Hydraulic hoses may appear to be just a small part of a complex hydraulic system, but their size plays a crucial role in determining overall system efficiency and performance. Choosing the wrong hydraulic hose size can result in pressure drops, overheating, and even complete system failure. So, how do you ensure you get it right? The key lies in understanding how hydraulic hose size impacts fluid flow, pressure capacity, and the specific requirements of your application.

In this blog, we’ll cover everything you need to know about hydraulic hose sizes, including why size matters, how to measure hoses, and tips for selecting the right one for your application. Whether you’re an industry professional or just starting out, this guide will simplify the process for you.

Let’s get started, shall we?

Why Hydraulic Hose Size Matters

Hydraulic systems are all about moving fluid under pressure to perform work. To accomplish this, the hydraulic hose needs to meet the system’s specific flow, pressure, and environmental demands. Here’s why size plays such a critical role:

1. Flow Capacity

Hydraulic hoses are responsible for transferring fluid from one component to another. The hose’s inside diameter (ID) directly affects how much fluid can flow through it at any given time.

- A small ID restricts flow, causing pressure loss and heat buildup in the system. This can lead to inefficiency and potential equipment damage.

- A large ID, on the other hand, might reduce pressure losses but could compromise the system’s efficiency if the fluid velocity becomes too low.

For instance, if your system requires 10 gallons per minute (GPM) flow rate but you’re using a hose that only supports 7 GPM, the system won’t perform as expected, and you’ll see increased wear and tear.

2. Pressure Ratings

The pressure rating of a hydraulic hose depends on its size. Smaller hoses generally have thicker walls, making them capable of withstanding higher pressures.

- Using an undersized hose could cause it to rupture under high pressure, leading to dangerous failures.

- Using an oversized hose could result in a lower pressure capacity due to thinner walls, especially in applications requiring high pressure.

3. System Compatibility

Every hydraulic system is designed with specific flow rates, fittings, and pressure requirements in mind. A mismatched hose size may result in:

- Leaks due to improper fitting connections

- Accelerated wear of system components

- Reduced overall system efficiency

4. Safety Considerations

Incorrect hose sizing can create safety hazards. Undersized hoses may burst under high pressure, while oversized hoses could slip off fittings or create excessive vibration. Ensuring proper sizing minimizes risks and ensures a safer work environment.

The Key Takeaway

Choosing the right size isn’t just about convenience—it’s about optimizing performance, enhancing safety, and prolonging the life of your system.

Hydraulic Hose Sizing Basics

To find the correct hydraulic hose size, there are a few key measurements and factors you need to consider:

1. Inside Diameter (ID)

The inside diameter is arguably the most important measurement when it comes to hydraulic hoses. It determines how much fluid can flow through the hose at a given time.

- Why it matters:

A smaller ID restricts fluid flow, increasing velocity and pressure loss. If the ID is too large, the fluid flow may be insufficient, causing inefficiencies. - How to measure:

Use calipers or refer to the hose’s specifications to determine the ID. Common sizes are measured in inches or millimeters.

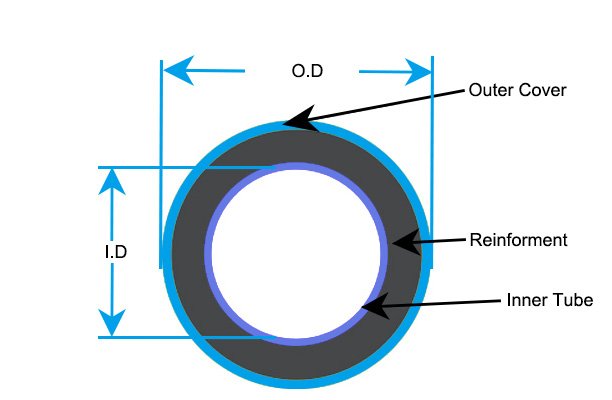

2. Outside Diameter (OD)

The OD is the total width of the hose, including the inner tube, reinforcement layers, and outer cover. While OD doesn’t directly affect fluid flow, it’s essential for fitting compatibility and ensuring the hose fits properly in confined spaces.

3. Hose Length

The hose length should account for both the distance between components and any potential movement or flexing. Always add extra length for bends, routing, and vibration to avoid unnecessary stress on the hose.

4. Hose Dash Size

Hydraulic hoses are often referred to by their dash size, which corresponds to the ID in sixteenths of an inch. For example:

- Dash 04 (-4) = 1/4 inch ID

- Dash 06 (-6) = 3/8 inch ID

- Dash 08 (-8) = 1/2 inch ID

5. Flow Rate and Velocity

The size of the hose affects the velocity of the hydraulic fluid. Aim for a balanced velocity that’s not too high (causing turbulence) or too low (causing inefficiency).

How to Measure a Hydraulic Hose

Measuring a hydraulic hose isn’t rocket science, but it does require some attention to detail. Here’s a step-by-step guide:

- Measure the ID:

Use a caliper to measure the inside diameter. Make sure the hose isn’t deformed while measuring. - Determine the OD:

Check the outer diameter for compatibility with fittings and clamps. - Measure the Length:

Lay the hose flat and use a tape measure to determine the total length. Account for any bends or curves if the hose is routed through complex paths. - Check Manufacturer Specs:

Always cross-check your measurements with the manufacturer’s specifications to ensure accuracy.

Common Hydraulic Hose Sizes and Their Applications

Different systems and applications require specific hydraulic hose sizes. Here’s a quick rundown of common sizes and where they’re typically used:

1. Small Hoses (Dash 04 to Dash 06)

- Size: 1/4 inch to 3/8 inch ID

- Applications: High-pressure systems with limited flow, such as hydraulic jacks, tools, and compact equipment.

- Benefits: High-pressure ratings and flexibility for tight spaces.

2. Medium Hoses (Dash 08 to Dash 12)

- Size: 1/2 inch to 3/4 inch ID

- Applications: General-purpose hydraulics, including agricultural equipment and industrial machinery.

- Benefits: Balanced flow capacity and pressure handling.

3. Large Hoses (Dash 16 and Above)

- Size: 1 inch ID and larger

- Applications: Heavy-duty systems like construction equipment, oil rigs, and large-scale industrial applications.

- Benefits: High flow rates for demanding tasks.

Tips for Choosing the Right Hydraulic Hose Size

When selecting a hydraulic hose, keep the following tips in mind:

- Follow the STAMP Method:

- Size: Ensure the ID and OD match your system’s requirements.

- Temperature: Verify the hose can handle the operating temperature range.

- Application: Consider the specific needs of your equipment or process.

- Material: Choose a material compatible with the hydraulic fluid.

- Pressure: Confirm the hose can handle the maximum operating pressure.

- Don’t Skimp on Length:

Always add extra length for bends, movement, and vibration. Avoid tight bends that could damage the hose. - Consult the Manufacturer:

If you’re unsure, reach out to the hose manufacturer for guidance. Many provide sizing charts and calculators to make the process easier. - Use Flow Charts and Velocity Calculators:

Check the system’s flow rate and velocity requirements and match them to the appropriate hose size. - Inspect Regularly:

Even with the correct size, wear and tear can impact performance. Regularly inspect your hoses for signs of damage, leaks, or blockages.

How to Match Hose Size to Fittings

Selecting the correct hydraulic hose size is only half the battle. To achieve optimal performance, you need to ensure your hose size matches the fittings properly. Improperly matched hoses and fittings can lead to leakage, pressure loss, or even dangerous system failures. Let’s break it down step by step:

1. Understanding Hose Fitting Terminology

Before we dive into the details, let’s get familiar with some basic terminology when it comes to fittings:

- Hose Ends: These are the specific ends of a hose designed to connect to the fittings. Different hose types have different compatibility with fittings.

- Thread Type: Fittings come with specific threads (e.g., JIC, NPT, BSPP) that need to match the threads of your hose and other hydraulic system components.

- Seat Type: This refers to the sealing surface where the fitting connects to the hose. Common seat types include flat face, cone seat, and O-ring face seal.

2. Verify Hose Inside Diameter (ID) and Fitting Size

The most critical factor is ensuring the hose’s ID matches the fitting size. A mismatch here can cause leaks, reduced flow, or unnecessary stress on the connection.

- How to Check:

- Look at the hose’s dash size (e.g., -04, -08, etc.), which corresponds to the ID in sixteenths of an inch.

- Ensure the fitting size matches this dash size. For instance, a -06 fitting must be used with a -06 hose.

- Why It Matters:

- Undersized fittings restrict flow and can cause turbulence in the system.

- Oversized fittings may not create a proper seal, leading to leaks.

3. Account for Hose Outside Diameter (OD) and Fitting Type

While the ID governs fluid flow, the OD affects the compatibility of the hose with fittings and clamps. The OD includes the hose’s reinforcement and outer covering, so it must be accounted for when selecting fittings.

- Fitting Type:

- Some fittings use crimping to secure the hose, which requires precise OD compatibility.

- Ensure the fitting can accommodate the total OD of your hydraulic hose.

- Pro Tip: Always consult the manufacturer’s specifications to verify the OD range that the fitting can handle.

4. Match the Thread Type and Seat Style

Hydraulic fittings are not one-size-fits-all. They come with various thread types and sealing mechanisms that must align with your hose and the rest of your system.

- Common Thread Types:

- JIC (Joint Industry Council): Common in North America, with a 37° flare.

- NPT (National Pipe Tapered): Tapered thread often used in older systems.

- BSP (British Standard Pipe): Found in European systems with parallel threads.

- Common Seat Styles:

- Flat Face: Seals with a gasket or O-ring.

- Cone Seat: Uses a conical sealing surface to create a tight fit.

- O-Ring Face Seal (ORFS): Excellent for high-pressure systems, sealing with an embedded O-ring.

- Pro Tip: When in doubt, use a thread gauge or consult a professional to determine the correct thread type.

5. Ensure Proper Crimping or Clamping

Most hydraulic hose fittings require the use of crimping or clamps to secure the hose to the fitting. Proper crimping ensures a leak-proof seal and a secure connection.

- Crimping Tips:

- Always use a crimping machine designed for the specific fitting and hose size.

- Check the manufacturer’s crimping chart for precise dimensions.

- Inspect the crimped fitting for uniformity—uneven crimps can compromise the seal.

- Clamping Tips:

- If using clamps instead of crimping, ensure the clamps are tightened evenly and securely around the hose.

- Avoid over-tightening, which could damage the hose or reduce flow.

6. Consider Pressure Ratings

Fittings, like hoses, have pressure ratings. Ensure the fitting’s pressure rating is equal to or greater than the maximum operating pressure of your system.

- Tip for High-Pressure Systems:

- For systems with extremely high pressure, consider using fittings with an O-ring face seal (ORFS) or flareless bite-type connections. These provide superior sealing capabilities.

7. Account for Environmental Factors

The hose and fitting connection must withstand the environment where it will be used. Consider the following:

- Temperature: Ensure both the hose and fitting materials can handle the operating temperature.

- Vibration: Select fittings with robust sealing mechanisms to handle vibration without loosening.

- Corrosion Resistance: In corrosive environments, use fittings made from stainless steel or other corrosion-resistant materials.

8. Use the STAMP Method for Compatibility

We talked about the STAMP method earlier, but let’s recap and apply it to hose fittings:

- Size: Match the hose’s ID and OD with the fitting size.

- Temperature: Verify the fitting material can withstand system temperatures.

- Application: Consider vibration, movement, and pressure requirements.

- Material: Choose fittings made from materials compatible with the hydraulic fluid.

- Pressure: Ensure the fittings can handle the system’s maximum pressure rating.

9. Test the Connection After Assembly

Once you’ve matched and installed the hose and fittings, it’s time to test the connection:

- Pressure Test: Gradually pressurize the system to its maximum operating pressure and check for leaks.

- Inspect for Fit: Ensure the hose is securely attached to the fitting with no movement or looseness.

- Run the System: Operate the hydraulic system under normal conditions and check for pressure drops or flow issues.

Conclusion

Choosing the right hydraulic hose size is a balancing act between flow, pressure, and application. By understanding the basics—like ID, OD, and length—and using tools like flow charts and sizing guides, you can ensure your system runs smoothly and efficiently.

Don’t forget to inspect your hoses regularly and replace them as needed to maintain optimal performance and safety. Got questions or tips about hydraulic hose sizing? Drop a comment below—we’d love to hear from you!

FAQs

Q: What happens if I use a hose that’s too small?

A: A hose that’s too small restricts flow, causing pressure drops, overheating, and reduced system efficiency.

Q: Can I use a larger hose to avoid pressure issues?

A: While larger hoses reduce flow restrictions, they may not fit properly in your system and can lead to inefficiencies if oversized.

Q: How do I calculate the right hose size for my flow rate?

A: Use a hydraulic flow calculator or consult the manufacturer’s sizing charts. Match the desired flow rate to the recommended ID size.

Q: What’s the difference between ID and OD?

A: The ID is the inside diameter, determining fluid flow capacity. The OD is the outside diameter, including the hose’s reinforcement and cover layers.

Q: Do different hydraulic fluids affect hose size selection?

A: Yes, some fluids may require specific hose materials or sizes to handle viscosity, temperature, or chemical compatibility.

Q: Can I use the same size hose for all applications?

A: No, different applications require specific hose sizes based on flow, pressure, and environmental factors.