motion, unlocking incredible applications that impact our daily lives. In this blog, we’ll dig deeper into the principles, applications, challenges, and advancements in hydraulic fluid dynamics to give you a solid understanding of its importance.

What is Hydraulic Fluid Dynamics?

Hydraulic fluid dynamics is the study of how liquids flow, particularly in systems that generate or transmit power using pressure. At its core, this field combines principles from physics and engineering to manipulate fluids like hydraulic oil or water to perform work. The science isn’t just about moving liquid—it’s about controlling and optimizing that movement to generate efficient energy transfer.

Think about it this way: when you push a syringe filled with water, the pressure inside the syringe forces the water out. Now imagine scaling that principle up to lift a multi-ton piece of equipment—welcome to the magic of hydraulic systems!

The Role of Fluids in Energy Transmission

Fluids are an ideal medium for energy transmission because they are incompressible (mostly), allowing for precise control. When a hydraulic fluid is pressurized within a system, that pressure can be harnessed to create motion, lift heavy loads, or generate force. Without the science of hydraulic fluid dynamics, many of the machines and tools we rely on would be far less efficient or even impossible to operate.

The Key Principles of Hydraulic Fluid Dynamics

Let’s break down the key concepts that make hydraulic systems tick. These principles form the foundation of how hydraulic systems are designed and maintained.

1. Pascal’s Law: The Power Multiplier

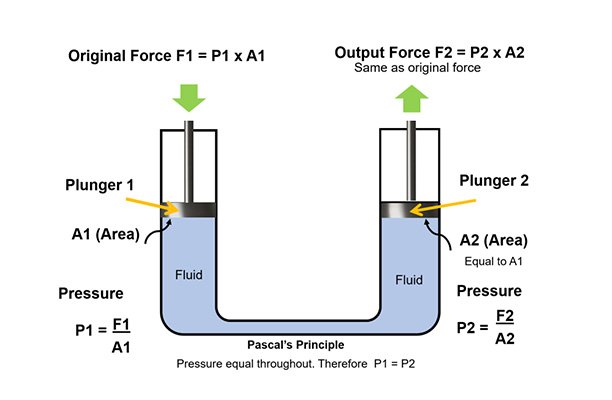

Pascal’s Law states that when pressure is applied to a confined fluid, it is transmitted equally in all directions. This principle is why hydraulic systems are so powerful. For instance, in a car’s braking system, a small force applied to the brake pedal is multiplied through the hydraulic fluid, creating enough pressure to stop a vehicle weighing thousands of pounds.

This law is also what enables hydraulic presses to exert massive force—turning a small input force into an output strong enough to shape steel.

2. Flow Rate: The Speed of Power

Flow rate measures how quickly fluid moves through a hydraulic system and plays a critical role in system efficiency. A high flow rate means faster operation, but it can also create turbulence, reducing efficiency and increasing wear. Conversely, a low flow rate ensures smoother operation but might slow down system performance.

3. Viscosity: The Right Balance

Viscosity refers to a fluid’s resistance to flow. It’s a balancing act—fluids that are too viscous can create excessive resistance, causing inefficiency. On the other hand, fluids that are too thin may not generate enough pressure for the system to function correctly. Engineers carefully select the right fluid viscosity for each application to strike the perfect balance.

4. Pressure Drops and Friction Losses

As fluids move through pipes, hoses, and valves, they encounter resistance, which leads to pressure drops. Friction between the fluid and the walls of the system causes energy loss, reducing the overall efficiency of the system. Minimizing these losses is a critical focus of hydraulic system design, achieved by using smoother pipes, proper fittings, and efficient layouts.

Applications of Hydraulic Fluid Dynamics

Hydraulic fluid dynamics plays a role in a surprising variety of industries, from transportation to energy production. Let’s explore these applications in greater detail:

1. Automotive Systems

Hydraulics make driving safer and more convenient.

- Hydraulic Brakes: This application is a perfect example of Pascal’s Law. When you press your brake pedal, hydraulic fluid transmits that force to the brake pads, creating enough pressure to stop the vehicle. This system allows for minimal physical effort with maximum stopping power.

- Power Steering: Hydraulic steering systems use fluid to make turning the steering wheel almost effortless, especially at low speeds. Without hydraulics, every turn of the wheel would feel like a workout!

2. Construction and Heavy Machinery

The construction industry relies heavily on hydraulic systems for power and precision.

- Excavators and Cranes: Hydraulic systems allow these machines to lift heavy loads with ease, often in precise movements that would be impossible with mechanical systems alone.

- Bulldozers and Loaders: These machines use hydraulics to push, lift, and transport massive amounts of material efficiently.

3. Manufacturing and Robotics

In the manufacturing world, hydraulic systems are indispensable.

- Hydraulic Presses: These machines shape, cut, or compress materials with incredible force, thanks to hydraulic systems. For example, they’re used in automobile manufacturing to mold car parts.

- Robotics: Many industrial robots use hydraulics for smooth, precise, and powerful movements, enabling automation in industries like electronics and food processing.

4. Aerospace and Aviation

Safety and reliability are paramount in aviation, and hydraulics are a big reason why:

- Landing Gear Systems: Hydraulic systems control the deployment and retraction of landing gear.

- Flight Controls: Hydraulics help adjust flaps, rudders, and other critical control surfaces during flight.

5. Renewable Energy

Hydraulic systems also support the green energy revolution:

- Hydroelectric Power: Hydraulic turbines convert the kinetic energy of moving water into electricity, making it one of the most efficient renewable energy sources.

- Wind Turbine Controls: Many wind turbines use hydraulic systems for blade pitch adjustment, ensuring optimal performance in varying wind conditions.

The Importance of Efficiency in Hydraulic Systems

Efficiency isn’t just a buzzword—it’s critical to the performance and longevity of hydraulic systems. Here’s why it matters:

- Energy Savings: Efficient systems use less energy to perform the same tasks, reducing costs and environmental impact.

- Reduced Wear and Tear: Optimized systems experience less mechanical stress, extending the life of components like pumps, valves, and hoses.

- Increased Safety: Systems that operate smoothly and predictably are less likely to fail, reducing the risk of accidents.

Challenges in Hydraulic Fluid Dynamics

While hydraulic systems are incredibly versatile, they’re not without their challenges.

1. Heat Buildup

Friction within the fluid and system components generates heat, which can reduce efficiency and damage components if not managed properly. Cooling systems or heat exchangers are often added to combat this issue.

2. Fluid Contamination

Contaminants like dirt, water, or air can wreak havoc on a hydraulic system, causing blockages, corrosion, or erratic behavior. Preventing contamination requires robust filtration systems and regular maintenance.

3. System Leaks

Leaks not only reduce efficiency but can also be a safety hazard. Detecting and fixing leaks promptly is essential to maintaining a system’s performance.

Conclusion

Hydraulic fluid dynamics is more than just a technical field—it’s the invisible force powering industries, innovations, and everyday life. From making cars safer to driving the green energy revolution, this science is crucial to modern engineering. With ongoing advancements, hydraulic systems are becoming smarter, more efficient, and more environmentally friendly.

FAQs

1. What kind of fluids are used in hydraulic systems?

Hydraulic systems typically use mineral oils, synthetic fluids, or water-based solutions. These fluids are specially formulated to handle high pressure and resist wear and tear.

2. Why is pressure loss a problem in hydraulic systems?

Pressure loss reduces the efficiency of energy transfer, meaning the system has to work harder to achieve the same result, which increases energy consumption and wear.

3. How often should hydraulic systems be maintained?

Maintenance schedules vary based on the system, but regular checks for fluid levels, leaks, and contamination should be conducted monthly or even weekly for critical systems.

4. Can hydraulic systems work in cold weather?

Yes, hydraulic systems can work in cold weather, but special low-temperature hydraulic fluids are often required. These fluids maintain proper viscosity even in freezing conditions, ensuring smooth operation.

5. What’s the difference between hydraulic and pneumatic systems?

Hydraulic systems use liquids like oil to transmit power, while pneumatic systems use compressed air. Hydraulic systems are better for heavy-duty applications requiring high force, whereas pneumatic systems are typically used for lighter, faster tasks.

6. How long do hydraulic systems typically last?

With proper maintenance, hydraulic systems can last for decades. Regularly changing fluids, checking for leaks, and keeping components clean can significantly extend their lifespan.