1. Introduction

Reusable Fittings Reduce Industrial Waste by providing a practical, sustainable alternative to traditional single-use components. In modern manufacturing, every small design choice can have a massive impact on the environment — and fittings are no exception. These often-overlooked connectors play a critical role in fluid, gas, and mechanical systems, and when designed for reuse, they help industries minimize waste, cut costs, and conserve resources.

Industrial waste remains one of the biggest challenges facing global production today. From discarded metal parts and worn-out plastic connectors to chemical byproducts, industries generate billions of tons of waste each year. This not only strains landfills and ecosystems but also increases operating expenses. By adopting reusable fittings, companies can extend the lifespan of essential components, dramatically reduce waste generation, and move closer to a truly circular manufacturing model that supports environmental sustainability and economic efficiency.

2. Understanding Industrial Waste

Industrial waste encompasses all materials that are byproducts of manufacturing and production processes. These can include:

- Metal shavings, machining fluids, and slag from heavy industries

- Plastic and rubber residues from packaging and assembly operations

- Chemical and solvent wastes from cleaning and processing systems

- Discarded fittings, fasteners, and piping components

According to the World Bank, industrial activities account for approximately 18 billion tons of waste annually, much of which is non-biodegradable. The Environmental Protection Agency (EPA) reports that a significant portion of this waste comes from machinery maintenance and equipment replacements, where single-use parts like couplings, fittings, and seals are routinely discarded.

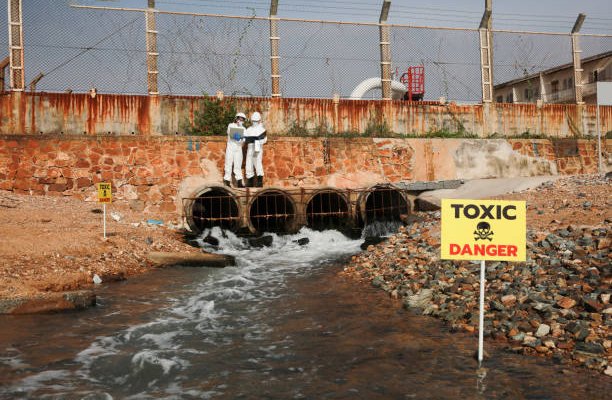

This problem extends beyond environmental damage. Improper disposal can lead to:

- Water contamination due to leaching of heavy metals or lubricants

- Soil degradation from industrial chemicals

- Air pollution caused by incineration of plastic and rubber components

Reusable fittings address these issues at their source. By replacing single-use fittings with components that can be repeatedly utilized, industries can reduce the volume of waste produced and minimize the need for raw material extraction.

Furthermore, industrial waste management is a major cost burden. Businesses must pay for the collection, transport, treatment, and disposal of their waste. Reducing waste at the production stage — through durable, reusable components — leads to direct financial savings and compliance with tightening environmental regulations such as ISO 14001 and the EU Waste Framework Directive.

3. The Concept of Reusable Fittings in Modern Industries

Reusable fittings are engineered to deliver consistent performance over multiple assembly and disassembly cycles. Unlike crimped or welded fittings that must be cut off and replaced when damaged, reusable types can be reinstalled without compromising their integrity.

These fittings typically feature:

- Threaded or compression mechanisms for easy attachment and removal

- Replaceable seals and ferrules to maintain leak-proof performance

- High-grade materials like stainless steel, brass, or aluminum

- Corrosion-resistant coatings for extended use in harsh environments

How They Work

Reusable fittings are used in systems where fluid or gas transfer occurs under varying pressures. For example, in hydraulic systems, hoses are connected to pumps and cylinders using these fittings. When maintenance is required, technicians can detach the fitting, inspect or replace internal seals, and reinstall it — eliminating the need for a brand-new connector.

Key Advantages

- Longevity – They can last several years, compared to months for single-use fittings.

- Reduced Downtime – Quick assembly and disassembly minimize production halts.

- Lower Waste Output – Each fitting reused prevents another from entering the waste stream.

- Enhanced Safety – Properly maintained reusable fittings ensure leak-free operation, reducing workplace hazards.

Industry Adoption Examples

- Automotive manufacturing uses reusable hydraulic fittings to power assembly-line robotics.

- Oil & gas operations rely on corrosion-resistant fittings for high-pressure applications.

- Food and beverage processing plants utilize hygienic, reusable fittings that meet FDA and NSF standards, ensuring both safety and sustainability.

Reusable fittings embody the shift toward a circular economy — where materials remain in circulation as long as possible, maximizing value while minimizing waste.

4. Impact of Single-Use Industrial Fittings

The use of single-use fittings is a legacy practice that originated from an era when production efficiency and cost reduction were prioritized over sustainability. While disposable fittings initially seem convenient — easy to install, cheaper upfront, and quickly replaceable — their environmental impact has proven to be substantial and far-reaching.

Resource Depletion and Material Waste

Each single-use fitting typically contains metals such as carbon steel, aluminum, brass, or plastic polymers. The mining, smelting, and refining processes required to produce these materials are energy-intensive and carbon-heavy.

According to the International Energy Agency (IEA), the metal manufacturing industry alone accounts for nearly 8% of global CO₂ emissions. When fittings are discarded after one use, the energy and resources that went into their creation are effectively wasted.

In high-demand industries — such as oil extraction, automotive manufacturing, and heavy construction — fittings are often replaced after short usage cycles. This practice generates thousands of tons of scrap metal annually. Since not all fittings are recyclable due to mixed materials and coatings, a large portion ends up in industrial landfills or metal recovery facilities, both of which add to the waste management burden.

Pollution from Manufacturing and Disposal Processes

The lifecycle of a single-use fitting contributes to pollution at multiple stages:

- Manufacturing Stage: Factories emit greenhouse gases, sulfur dioxide, and chemical effluents during metal and polymer processing.

- Transportation Stage: Shipping fittings from manufacturing sites to end-users consumes fossil fuels, contributing to further carbon emissions.

- Disposal Stage: When disposed of improperly, fittings can leach harmful substances such as chromium, nickel, or zinc into soil and groundwater.

Moreover, plastic fittings — common in low-pressure pneumatic systems — are particularly problematic. They degrade slowly, releasing microplastics into the environment. These microplastics can contaminate soil, rivers, and even enter the food chain.

A Systemic Issue

When you multiply this waste generation across thousands of factories globally, the scale of the environmental issue becomes evident. The United Nations Industrial Development Organization (UNIDO) estimates that reducing waste through component reuse could cut global industrial emissions by up to 30%. Reusable fittings, therefore, offer a direct and measurable solution to mitigate these negative environmental impacts.

5. How Reusable Fittings Contribute to Waste Reduction

Switching from single-use to reusable fittings is not just a change in product preference; rather, it represents a transformation in how industries manage their materials lifecycle. In fact, reusable fittings offer multiple layers of environmental benefits because they not only cut down waste generation but also minimize energy use. As a result, they strongly support more sustainable manufacturing systems across various industries.

Extended Lifespan and Reusability Benefits

Reusable fittings are designed for durability and modularity. Unlike crimped fittings that must be destroyed during disassembly, reusable fittings feature threaded ends and replaceable seals that allow them to be taken apart and reassembled many times.

This design significantly extends their service life. In some industrial applications, reusable fittings can be used up to 10 times longer than their single-use counterparts. By doing so, the demand for new fittings drops, conserving both materials and manufacturing energy.

Reduction of Scrap Metal and Plastic Waste

Every fitting that’s reused eliminates one from being discarded. When this practice is scaled across a large production network, the cumulative reduction in waste is massive.

For instance, if a manufacturing plant that consumes 50,000 fittings per year converts half of them to reusable fittings, it can prevent over 25 tons of scrap metal from entering the waste stream annually.

Additionally, reusable fittings typically use higher-quality alloys or engineered plastics that can be refurbished or recycled at the end of their lifecycle — further minimizing landfill waste.

Supporting Circular Economy Practices

Reusable fittings exemplify circular economy principles, where the goal is to keep materials and products in use for as long as possible. Here’s how they fit into that cycle:

| Circular Economy Stage | Role of Reusable Fittings |

|---|---|

| Design | Created for multiple reuse cycles and easy maintenance |

| Production | Made from recyclable, durable materials |

| Use | Can be cleaned, resealed, and reinstalled |

| Reuse/Repair | Modular design allows part replacement without full disposal |

| Recycle | End-of-life fittings can be melted down for new production |

By integrating reusable fittings into their operations, companies reduce raw material consumption, energy demand, and waste generation — all key performance indicators (KPIs) in sustainable manufacturing.

Environmental Impact Metrics

Studies from the European Industrial Ecology Institute show that adopting reusable fittings can:

- Reduce industrial landfill waste by 35–50%

- Lower carbon emissions by 20–30% over a 5-year operational cycle

- Conserve up to 40% of materials used in fitting production

These measurable benefits not only improve sustainability scores but also support compliance with ESG (Environmental, Social, and Governance) reporting standards increasingly demanded by investors and regulators.

6. Advantages of Reusable Fittings

While environmental benefits are often the main motivator for adopting reusable fittings, the economic advantages are equally compelling. Companies that invest in reusable systems often see returns within the first few years due to reduced replacement costs, minimized downtime, and lower waste management expenses.

Lower Operational and Maintenance Costs

Reusable fittings require a higher upfront investment compared to disposable ones, but they quickly pay for themselves through reduced maintenance cycles. Because they can be disassembled, cleaned, and reused, industries save significantly on replacement labor and downtime.

For example, in hydraulic systems where fittings experience extreme pressure, a single replacement can take hours of maintenance work. With reusable fittings, the technician can simply replace the seal or reassemble the existing fitting, reducing maintenance time by up to 50%.

Reduced Procurement and Disposal Expenses

Fewer purchases and less waste mean smaller procurement budgets and lower disposal fees. Waste management costs — including collection, sorting, and transport — can account for up to 10% of operational budgets in large manufacturing facilities.

Reusable fittings directly cut this expense by reducing the volume of waste sent to landfills.

Enhanced Supply Chain Efficiency

Reusable fittings also improve supply chain stability. Since they have longer replacement cycles, companies face fewer disruptions caused by parts shortages or delayed shipments.

This stability is particularly beneficial during global supply chain crises — such as those seen during the COVID-19 pandemic — when manufacturing delays made it difficult to source specialized components.

Long-Term ROI (Return on Investment)

When analyzed over a 5-year period, industries that transition to reusable fittings report average cost savings of 20–40%, depending on the application. These savings come from reduced procurement, waste disposal, and maintenance costs, combined with longer product lifespans.

Bonus: Competitive Advantage

In a business landscape increasingly defined by sustainability goals, adopting reusable fittings can significantly enhance a company’s brand reputation while also positioning it as a leader in eco-friendly innovation. Consequently, this approach can attract more eco-conscious clients and, in turn, open new markets that prioritize sustainable supply chains.

7. Types of Reusable Fittings Used in Various Industries

Reusable fittings are not one-size-fits-all solutions. They come in a variety of types, materials, and configurations, each designed to handle specific pressures, temperatures, and fluid compatibility requirements. Understanding these categories helps industries choose the most effective fitting for their applications while maximizing reusability.

Hydraulic and Pneumatic Fittings

Hydraulic and pneumatic systems are the backbone of modern industry — powering everything from construction equipment and assembly lines to automated packaging machines. These systems depend on fittings that can handle high pressure, prevent leaks, and be easily serviced.

- Hydraulic Reusable Fittings:

Made from stainless steel or carbon steel, these fittings are designed for high-pressure applications (often exceeding 10,000 PSI). They connect hoses to hydraulic pumps, valves, and actuators. The main advantage is that the fitting can be removed and reused when a hose needs replacement, saving time and material waste. - Pneumatic Reusable Fittings:

Used in compressed air systems, pneumatic fittings are typically lighter and often made from brass or reinforced polymers. Their quick-connect designs allow for rapid assembly/disassembly, which is ideal in facilities requiring frequent equipment reconfiguration.

Stainless Steel and Brass Fittings

Material selection is crucial for ensuring durability and reusability:

- Stainless Steel Fittings: Corrosion-resistant and suitable for harsh environments like marine, chemical, and oil sectors. They can withstand both corrosive chemicals and high-temperature exposure.

- Brass Fittings: Commonly used in plumbing and fluid transfer systems due to their excellent machinability and leak-resistant sealing properties. They maintain structural integrity even after multiple uses.

Quick-Connect and Modular Fittings

Quick-connect fittings are widely used in food processing, pharmaceutical, and semiconductor industries, where downtime must be minimized. These fittings use a simple push-and-lock or twist mechanism, making them reusable and ideal for applications that require frequent cleaning or line changes.

- Modular Fittings:

These are modern innovations designed for scalability. Modular fittings can be rearranged into different configurations, supporting the flexibility needed in custom manufacturing systems and automation environments.

| Type of Reusable Fitting | Industry Example | Reusable Feature | Typical Lifespan |

|---|---|---|---|

| Hydraulic Fittings | Construction, Manufacturing | Threaded reassembly | 10+ years |

| Pneumatic Fittings | Packaging, Automation | Quick-connect system | 7–10 years |

| Stainless Steel Fittings | Oil & Gas, Marine | Corrosion-resistant design | 15+ years |

| Brass Fittings | HVAC, Plumbing | Leak-proof sealing | 8–12 years |

| Modular Fittings | Robotics, Automotive | Reconfigurable design | 10+ years |

These variations ensure that industries can adopt reusable fittings without compromising operational performance or safety, regardless of the application.

8. Reusable Fittings and Sustainability Standards

The adoption of reusable fittings aligns directly with a range of international sustainability and environmental management frameworks. Companies striving to achieve net-zero goals and green certification find reusable components integral to their strategy.

Compliance with ISO 14001 and Green Manufacturing Protocols

ISO 14001, the global standard for environmental management systems (EMS), emphasizes waste minimization and continuous improvement in sustainability performance. By integrating reusable fittings:

- Companies reduce their environmental impact through lower waste output.

- Manufacturing facilities can document measurable progress in resource efficiency.

- They achieve better compliance with environmental audits and corporate governance requirements.

Reusable fittings also complement Lean Manufacturing and Green Production principles, which prioritize elimination of waste (muda) and value retention throughout the production cycle.

Contribution to Corporate Social Responsibility (CSR) and ESG Goals

Modern investors and consumers are placing increasing value on ESG (Environmental, Social, and Governance) performance. Businesses that utilize reusable fittings can demonstrate:

- Environmental stewardship through material reuse

- Economic efficiency via cost savings and resource conservation

- Governance transparency by reporting measurable sustainability metrics

In many industries, the shift to reusable fittings has become part of CSR initiatives, helping companies strengthen their brand image while fulfilling ethical obligations to the environment.

Certification and Reporting Benefits

Adopting reusable fittings contributes to eligibility for several green certifications:

- LEED (Leadership in Energy and Environmental Design) for sustainable facilities

- BREEAM for eco-efficient building operations

- EPA’s WasteWise Recognition Program for waste reduction achievements

These certifications not only validate sustainability efforts but also offer tax incentives and market advantages, particularly for companies exporting to regions with stringent environmental requirements, such as the European Union’s Green Deal framework.

Conclusion

The global industrial landscape is evolving — and reusable fittings are at the forefront of this sustainable revolution. What was once a small mechanical component has now become a symbol of efficiency, responsibility, and innovation.

By embracing reusable fittings, industries can achieve:

- Significant reductions in waste and emissions

- Substantial long-term cost savings

- Improved system reliability and flexibility

- Compliance with global sustainability standards

More importantly, reusable fittings reflect a mindset shift — from linear “take-make-dispose” production to a circular, regenerative model where resources are valued and preserved.

Every fitting reused is a step closer to a cleaner planet and a more efficient industry. Whether it’s a food processing facility adopting stainless steel connectors or an oil rig reusing high-pressure couplings, these small changes collectively create a massive environmental impact.

As industries move toward 2030 sustainability goals and beyond, the adoption of reusable fittings is not just an option — it’s a necessity for building a resilient, waste-free future.

FAQs

Q1. What exactly are reusable fittings?

Reusable fittings are mechanical connectors that can be assembled, disassembled, and reused multiple times without losing functionality. They’re designed for systems that transfer fluids or gases, such as hydraulic and pneumatic lines.

Q2. How do reusable fittings help reduce industrial waste?

By eliminating the need for constant replacements, reusable fittings prevent tons of metal and plastic waste from entering landfills. They also lower demand for raw materials and reduce manufacturing energy consumption.

Q3. Are reusable fittings more expensive than single-use ones?

Initially, yes — typically 20–30% higher in cost. However, they last far longer and save money in the long run through reduced maintenance, replacement, and disposal costs.

Q4. Can reusable fittings be used in high-pressure systems?

Absolutely. Many are specifically designed for high-pressure hydraulic and pneumatic systems, often rated for pressures above 10,000 PSI, depending on the material and design.

Q5. What materials are used in reusable fittings?

Common materials include stainless steel, brass, carbon steel, and high-performance polymers. These materials are chosen for their strength, corrosion resistance, and ability to maintain seals over multiple uses.

Q6. How can a company transition to reusable fittings effectively?

Start with a pilot project to test performance, provide employee training, and standardize fitting specifications across departments. Partnering with sustainable suppliers and tracking environmental metrics will also ease the transition.