Hydraulic valves are crucial components in any hydraulic system, used to control the flow and pressure of hydraulic fluid. This guide explores the different types of hydraulic valves, their applications, and the benefits they offer. If you’re new to hydraulic systems or want to improve your current setup, this guide can help you make better decisions.

What Are Hydraulic Valves?

HHydraulic valves regulate the flow and pressure of fluid within a hydraulic system. By directing fluid to different parts of the system, they ensure that machinery operates both efficiently and safely.

Types of Hydraulic Valves

Hydraulic valves are integral components of any hydraulic system, offering various functions such as directing fluid flow, regulating pressure, and controlling fluid flow rates. Here, we discuss the different types of hydraulic valves, how they work, and tips for choosing the right valve for your needs.

Hydraulic Flow Control Valves

Hydraulic flow control valves manage the rate of fluid flow within a hydraulic system. Consequently, proper control of fluid flow is crucial for the efficient operation of machinery.

Types of Flow Control Valves:

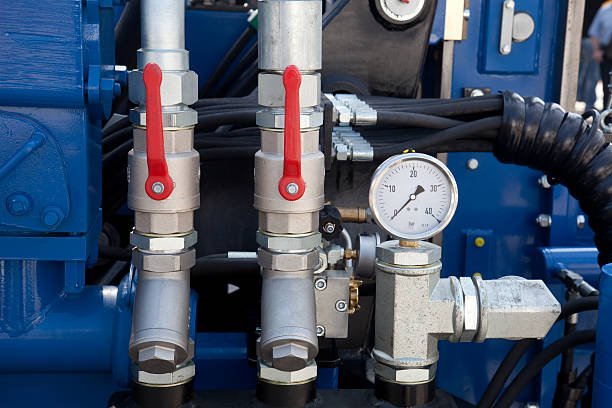

- Ball Valve

- Description: Utilizes a spherical ball to control the flow. Simple, reliable, and suitable for shut-off applications.

- How it works: When the ball with a hole in the center aligns with the flow path, fluid passes through. Rotating the ball 90 degrees blocks the flow.

- Applications: Commonly used in pipeline systems, HVAC systems, and water treatment plants.

- Selection Tips: Choose based on pressure rating, material compatibility, and required size.

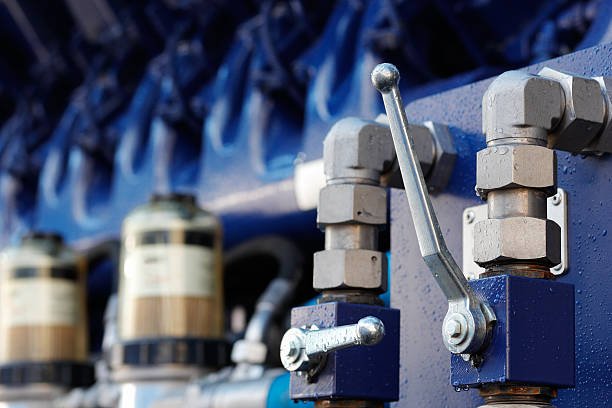

- Plug Valve

- Description: Similar to ball valves but uses a cylindrical or conically tapered plug.

- How it works: The plug is rotated within the valve body to either block or allow flow through the passage.

- Applications: Ideal for chemical processing, oil and gas pipelines, and water distribution.

- Selection Tips: When selecting hydraulic flow control valves, consider the plug material, seal type, and flow control requirements. These factors, in turn, will influence the overall performance and suitability of the valve for your application.

- Needle Valve

- Description: Controls flow precisely with a needle-shaped plunger fitting into a conical seat for accurate control.

- How it works: The needle’s position is adjusted to control the size of the opening, thus regulating flow.

- Applications: Used in instrumentation, hydraulic systems, and gas flow control.

- Selection Tips: Look for precision requirements, pressure ratings, and material compatibility.

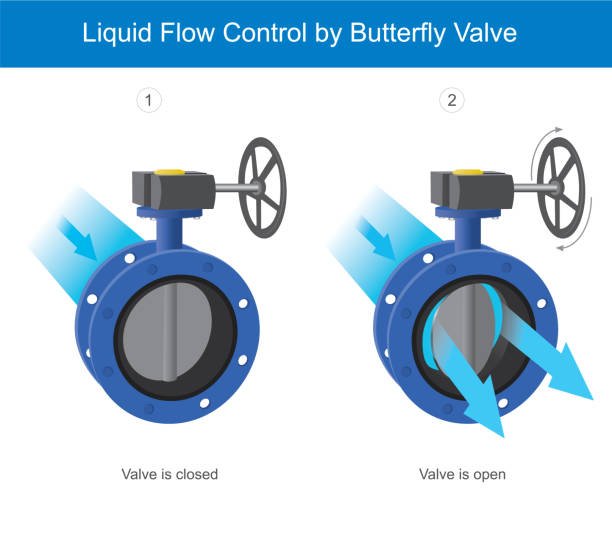

- Butterfly Valve

-

- Description: Uses a rotating disk to regulate flow. It is lightweight and provides quick shut-off.

- How it works: The disk is rotated perpendicular or parallel to the flow to control it.

- Applications: Common in water supply, wastewater treatment, and food processing industries.

- Selection Tips: Ensure you select the appropriate pressure rating, disk material, and ease of operation. By doing so, you will enhance the reliability and efficiency of the hydraulic system.

Fluid Pressure Control Valves

Pressure control valves regulate and maintain the desired pressure within the hydraulic system to ensure safe and efficient operation.

Types of Pressure Control Valves:

Relief Valves

Description: Protect the system from overpressure by releasing excess fluid.

How it works: When system pressure exceeds a set point, the valve opens to release fluid until the pressure drops to a safe level.

Applications: Widely used in hydraulic systems, pipelines, and pressure vessels.

Selection Tips: Choose based on the set pressure, flow rate, and valve material.

Sequence Valves

Description: Ensure operations occur in a specific order by controlling the sequence of fluid flow.

How it works: The valve opens when a predetermined pressure is reached, allowing fluid to flow to the next part of the circuit.

Applications: Commonly used in hydraulic presses, injection molding machines, and construction equipment.

Selection Tips: Select based on the required sequence pressure and flow capacity.

Counterbalance Valves

Description: Maintain a set pressure to balance loads and prevent free fall of loads.

How it works: The valve creates a back pressure to support the load and control its descent.

Applications: Used in lifting and lowering applications, such as cranes and elevators.

Selection Tips: Consider the load capacity, pressure settings, and response time.

Unloading Valves

Description: Divert flow from a pump to the reservoir when system pressure reaches a set level.

How it works: The valve opens at a specified pressure, allowing fluid to bypass the working circuit and return to the tank.

Applications: Essential in hydraulic circuits where pump unloading is required.

Selection Tips: Look for pressure settings, flow capacity, and response accuracy.

Direct Acting Relief Valves

Description: Provide immediate response to pressure changes.

How it works: The valve opens directly in response to overpressure, without any pilot operation.

Applications: Suitable for systems with rapid pressure fluctuations.

Selection Tips: Ensure fast response time, suitable pressure range, and durability.

Pilot-Operated Relief Valves

Description: Offer greater control and efficiency, used for more precise applications.

How it works: The pilot valve controls the main valve, thereby allowing for more accurate pressure control.

Applications: Ideal for complex hydraulic systems requiring fine pressure control.

Selection Tips: Opt for high precision, stability, and adjustable settings.

Pressure Reducing Valves:

- Direct Acting Pressure Relief Valve: Simple and reliable, directly opens to relieve excess pressure.

- Constant and Fixed Pressure Reduction Valves: Maintain a set downstream pressure regardless of changes in upstream pressure.

- Pilot-Operated Relief Valve: Offers stable and precise pressure control, commonly used in complex systems.

Directional Control Valves

Directional control valves direct the flow of fluid to different paths in the hydraulic system, ensuring the correct operation of machinery.

Types of Directional Control Valves:

- Multiway Directional Control Valves

- Description: Multiway directional control valves allow fluid to flow in multiple directions. The most common type of valve is the 2-way valve. It can either permit the fluid to pass or, alternatively, halt it. A water tap is a typical example of this type of valve.

- How it works: The valve directs fluid to different paths within the hydraulic system, enabling various operations.

- Applications: This is used in complex machines with many pathways, such as factory equipment and, additionally, portable devices.

- Selection Tips: Consider the number of flow paths, valve actuation method, and system requirements.

- Check Valve

- Description: Allows fluid to flow in one direction only, preventing backflow.

- How it works: Check valves use a spring or, alternatively, gravity to close when fluid tries to flow in the wrong direction.

- Applications: Commonly used in pumps, compressors, and fluid systems where backflow prevention is critical.

- Selection Tips: Ensure compatibility with the fluid type, pressure ratings, and required flow direction.

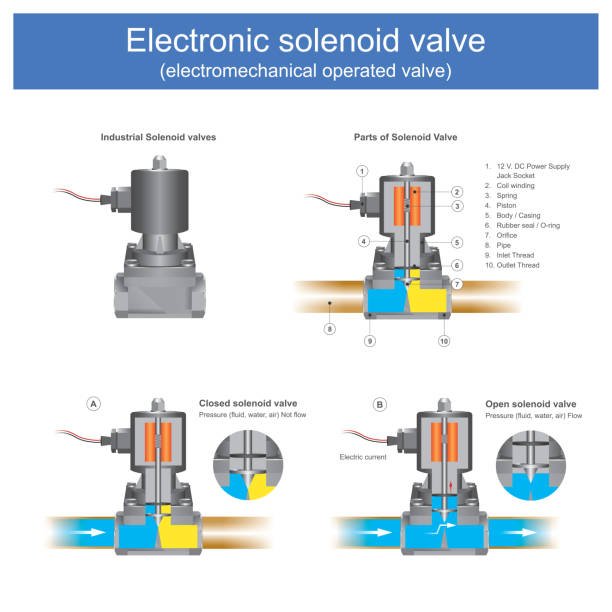

- Solenoid Valve

- Description: Electrically operated valves used for controlling the direction of fluid flow in automated systems.

- How it works: The valve uses an electromagnetic solenoid to open or close the valve, controlling fluid flow.

- Applications: Widely used in industrial automation, manufacturing processes, and HVAC systems.

- Selection Tips: Choose based on electrical specifications, response time, and required flow rate.

Advantages and Disadvantages of Hydraulic Valves

Advantages of Hydraulic Valves

- Precise Control

- Advantage: Hydraulic valves allow for precise control of fluid flow and pressure within a system.

- Explanation: They can handle large loads with minimal energy loss. Consequently, this makes them ideal for heavy machinery and industrial applications.

- High Efficiency

- Advantage: Hydraulic systems, including their valves, are highly efficient at transmitting power.

- Explanation: They can handle large loads with minimal energy loss, making them ideal for heavy machinery and industrial applications.

- Versatility

- Advantage: Hydraulic valves are versatile and can be used in a wide range of applications.

- Explanation: The pilot valve controls the main valve, thus enabling more accurate pressure control.

- Durability and Longevity

- Advantage: High-quality hydraulic valves are durable and can have a long service life.

- Explanation: They are designed to withstand high pressures and harsh environments, reducing the need for frequent replacements.

- Safety

- Advantage: Hydraulic valves can enhance the safety of hydraulic systems.

- Explanation: Features such as pressure relief valves and counterbalance valves help prevent system overpressure and uncontrolled movements, thereby protecting both equipment and operators.

- Smooth Operation

- Advantage: Hydraulic valves provide smooth and steady operation.

- Explanation: This is particularly important in applications where abrupt movements could cause damage or safety issues. For example, this applies to material handling and, furthermore, precision machining.

Disadvantages of Hydraulic Valves

- Complexity

- Disadvantage: Hydraulic systems can be complex and require careful design and maintenance.

- Explanation: The complexity of hydraulic circuits and the need for precise valve settings can make troubleshooting and repairs challenging.

- Maintenance Requirements

- Disadvantage: Hydraulic valves require regular maintenance to ensure optimal performance.

- Explanation: Regular inspections, fluid changes, and component replacements are essential for preventing failures and maintaining efficiency. Consequently, adhering to these practices will help ensure the long-term reliability of the hydraulic system.

- Leakage Issues

- Disadvantage: Hydraulic systems are prone to fluid leaks.

- Explanation: Leaks can occur due to worn seals, damaged components, or improper fittings, leading to reduced efficiency and potential environmental hazards.

- Sensitivity to Contamination

- Disadvantage: Hydraulic systems are sensitive to fluid contamination.

- Explanation: Contaminants such as dirt, water, and metal particles can cause valve blockages, wear, and system failures. Filtration systems are essential to maintain fluid cleanliness.

- Cost

- Disadvantage: High-quality hydraulic valves and systems can be expensive to purchase and install.

- Explanation: The initial cost can be significant, although the long-term benefits and durability may offset these costs.

- Temperature Sensitivity

- Disadvantage: Hydraulic fluid viscosity and valve performance can be affected by temperature changes.

- Explanation: Extreme temperatures can cause fluid thickening or thinning, impacting the efficiency and responsiveness of the valves.

Applications of Hydraulic Valves

Hydraulic valves play a crucial role in various industries by controlling fluid flow and pressure within hydraulic systems. Their versatility and precision, therefore, make them essential components in a wide range of applications. To illustrate, here are some of the primary applications of hydraulic valves across different sectors.

Construction Machinery

- Excavators

- Description: Hydraulic valves control the movement of the arm, bucket, and boom.

- Function: Directional control valves direct fluid to different actuators, enabling precise digging and lifting operations.

- Loaders

- Description: Valves manage the loader arms and buckets.

- Function: Flow control valves ensure smooth lifting and lowering of heavy loads.

- Cranes

- Description: Hydraulic valves are used to control the hoist, jib, and counterweights.

- Function: Pressure control valves maintain stability and prevent overloading.

Industrial Equipment

- Manufacturing Presses

- Description: Valves regulate the movement of press rams.

- Function: Sequence valves ensure operations occur in the correct order, improving safety and efficiency.

- Injection Molding Machines

- Description: Valves control the injection and clamping processes.

- Function: Pressure control valves maintain consistent pressure for high-quality mold production.

- Robotic Arms

- Description: Hydraulic valves manage the precise movements of robotic joints.

- Function: Directional control valves allow for smooth and accurate positioning of the arms.

Agricultural Machinery

- Tractors

- Description: Valves control the hydraulic implements attached to tractors.

- Function: Flow control valves manage the operation of plows, mowers, and loaders.

- Harvesters

- Description: Hydraulic valves are used in the cutting and collection mechanisms.

- Function: Pressure relief valves protect the system from overload during heavy harvesting operations.

- Sprayers

- Description: Valves regulate the flow of pesticides and fertilizers.

- Function: Flow control valves ensure even distribution of chemicals over the crops.

Automotive Industry

- Brake Systems

- Description: Valves control the hydraulic pressure in brake lines.

- Function: Pressure control valves ensure consistent braking force and prevent wheel lockup.

- Power Steering

- Description: Valves manage the flow of hydraulic fluid in the steering system.

- Function: Directional control valves provide smooth and responsive steering assistance.

- Suspension Systems

- Description: Hydraulic valves adjust the damping characteristics of shock absorbers.

- Function: Flow control valves maintain ride comfort and vehicle stability.

Aerospace

- Landing Gear Systems

- Description: Valves control the extension and retraction of landing gear.

- Function: Pressure control valves ensure safe deployment and retraction under varying load conditions.

- Flight Control Systems

- Description: Valves regulate the hydraulic actuators that move control surfaces.

- Function: Directional control valves enable precise adjustments for maneuvering the aircraft.

- Hydraulic Brakes

- Description: Valves manage the braking force applied to the aircraft wheels.

- Function: Pressure relief valves protect the system from excessive pressure during landing.

Marine Industry

- Steering Systems

- Description: Valves control the hydraulic steering mechanisms on ships and boats.

- Function: Directional control valves allow for smooth and precise steering control.

- Deck Machinery

- Description: Hydraulic valves are used in winches, cranes, and other deck equipment.

- Function: Flow control valves ensure the efficient operation of heavy lifting and handling equipment. Specifically, they regulate the flow of fluid, which, in turn, optimizes performance and enhances safety.

- Stabilizers

- Description: Valves regulate the hydraulic stabilizing fins to reduce rolling motion.

- Function: Pressure control valves maintain stability and enhance passenger comfort.

Energy Sector

- Wind Turbines

- Description: Valves control the hydraulic pitch and yaw systems.

- Function: Directional control valves adjust the blade angle to optimize energy capture.

- Oil and Gas Drilling

- Description: Hydraulic valves are used in drilling rigs to control various functions.

- Function: Pressure control valves maintain safe operating pressures during drilling operations.

- Hydraulic Power Units

- Description: Valves regulate the power supply to different parts of the system.

- Function: Flow control valves ensure efficient distribution of hydraulic power.

Key Considerations When Choosing Hydraulic Valves

Selecting the right hydraulic valve for your system is crucial to ensure optimal performance, efficiency, and safety. Here are the key considerations to keep in mind when choosing hydraulic valves:

System Requirements

- Pressure Ratings: Ensure the valve can handle the maximum and minimum pressure levels of your system. Overpressure can lead to valve failure and system damage.

- Flow Rate: Select a valve that fits the needed flow rate to work well without lowering pressure or restricting flow.

- Fluid Type: Consider the type of fluid used in the hydraulic system, which can include oil, water-glycol, or synthetic fluids. The choice of fluid, consequently, can significantly affect valve performance.

Valve Type

- Functionality: Determine the specific function the valve needs to perform (e.g., directional control, pressure control, flow control).

- Operation Method: Decide between manual, electric, pneumatic, or hydraulic actuation based on your system’s requirements and automation level.

Material Compatibility

- Corrosion Resistance: Select valve materials that resist corrosion from the hydraulic fluid and operating environment. Common materials include stainless steel, brass, and various plastics.

- Temperature Tolerance: Ensure the valve materials can withstand the operating temperature range without degradation or loss of performance.

Size and Port Configuration

- Port Size: Match the valve port size to your system’s piping to ensure proper flow and avoid bottlenecks.

- Mounting Configuration: Consider the valve’s mounting requirements (e.g., inline, sub plate, cartridge) to ensure compatibility with your system’s layout.

Performance Characteristics

- Response Time: For applications requiring rapid changes in flow or pressure, choose valves with fast response times to ensure timely and accurate control.

- Leakage: Evaluate the valve’s internal and external leakage rates. Indeed, low-leakage valves are essential for maintaining system efficiency and preventing fluid loss.

Reliability and Durability

- Service Life: Select valves with a proven track record of durability and reliability, especially for critical applications.

- Maintenance Requirements: Consider the ease of maintenance and availability of spare parts to minimize downtime and maintenance costs.

Safety Features

- Pressure Relief: For systems prone to pressure spikes, include pressure relief valves to protect against overpressure conditions.

- Fail-Safe Operation: Choose valves with fail-safe mechanisms like spring return or fail-open/close to ensure safe operation in case of power or system failures.

Compliance and Certifications

- Industry Standards: Ensure the valves comply with relevant industry standards (e.g., ISO, DIN, SAE) for quality and performance assurance.

- Certifications: Look for valves with necessary certifications (e.g., CE, UL) that meet regulatory requirements and industry best practices.

Cost and Availability

- Budget: Balance between cost and quality. While higher-quality valves may have a higher upfront cost, they often provide better performance and longer service life.

- Availability: Consider the lead time and availability of the valves. Reliable supply chains ensure timely replacements and reduce the risk of downtime.

Manufacturer Support

- Technical Support: Choose valves from manufacturers that provide robust technical support and resources. Specifically, look for those that offer installation guides, troubleshooting assistance, and training. This ensures you have the necessary support for effective valve operation and maintenance.

- Warranty and Service: Check the warranty and service offered by the manufacturer for long-term support and reliability.

Maintenance and Troubleshooting of Hydraulic Valves

Regular maintenance and repair of hydraulic valves are crucial for ensuring the longevity of hydraulic systems. Specifically, this maintenance helps keep the systems functioning properly over an extended period.

By consistently maintaining and repairing hydraulic valves, you can ensure that hydraulic systems continue to operate efficiently. Consequently, this maintenance is essential for the long-term performance of these systems. Here, we provide a comprehensive guide to maintaining and troubleshooting hydraulic valves.

Maintenance of Hydraulic Valves

Regular maintenance is crucial to keep hydraulic valves functioning efficiently and to prevent unexpected system failures. Here are the key maintenance practices:

- Regular Inspections

- Visual Inspection: Check for visible signs of wear, damage, or leaks on the valve body, seals, and connections.

- Functional Testing: Ensure the valve operates smoothly without sticking or excessive resistance.

- Cleaning

- External Cleaning: Clean the exterior of the valves to remove dirt, dust, and debris that could interfere with operation.

- Internal Cleaning: Periodically flush the hydraulic system to remove contaminants from within the valves and the system.

- Lubrication

- Proper Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer to reduce friction and wear.

- Avoid Over-Lubrication: Excess lubrication can attract dirt and cause clogging.

- Seal and O-Ring Replacement

- Inspect Seals: Regularly check seals and O-rings for wear, cracks, or damage.

- Timely Replacement: Replace worn or damaged seals and O-rings to prevent leaks and maintain pressure integrity.

- Fluid Maintenance

- Check Fluid Levels: Ensure the hydraulic fluid is at the correct level to avoid cavitation and overheating.

- Fluid Quality: Regularly test the hydraulic fluid for contamination and degradation. Replace fluid as necessary to maintain system performance.

- Preventive Maintenance Schedule

- Establish a Schedule: Develop a preventive maintenance schedule based on the manufacturer’s recommendations and the system’s operating conditions.

- Documentation: Keep detailed records of maintenance activities, including inspections, replacements, and any issues encountered.

Troubleshooting Hydraulic Valves

When issues arise with hydraulic valves, systematic troubleshooting is essential to diagnose and resolve the problem effectively. Here are common issues and troubleshooting steps:

- Valve Sticking or Sluggish Operation

- Cause: Contamination, inadequate lubrication, or mechanical wear.

- Solution: Clean the valve, ensure proper lubrication, and inspect for wear. Replace worn components as needed.

- Leaks

- Cause: Damaged seals, O-rings, or connections.

- Solution: Inspect and replace damaged seals and O-rings. Tighten or replace leaking connections.

- Pressure Drops

- Cause: Internal leakage, clogged filters, or improper valve settings.

- Solution: Check for internal leaks by examining the valve’s components. Clean or replace clogged filters. Verify and adjust valve settings according to specifications.

- Erratic Operation

- Cause: Air in the hydraulic system, electrical issues (for solenoid valves), or incorrect valve settings.

- Solution: Bleed air from the system. Check electrical connections and solenoid operation. Verify and adjust valve settings.

- Noisy Operation

- Cause: Cavitation, air in the system, or worn components.

- Solution: Check for and eliminate air in the system. Inspect for cavitation damage and replace affected components. Ensure proper fluid levels and clean filters.

- Overheating

- Cause: High fluid temperature, excessive load, or inadequate cooling.

- Solution: Ensure proper cooling of the hydraulic system. Reduce load if possible. Check fluid levels and quality.

- Inconsistent Flow or Pressure

- Cause: Blockages, improper valve settings, or wear.

- Solution: Inspect for and remove any blockages. Verify and adjust valve settings. Replace worn components.

Conclusion

Hydraulic valves are vital components that ensure the efficient and safe operation of hydraulic systems. By understanding the different types, applications, and benefits, you can make informed decisions to optimize your hydraulic setup. Whether you’re in construction, manufacturing, agriculture, or any other industry, choosing the right hydraulic valves will enhance your system’s performance and reliability.

For more information on hydraulic valves and other hydraulic components, feel free to visit our website or contact our expert team today. By doing so, you will gain access to valuable insights and support.

FAQs

Q1: What are the main types of hydraulic valves?

A1: The main types of hydraulic valves include directional control valves, pressure control valves, and flow control valves.

Q2: How do hydraulic valves improve system efficiency?

A2: Hydraulic valves enhance system efficiency by providing precise control over fluid flow and pressure, reducing energy consumption.

Q3: What industries use hydraulic valves?

A3: Various industries, such as construction, industrial equipment, agriculture, automotive, aerospace, and robotics, use hydraulic valves.

Q4: What should I consider when choosing a hydraulic valve?

A4: Consider factors such as system requirements, valve type, material compatibility, and quality certifications.

Q5: How can I maintain my hydraulic valves?

A5: Regular inspections, maintaining cleanliness, proper installation, and prompt troubleshooting are key to maintaining hydraulic valves.

Q6: What is the difference between a pilot-operated relief valve and a direct-acting relief valve?

A6: A pilot-operated relief valve offers greater control and efficiency, making it suitable for more precise applications. It utilizes a pilot valve to manage the main valve, thereby allowing for more accurate pressure control. In contrast, a direct-acting relief valve responds quickly to pressure changes without the need for a pilot. Consequently, it performs well in systems with rapid pressure fluctuations.

For any further questions or inquiries, please feel free to reach out to us!