Ferrule fittings play a crucial role in ensuring leak-proof connections in fluid and gas systems. Whether in industrial pipelines or domestic plumbing, these fittings are designed to create secure, durable connections between tubes, pipes, and hoses, making them indispensable across various applications. Typically comprising a nut, a ferrule (a metal ring), and a body, ferrule fittings work by compressing the ferrule around the tubing to create a tight seal. This reliable sealing mechanism makes ferrule fittings indispensable in various industries where precise and durable connections are critical.

What is a Ferrule Fitting?

A ferrule fitting is a type of compression fitting that uses a ferrule to create a tight seal between the tubing and the fitting body, ensuring a leak-proof connection. The ferrule, typically a metal ring, is compressed against the tubing as the fitting’s nut is tightened, deforming the ferrule to grip the tubing securely and prevent leaks. Ferrule fittings are widely used for their simplicity, effectiveness, and ability to maintain system integrity under challenging conditions.

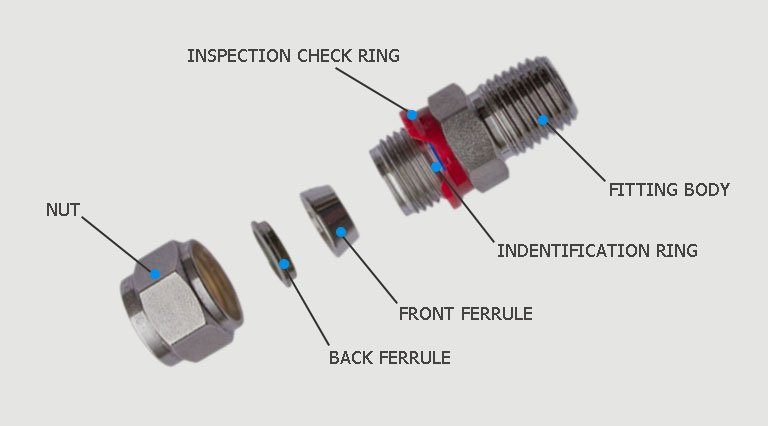

Components of Ferrule Fittings

Ferrule fittings are composed of three main components:

- Nut: The nut is the outer component that, when tightened, compresses the ferrule against the tubing and the fitting body.

- Ferrule: The ferrule is the key component that forms the seal. As the nut is tightened, the ferrule deforms and grips the tubing, creating a leak-proof connection.

- Body: The body of the fitting provides the structure to which the tubing is connected. It typically has a threaded section for the nut and an internal bore for the tubing to be inserted.

These components are made from various materials, including stainless steel, brass, and plastic, depending on the application requirements.

Where Are Ferrule Fittings Used?

Industrial Applications

They are extensively used in industries such as:

- Oil and Gas: For pipelines, instrumentation, and control systems that require high-pressure and corrosion-resistant connections.

- Chemical Processing: Where compatibility with aggressive chemicals and high-temperature environments is essential.

- Pharmaceuticals: In sterile environments where leak-proof and contamination-free connections are critical.

Domestic Applications

They are also found in domestic settings, particularly in plumbing and HVAC systems, where they provide reliable and easy-to-install connections.

Specialized Uses in Various Sectors

In addition to industrial and domestic uses, they are employed in specialized sectors such as:

- Aerospace: For systems that require lightweight yet durable fittings.

- Laboratory Equipment: Where precise control over fluids and gases is necessary.

Types of Ferrule Fittings

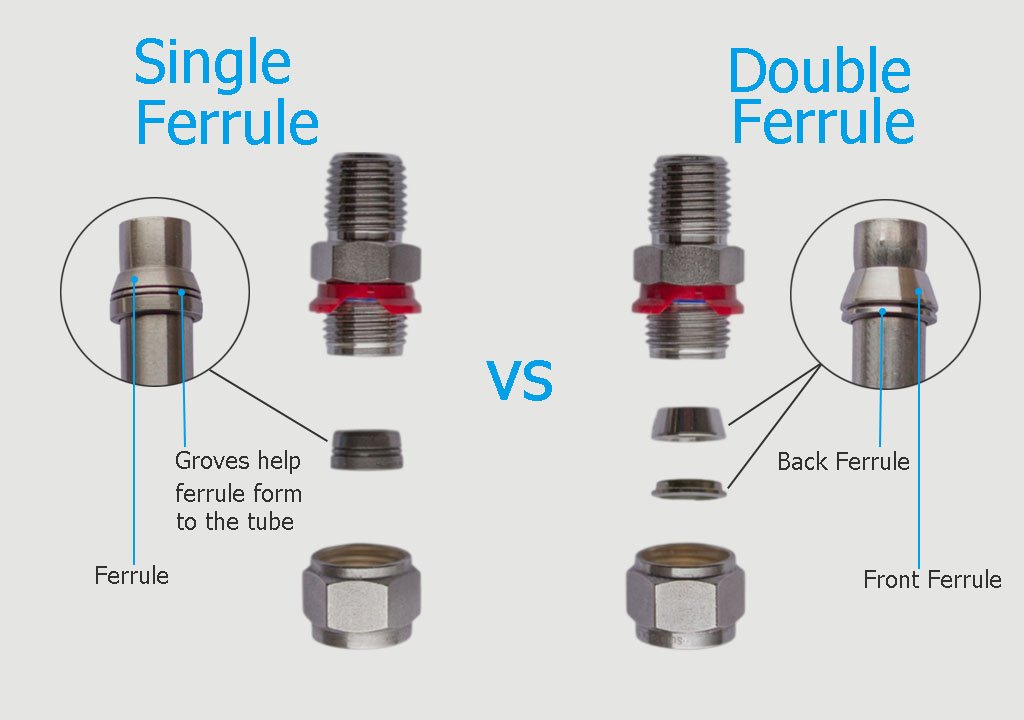

Single Ferrule Fittings

Single ferrule fittings use one ferrule to secure the tubing within the fitting body. This design is straightforward and often more cost-effective, making it suitable for applications where extreme sealing performance is not critical but reliability is still required.

Double Ferrule Fittings

Double ferrule fittings incorporate two ferrules—a front ferrule that grips the tubing and a back ferrule that supports and aligns the tubing. This design provides a higher level of sealing integrity, especially in high-pressure and high-temperature applications, making double ferrule fittings the preferred choice in more demanding environments.

Comparison Between Single and Double Ferrule Fittings

Single ferrule fittings are generally easier to install and less expensive, making them ideal for less demanding applications. Double ferrule fittings, though more complex and slightly more costly, offer superior performance in critical applications where system reliability is paramount.

How Ferrule Fittings Work

Mechanism of Action

Ferrule fittings operate by compressing the ferrule between the fitting body and the tubing. As the nut is tightened, the ferrule deforms, creating a tight grip on the tubing and forming a seal that prevents leaks. This simple yet effective mechanism is what makes it highly reliable across various applications.

The Role of Compression in Sealing

Compression is the core principle behind ferrule fittings. The act of tightening the nut causes the ferrule to compress and grip the tubing, ensuring that the connection remains leak-proof even under high pressure and temperature conditions.

Common Misconceptions

A common misconception is they are difficult to install and prone to leaks. In reality, when installed correctly according to manufacturer guidelines, They provide long-lasting, reliable connections. Another misconception is that it suits only metal tubing, but they can also work with various materials, including plastics and composites.

How Do You Install a Ferrule on Tubing?

Tools Required for Installation

To install it, you will need the following tools:

- A wrench for tightening the nut.

- A tube cutter to prepare the tubing.

- A deburring tool to smooth the cut edges of the tubing.

Step-by-Step Installation Guide

- Cut the Tubing: Use a tube cutter to cut the tubing to the desired length, ensuring a clean, square cut.

- Deburr the Tubing: Smooth the cut end of the tubing using a deburring tool to remove any sharp edges.

- Insert the Tubing into the Fitting: Slide the nut and ferrule onto the tubing, then insert the tubing into the fitting body until it bottoms out.

- Tighten the Nut: Tighten the nut by hand until finger-tight, then use a wrench to turn the nut an additional specified number of turns as per the manufacturer’s instructions.

- Check for Leaks: After installation, pressurize the system and check for any signs of leakage around the fitting.

Common Installation Mistakes and How to Avoid Them

Common mistakes include over-tightening the nut, which can deform the ferrule and cause leaks, and failing to deburr the tubing, leading to poor sealing. Following the manufacturer’s instructions and using the correct tools can help avoid these issues.

What is the Point of a Ferrule?

Role of the Ferrule in Sealing

The primary function of the ferrule is to create a secure seal between the tubing and the fitting body. As the nut is tightened, the ferrule compresses and deforms, gripping the tubing and sealing the connection to prevent leaks.

Ensuring Leak-Proof Connections

Ferrules ensure leak-proof connections even under high pressure, high temperature, and corrosive conditions. The quality of the ferrule directly impacts the reliability and durability of the connection.

Durability and Longevity of the Connection

A well-installed ferrule fitting can last for many years without failure if you use suitable materials and maintain it properly. The ferrule’s ability to maintain a secure seal over time is what makes it so valuable in critical applications.

Comparing Ferrule Fitting to Other Connection Methods

Ferrule Fittings vs. Flare Fittings

Flare fittings use a flared end of the tubing to create a seal, which is a reliable method but can be more complex to install than ferrule fittings. They are generally easier to install and offer better performance under high-pressure conditions.

Ferrule Fittings vs. Push-to-Connect Fittings

Push-to-connect fittings install quickly and easily, but they are best for lower pressure applications. Ferrule fittings, which require more installation effort, seal better and are suited for high-pressure and critical applications.

Advantages Over Other Methods

Ferrule fittings offer several advantages over other connection methods, including higher pressure handling, better corrosion resistance, and a more secure seal. These advantages make them the preferred choice for applications where reliability and performance are critical.

Advantages of Using Ferrule Fittings

High Pressure Handling

Ferrule fittings can withstand high pressures, making them ideal for applications where connection integrity is critical, such as in oil and gas pipelines.

Corrosion Resistance

Materials like stainless steel and brass provide excellent corrosion resistance, ensuring the long-term durability in harsh environments.

Ease of Installation and Maintenance

Despite the precision required for installation, they are relatively easy to install and maintain compared to other types of fittings that may require welding or threading.

Versatility in Applications

You can use it in a wide range of applications, from industrial systems to domestic plumbing, thanks to their compatibility with various materials and fluids.

Importance of Quality

Ensuring Reliable Performance

The quality is crucial for ensuring reliable performance, especially in critical applications where system failure is not an option.

Compliance with Industry Standards

Manufacturers design and produce high-quality ones to meet industry standards, ensuring reliable performance under various conditions.

Avoiding Failures in Critical Applications

Using substandard ones can lead to system failures, leaks, and even safety hazards, making it essential to choose fittings from reputable manufacturers.

Choosing the Right Ferrule Fitting for Your Needs

Factors to Consider

Consider factors like material compatibility, pressure and temperature requirements, the type of fluid or gas being transported, and specific application needs.

Application-Specific Recommendations

For high-pressure applications, double ferrule fittings made from stainless steel are often recommended. In contrast, for less demanding applications, single ferrule fittings made from brass may suffice.

Consulting with Experts and Manufacturers

Consulting with experts or reputable manufacturers can help ensure you select the right one for your specific needs, taking into account all relevant factors to optimize performance and reliability.

Maintenance and Troubleshooting

Regular Maintenance Practices

Regular inspection is important to ensure they remain leak-proof and function correctly. This includes checking for signs of wear, corrosion, or loosening over time.

Troubleshooting Common Issues

Leaks are common issues, and can often be resolved by retightening the fitting. Tubing slippage may also occur, requiring reinstallation or replacement of the ferrule.

When to Replace a Ferrule Fitting

Replace ferrule fittings if they show signs of corrosion, wear, or if they can no longer maintain a leak-proof seal. Regular maintenance can help extend the life of the fittings, but replacement is sometimes necessary to maintain system integrity.

Standards and Certifications

Industry Standards

Ferrule fittings must adhere to industry standards such as ASTM, ISO, and ASME to ensure they meet the necessary safety and performance requirements.

Importance of Compliance

Compliance with these standards is critical for ensuring that ferrule fittings perform reliably in their intended applications, particularly in industries where safety and precision are paramount.

Cost Considerations

Factors Affecting the Cost

Factors such as material, size, and design complexity influence the cost. Stainless steel fittings, for example, tend to be more expensive than brass or plastic fittings due to their superior performance characteristics.

Cost-Benefit Analysis

While ferrule fittings may have a higher initial cost, their durability and reliability often lead to lower overall costs over the life of the system. Performing a cost-benefit analysis can help determine the most cost-effective solution for a specific application.

Buying Guide

Factors to Consider When Purchasing

When purchasing it, consider the following factors: material compatibility with the system’s fluids or gases, pressure and temperature ratings, the size and type of tubing, and the reputation of the manufacturer.

Trusted Manufacturers and Suppliers

Choosing products from reputable suppliers ensures reliability and performance. Some of the leading manufacturers include Swagelok, Parker Hannifin, and Hy-Lok. Taske Ferrule Fitting Manufacturer in China is also a reliable option, offering quality fittings at competitive prices.

Warranty and After-Sales Support

It’s important to consider the warranty and after-sales support when purchasing ferrule fittings. Responsive customer service and a good warranty can provide peace of mind and ensure prompt resolution of any issues with the fittings.

FAQs

What is a Ferrule Fitting?

A ferrule fitting is a widely-used compression fitting that employs a metal ferrule to establish a leak-proof seal between tubing and the fitting body. This fitting is essential for maintaining system integrity, especially in high-pressure environments.

Where are Ferrule Fittings Commonly Used?

Ferrule fittings are commonly used in industries such as oil and gas, chemical processing, pharmaceuticals, and water treatment, as well as in domestic plumbing and HVAC systems.

What Components Make Up a Ferrule Fitting?

Ferrule fittings typically consist of three main components: a nut, a ferrule, and a fitting body. The ferrule is compressed around the tubing by the nut, creating a tight seal.

How Does a Ferrule Fitting Work?

Ferrule fittings work by compressing the ferrule around the tubing as the nut is tightened, forming a leak-proof seal that prevents fluid or gas from escaping.

How Do You Install a Ferrule on Tubing?

To install a ferrule on tubing, you cut and deburr the tubing, slide the nut and ferrule onto the tubing, insert the tubing into the fitting body, and then tighten the nut according to the manufacturer’s instructions.