A hose ferrule is a crucial component in various industrial, automotive, and household applications. It ensures secure connections, enhances durability, and prevents leakage in hose assemblies. Ferrules are widely used across different industries, from simple gardening tools to high-pressure hydraulic systems, playing an essential role in fluid and air transfer applications. In this guide, we’ll explore what a hose ferrule is, its types, applications, and how to choose the right one for your needs.

What Is a Hose Ferrule?

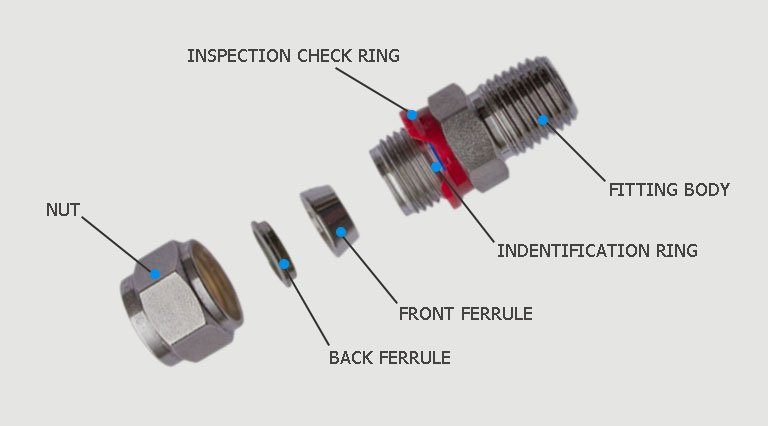

A hose ferrule is a metal or plastic ring crimped onto the end of a hose to reinforce the connection between the hose and its fitting. It helps prevent fraying, leaking, and detachment, ensuring a tight and reliable seal. Ferrules are essential in maintaining the structural integrity of hoses, particularly in environments where extreme temperatures, high pressure, or chemical exposure can weaken hose connections. By using a properly fitted ferrule, the lifespan of the hose is extended, reducing maintenance costs and improving overall system efficiency.

How Does a Hose Ferrule Work?

A hose ferrule works by compressing the hose material around a fitting, creating a mechanical bond that enhances strength and longevity. The crimping process secures the hose in place, preventing it from slipping off under pressure or vibration. This mechanism ensures the hose remains connected even when subjected to extreme forces. In industrial applications, where pressure variations are common, ferrules play an essential role in preventing catastrophic failures. Therefore, crimping or swaging the ferrule tightly ensures an airtight seal. As a result, this process significantly reduces the risks of leaks, which could otherwise lead to system inefficiencies or hazards.

Types of Hose Ferrules

1. Metal Ferrules

- Typically made from aluminum, brass, or stainless steel

- Used in high-pressure applications

- Durable and corrosion-resistant

- Commonly used in hydraulic and pneumatic systems

- Ideal for use in harsh environments where exposure to chemicals or moisture is a concern

2. Plastic Ferrules

- Lightweight and cost-effective

- Used in low-pressure or decorative applications

- Available in various colors for easy identification

- Often used in household applications, such as garden hoses or low-pressure fluid transfer systems

- Can be customized to meet specific aesthetic or functional requirements

3. Crimped Ferrules

- Installed using a crimping tool

- Ensures a tight, leak-proof connection

- Common in hydraulic and pneumatic systems

- Provides a semi-permanent attachment that minimizes the risk of accidental hose detachment

- Helps in achieving consistency in production settings, ensuring uniform hose assemblies

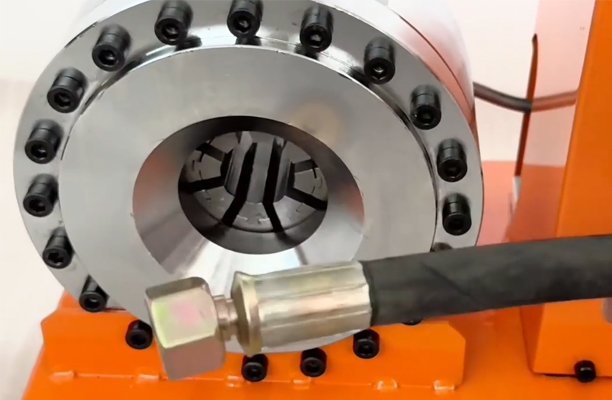

4. Swaged Ferrules

- Applied using a swaging machine

- Offers a more permanent connection than crimped ferrules

- Ideal for industrial applications

- Can handle extreme pressures and temperatures without compromising integrity

- Requires specialized equipment and skilled technicians for proper installation

Common Applications of Hose Ferrules

1. Hydraulic Systems

- Ensures secure connections in high-pressure environments

- Prevents leaks in fluid transfer systems

- Enhances operational safety by reducing hose failure risks

- Used in construction, mining, and heavy machinery industries

- Improves the longevity of hydraulic hoses subjected to constant movement and pressure changes

2. Pneumatic Systems

- Used in air hoses to maintain consistent airflow

- Reduces wear and tear on hose ends

- Essential in manufacturing, automotive, and automation industries

- Helps in reducing air loss, which can impact machine efficiency

- Ensures a tight seal that prevents contaminants from entering the system

3. Automotive Industry

- Essential in fuel and brake line hoses

- Enhances durability in harsh conditions

- Used in air conditioning, cooling, and exhaust systems

- Helps maintain safety and performance standards in vehicles

- Aids in preventing fluid leakage that can lead to engine damage or failure

4. Garden and Water Hoses

- Prevents hose ends from fraying

- Improves water flow efficiency

- Helps in reducing water wastage caused by leaks

- Provides a more secure grip for hose attachments

- Extends the lifespan of the hose by protecting it from excessive bending or kinking

5. Industrial and Manufacturing Uses

- Applied in chemical and gas transfer hoses

- Ensures workplace safety by preventing leaks

- Used in food and beverage industries for sanitary hose applications

- Helps in maintaining pressure consistency in complex industrial systems

- Reduces downtime by ensuring reliable hose performance under demanding conditions

How to Choose the Right Hose Ferrule

Selecting the correct hose ferrule depends on several factors:

1. Material Compatibility

- Match the ferrule material with the hose and fitting for durability

- Stainless steel for corrosive environments, brass for fuel lines

- Consider the type of fluid or gas being transferred to ensure compatibility

- Ensure the ferrule material does not degrade over time due to exposure

2. Hose Size and Pressure Rating

- Ensure the ferrule fits snugly around the hose

- Consider pressure ratings for high-pressure applications

- Measure both the inner and outer diameters of the hose for a precise fit

- Higher pressure applications may require reinforced ferrules for additional strength

3. Type of Connection

- Choose crimped or swaged ferrules based on application needs

- Consider reusability if future adjustments are needed

- Evaluate whether the connection needs to be temporary or permanent

- Ensure proper installation techniques to avoid improper sealing or leaks

How to Install a Hose Ferrule

1: Cut the hose to the desired length using a hose cutter to ensure a clean edge.

2: Slide the ferrule onto the hose before inserting the fitting to avoid misalignment.

3: Position the fitting inside the hose, ensuring a tight fit to prevent leaks.

4: Use a crimping or swaging tool to secure the ferrule in place by applying even pressure.

5: Inspect the connection for any gaps, misalignment, or signs of improper crimping.

Maintenance and Troubleshooting

- Regular Inspections: Check for cracks, corrosion, or loosening to avoid sudden failures.

- Cleaning: Keep ferrules free from dirt and debris to ensure longevity and performance.

- Replacement: If a ferrule shows signs of wear, replace it promptly to avoid failures and costly repairs.

- Proper Storage: Store hoses and ferrules in a clean, dry environment to prevent premature degradation.

Conclusion

A hose ferrule is a small yet essential component that enhances the functionality and longevity of hose assemblies. By understanding the types, applications, and installation process, you can choose the right ferrule for your specific needs. Whether in industrial, automotive, or home applications, using the right ferrule ensures a secure and leak-proof connection, minimizing maintenance issues and improving efficiency.

FAQs

- What is the purpose of a hose ferrule?

- A hose ferrule reinforces hose connections, preventing leaks and ensuring a secure fit.

- Are hose ferrules reusable?

- Most hose ferrules are not reusable, especially crimped or swaged types, as they are permanently attached.

- Can I install a hose ferrule without a crimping tool?

- While some ferrules can be installed manually, a crimping tool is recommended for a secure and reliable connection.

- What materials are hose ferrules made from?

- Hose ferrules are commonly made from aluminum, brass, stainless steel, or plastic, depending on the application.

- How do I choose the right ferrule size?

- Measure the inner and outer diameter of your hose to ensure a proper fit before selecting a ferrule.

- Do hose ferrules affect hose performance?

- Yes, a properly installed ferrule improves durability, prevents leaks, and enhances the overall performance of the hose system.