Quality Control

At Taske, we adhere to international standards such as ISO, DIN, and SAE to ensure the high quality and reliability of our hydraulic fittings. Our rigorous quality control system includes meticulous raw material inspection, precise production process control, thorough final inspection, and secure packaging and service. Each step is designed to guarantee the superior performance and durability of our products, providing our customers with reliable hydraulic solutions.

Raw Material Inspection

- Material Selection: Only the highest quality materials.

- Certificates: Each batch has a material test certificate.

- Dimension Checks: 100% dimension checks using calipers.

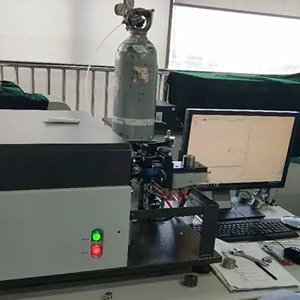

- Chemical Analysis: Random inspection using XRF analyzers and spectrometers.

Production Process Control

- First Article Inspection: Based on drawings, checking dimensions and threads.

- Mass Production: Inspect threads every 10 pieces and dimensions every 15 pieces.

- Consistency: Ensures batch consistency.

Packaging and Service

- Protective Caps: All fittings have plastic caps to prevent scratches.

- Laser Marking: Marking part numbers and traceability codes.

- Free Replacement: 100% free replacement if quality issues are found.

Discuss Your Project Needs

FAQ

Q1: What standards does Taske adhere to for quality control?

A1: We adhere to international standards such as ISO, DIN, and SAE.

Q3: What is involved in the production process control?

A3: Our technicians perform first article inspections, and during mass production, we inspect threads every 10 pieces and dimensions every 15 pieces.

Q5: What packaging and service does Taske provide?

A5: All fittings have protective caps to prevent scratches, laser marking for traceability, and we offer 100% free replacement for quality issues.

Q2: How does Taske ensure raw material quality?

A2: We select high-quality materials, conduct 100% dimension checks, and perform random chemical analysis with XRF analyzers and spectrometers.

Q4: How is the final inspection carried out?

A4: We conduct a 100% visual inspection under strong light, random dimension and angle checks, and thread inspections.

Q6: What certifications does Taske have?

A6: We are ISO 9001:2015 and ISO 14001 certified.