Pressure valves might not be the most glamorous topic, but boy, are they important! These small devices hold the power to maintain safety, protect your equipment, and keep things running smoothly. In this article, we’ll walk you through the ins and outs of reducing pressure valves—how they work, their types, benefits, and even some maintenance tips to keep them in tip-top shape.

So, whether you’re a homeowner, an engineer, or just plain curious, this guide will give you all the answers you need about these mighty components.

What Are Reducing Pressure Valves?

Reducing pressure valves, also known as pressure-reducing valves (PRVs), are devices used to regulate and lower pressure levels within a system. They ensure that the pressure remains within safe limits to prevent damage to pipes, appliances, or industrial equipment.

Think of it like this: Imagine water rushing through your plumbing at high pressure. Without a PRV, that force could damage your pipes or lead to leaks. The valve acts as a “traffic cop,” slowing down the flow to a manageable level.

How Do Reducing Pressure Valves Work?

Here’s the gist:

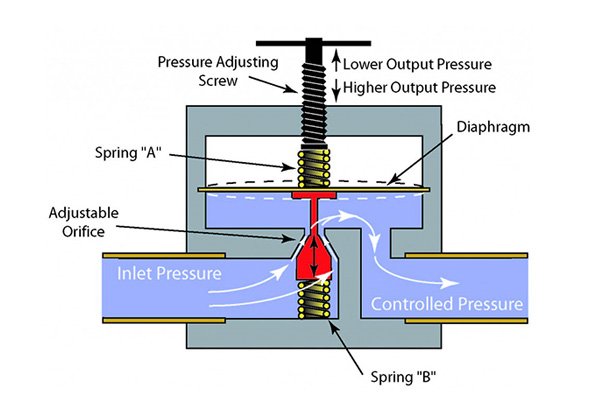

- The valve has an internal mechanism, usually a diaphragm or spring-loaded component, that reduces incoming pressure to a pre-set level.

- When water or gas enters the valve at high pressure, the mechanism adjusts to maintain a steady, lower output pressure.

- As demand changes (e.g., turning on multiple faucets), the valve adapts to ensure consistent flow.

The beauty of reducing pressure valves is their simplicity—yet they’re incredibly effective at maintaining balance and safety in a system.

Benefits of Using Reducing Pressure Valves

Why bother installing one? Let’s break it down:

1. Protects Your System

High pressure can wreak havoc on pipes, appliances, and machinery. PRVs act as a safeguard, extending the lifespan of your equipment.

2. Improves Safety

Excessive pressure isn’t just bad for your equipment—it can be dangerous for people too. PRVs help minimize risks like bursting pipes or system failures.

3. Saves Water and Energy

By maintaining consistent pressure, PRVs reduce water wastage and prevent unnecessary strain on pumps, lowering energy costs.

4. Enhances Performance

Appliances like water heaters or industrial equipment work more efficiently when pressure is properly regulated.

Types of Reducing Pressure Valves

Reducing pressure valves come in a variety of types to suit different applications, environments, and system needs. Choosing the right one is key to ensuring your system operates efficiently and safely. Below, we’ll dive deeper into the most common types, how they function, and where they’re typically used.

1. Direct-Acting Pressure Reducing Valves

- How They Work: Direct-acting valves use a spring mechanism that directly controls the internal diaphragm. As pressure builds, the spring compresses to reduce the pressure before it exits the valve.

- Key Features: Simple design, compact size, and reliable for smaller systems.

- Where They’re Used: Best for low-flow applications, such as residential plumbing, where flow rates aren’t extremely high but pressure control is still essential.

- Pros: Affordable, low-maintenance, and easy to install.

- Cons: Not suitable for high-flow or complex industrial systems due to limited capacity.

2. Pilot-Operated Pressure Reducing Valves

- How They Work: These valves use a two-stage process: a smaller pilot valve adjusts the pressure first, which then controls the main valve to achieve precise pressure regulation.

- Key Features: More advanced and capable of handling high-pressure and high-flow systems with exceptional accuracy.

- Where They’re Used: Industrial systems, power plants, oil and gas pipelines, and other heavy-duty applications that demand precise control.

- Pros: Offers greater sensitivity and control over pressure adjustments; ideal for high-flow situations.

- Cons: Larger in size, more expensive, and requires professional installation and maintenance.

3. Pressure Regulating Valves for Water Systems

- How They Work: Specifically designed to manage water pressure, these valves help ensure consistent water flow while protecting pipes, fixtures, and appliances from excessive pressure.

- Key Features: Optimized for residential and commercial water supply systems. Some models include adjustable settings for custom pressure control.

- Where They’re Used: Plumbing systems in homes, offices, and apartment complexes where municipal water pressure tends to fluctuate.

- Pros: Keeps water systems safe and reduces water waste caused by leaks or bursts.

- Cons: Limited to water applications and may not handle extremely high pressures.

4. Steam Pressure Reducing Valves

- How They Work: Steam PRVs are built to reduce steam pressure in systems where high-temperature steam is used for heating, sterilization, or industrial processes. They operate by throttling the steam flow to a desired lower pressure.

- Key Features: Designed to withstand extreme temperatures and pressures. Many include additional safety features like pressure relief mechanisms.

- Where They’re Used: Industrial steam systems, hospitals, laundries, and manufacturing plants where steam energy powers equipment or heating processes.

- Pros: Highly durable and tailored for steam systems; ensures safety and energy efficiency.

- Cons: Expensive compared to water or gas PRVs and requires specialized knowledge for installation and maintenance.

5. Combination Pressure Reducing Valves

- How They Work: These multifunctional valves combine pressure reduction with additional features, such as backflow prevention or temperature regulation, offering a complete solution for complex systems.

- Key Features: Combines multiple functions in one valve, making it space-saving and efficient.

- Where They’re Used: HVAC systems, commercial plumbing setups, and industries where compact, multi-purpose solutions are required.

- Pros: Saves space and reduces the need for additional components; simplifies system design.

- Cons: Higher upfront cost and more complex to service due to the integration of multiple functions.

6. Gas Pressure Reducing Valves

- How They Work: These valves regulate the pressure of gases like natural gas, compressed air, or industrial gases, ensuring a steady and safe supply.

- Key Features: Engineered for gas applications with a focus on safety and precise pressure control.

- Where They’re Used: Gas pipelines, compressed air systems, and industrial gas processing setups.

- Pros: Highly specialized for gas control; prevents dangerous pressure build-up in gas systems.

- Cons: Specific to gas systems and not usable for liquids or steam applications.

7. Differential Pressure Reducing Valves

- How They Work: These valves maintain a constant pressure difference between two points in a system. They’re particularly useful for balancing pressure in complex systems.

- Key Features: Ensures equal distribution of pressure across components in a system.

- Where They’re Used: HVAC systems and industrial processes where consistent pressure balance is critical for efficiency.

- Pros: Improves energy efficiency and system performance.

- Cons: Requires careful calibration to work effectively.

8. High-Pressure Reducing Valves

- How They Work: Built to handle extremely high incoming pressures, these valves bring pressure down to manageable levels without compromising system performance.

- Key Features: Heavy-duty construction with reinforced materials to handle extreme pressures.

- Where They’re Used: Oil and gas industries, chemical processing plants, and other systems that operate at very high pressures.

- Pros: Designed for durability and reliability in demanding environments.

- Cons: Expensive and requires professional maintenance.

Which Type Should You Choose?

Choosing the right type of pressure-reducing valve depends on your system’s specific needs. For example:

- For home use: A direct-acting or water pressure regulating valve will usually suffice.

- For industrial setups: Pilot-operated or steam pressure reducing valves may be more appropriate.

- For gas systems: Opt for specialized gas pressure reducing valves.

Take the time to evaluate your requirements, and don’t hesitate to consult with a professional to ensure you select the most suitable valve for your application.

Where Are Reducing Pressure Valves Used?

You’ll find PRVs in all kinds of places, such as:

- Residential Plumbing: To maintain safe water pressure for homes.

- Industrial Systems: To regulate pressure in manufacturing or processing plants.

- HVAC Systems: To control pressure in heating and cooling systems.

- Irrigation Systems: To prevent overwatering and protect sprinkler heads.

How to Maintain Reducing Pressure Valves

Like any other component, reducing pressure valves need a little TLC to stay effective. Here’s what you can do:

1. Regular Inspections

Check for leaks, corrosion, or any unusual sounds. Early detection can save you a lot of trouble.

2. Clean the Valve

Sediment buildup can reduce efficiency. Flush the valve occasionally to remove debris.

3. Test the Pressure

Use a pressure gauge to ensure the valve is maintaining the correct pressure. If it’s off, it might need adjustment or replacement.

4. Schedule Professional Maintenance

For complex systems, it’s wise to bring in a professional to inspect and calibrate the valve annually.

Signs Your Reducing Pressure Valve Needs Replacement

Even with regular maintenance, PRVs can wear out over time. Here are some red flags to watch for:

- Inconsistent pressure (too high or too low).

- Frequent leaks or drips from the valve.

- Strange noises like banging or whistling in the pipes.

- Visible signs of rust or corrosion.

If you spot any of these issues, it’s time to consider a replacement.

Conclusion

Reducing pressure valves may not be the flashiest part of your system, but they’re undoubtedly one of the most important. They keep your equipment safe, improve performance, and save you money on repairs and energy costs. By understanding how they work and keeping up with maintenance, you can ensure your system operates smoothly for years to come.

So, next time you hear that reassuring hiss of pressure being regulated, remember—you’ve got a small but mighty hero working behind the scenes!

FAQs

1. Do I really need a pressure-reducing valve in my home?

Yes, if your home experiences high water pressure, a PRV can prevent damage to pipes and appliances, saving you money in the long run.

2. How do I know what pressure my system needs?

Most residential systems operate at 40-60 psi. Consult a professional or check your system’s specifications for exact requirements.

3. Are PRVs expensive to install?

The cost depends on the type and size of the valve, but for most homeowners, it’s an affordable investment compared to potential repair costs.

4. Can I adjust a PRV myself?

Yes, many valves allow you to adjust the pressure using a screw or knob. However, it’s best to consult the user manual or a professional to avoid mistakes.