Introduction

Choosing the right hydraulic fittings supplier is a critical decision that can significantly affect the performance, safety, and reliability of your hydraulic systems. Whether you’re in manufacturing, construction, or agriculture, the durability and efficiency of hydraulic fittings are essential to maintaining uninterrupted operations.

Poor supplier choices can lead to equipment failure, production downtime, and even safety hazards. Therefore, understanding what to look for in a supplier is not just about cost-effectiveness—it’s about long-term system integrity and operational excellence. This guide walks you through the key criteria to consider to ensure you select the best hydraulic fittings supplier for your needs.

Understand Your Hydraulic System Requirements

Before approaching any supplier, you must have a clear understanding of your hydraulic system’s specifications. This foundational step ensures you only evaluate suppliers who can meet your technical needs.

Types of Hydraulic Fittings Needed

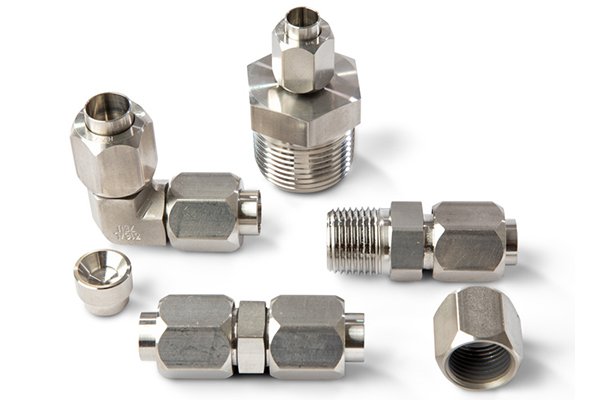

Hydraulic fittings come in various types such as compression fittings, flare fittings, and O-ring face seal fittings. Determine which type is compatible with your current systems to ensure leak-free performance and easy maintenance.

Pressure Ratings and Compatibility

Hydraulic systems operate under varying pressures, and fittings must be rated to withstand those pressures without failure. Always check the PSI (pounds per square inch) rating and ensure it matches or exceeds your system’s requirements. Also, verify the compatibility of materials—brass, stainless steel, and carbon steel are common, but each has its specific application strengths.

Research Potential Suppliers Thoroughly

Once your system requirements are defined, the next step is to create a shortlist of potential suppliers. This involves more than a quick Google search—it requires in-depth research.

Online Reviews and Ratings

Platforms like Trustpilot, Google Reviews, and industry-specific forums offer real-world feedback from customers. Look for recurring themes in reviews such as delayed shipments, poor customer service, or product inconsistencies.

Industry Forums and Recommendations

Engage in conversations on forums like Hydraulic & Pneumatic Network or Reddit’s r/Engineering. These platforms often feature recommendations from professionals who have hands-on experience with various suppliers.

Evaluate Product Quality and Certification

High-quality hydraulic fittings are essential for system safety, longevity, and performance. Suppliers should offer products that meet rigorous industry standards and provide documentation to support their claims.

ISO Certifications and Quality Assurance

Look for suppliers that are ISO 9001 certified, which indicates adherence to internationally recognized quality management standards. This certification signals that the supplier maintains consistent product quality and operational efficiency.

Material Standards and Manufacturing Practices

Investigate whether the fittings are manufactured according to ANSI, SAE, or DIN standards. High-quality suppliers are transparent about their raw material sourcing, heat treatment processes, and machining precision. Don’t hesitate to ask for a mill test report (MTR) to verify metal composition and strength.

Check Inventory and Product Range

A good supplier should offer a wide variety of hydraulic fittings to match different applications, pressures, and fluid types. A diverse product catalog is a sign of a well-established supplier that understands market needs.

Availability of Various Fitting Sizes and Types

Ensure the supplier stocks different types of fittings—JIC, NPT, BSP, ORFS, and more—in a range of thread sizes and materials. This reduces the hassle of sourcing from multiple vendors and speeds up your procurement process.

Custom Fittings Capability

Some applications require non-standard or custom-designed fittings. Choose a supplier with in-house engineering teams or CNC capabilities who can create prototypes and deliver custom parts tailored to your specifications.

Assess Technical Support and Customer Service

Reliable technical support is just as important as the product itself, especially when dealing with complex or large-scale hydraulic systems. A supplier should be your partner, not just a vendor.

Responsiveness and Expertise

Evaluate how quickly and knowledgeably the support team responds to inquiries. Whether it’s helping you select the correct fitting or troubleshooting a leak issue, quick access to expert advice can save time and money.

Support During Emergencies

Ask if the supplier provides 24/7 emergency support or same-day shipping for urgent orders. Their ability to support your operations during breakdowns or urgent upgrades is a vital differentiator.

Consider Pricing and Transparency

While pricing is a crucial factor, it shouldn’t be the sole determinant in your supplier decision. The goal is to find a balance between cost-effectiveness and product reliability. Transparency in pricing builds trust and helps you avoid budget surprises.

Competitive Pricing

Request quotes from multiple suppliers and compare their unit prices, shipping costs, and bulk discounts. Be cautious of prices that are significantly lower than the industry average, as they may indicate inferior materials or manufacturing shortcuts.

Hidden Costs and Clear Quotations

Ensure that the quotation includes all possible charges such as taxes, freight, and surcharges. A reputable supplier will provide a detailed, itemized quote and will not hide fees in fine print or vague language.

Verify Supplier Reliability and Lead Times

Consistent product availability and prompt delivery are essential for maintaining a smooth supply chain. A reliable supplier minimizes the risk of project delays and equipment downtime.

Delivery Timelines and Consistency

Ask for documented lead times and on-time delivery rates. Suppliers who meet their deadlines consistently indicate strong operational control and logistics planning. Delays in receiving fittings can cause costly disruptions to your operations.

Penalties for Late Shipments

In some cases, suppliers may agree to include penalties or discounts for late deliveries in the purchase agreement. This not only protects your timelines but also shows the supplier’s commitment to service level agreements (SLAs).

Review Warranties and Return Policies

Warranties and return policies are crucial indicators of a supplier’s confidence in their products and commitment to customer satisfaction. These policies protect your investment and provide peace of mind.

Product Guarantees

Look for warranties that cover manufacturing defects, material failures, and performance issues. A typical warranty period ranges from 6 months to 2 years, depending on the product type and application.

Hassle-Free Return Procedures

Check whether the supplier offers a straightforward return process in case of incorrect orders or defective products. The best suppliers provide return labels, restocking fee transparency, and a streamlined customer service process for replacements or refunds.

Investigate Supplier’s Industry Experience

Industry experience often correlates with product knowledge, manufacturing consistency, and customer service maturity. A supplier with a solid track record is more likely to anticipate and understand your unique requirements.

Years in Business

Suppliers who have been operating for 10+ years typically possess deeper insights into industry trends, best practices, and product performance. Longevity also suggests financial stability, which can impact their ability to meet ongoing supply demands.

Client Portfolio and Case Studies

Ask for client references or case studies showcasing successful collaborations. These examples provide concrete evidence of the supplier’s ability to deliver quality fittings in different sectors—whether it’s heavy machinery, oil and gas, or automation.

Evaluate Logistics and Geographic Proximity

Logistics play a vital role in lead times, shipping costs, and emergency responsiveness. Where your supplier is located can significantly impact your overall procurement efficiency.

Local vs. International Suppliers

Local suppliers often offer faster shipping, lower freight costs, and easier communication. However, international suppliers may provide lower unit costs or more extensive product ranges. Assess the trade-offs based on your priorities.

Shipping Cost and Time Considerations

Request estimated delivery times and compare standard vs. expedited shipping options. Also, inquire about the supplier’s logistics partners and whether they provide real-time tracking, order confirmation, and customs support for cross-border transactions.

Check for Compliance with Industry Standards

Compliance with national and international standards ensures that the fittings will perform reliably under the intended operating conditions. It also helps meet regulatory and insurance requirements for your equipment and operations.

ANSI, SAE, and DIN Standards Adherence

Ensure that the supplier’s products comply with standards such as ANSI (American National Standards Institute), SAE (Society of Automotive Engineers), or DIN (Deutsches Institut für Normung). These standards define dimensions, tolerances, and testing criteria.

Regulatory Compliance

Depending on your industry and location, check for compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), RoHS (Restriction of Hazardous Substances), and CE markings. Non-compliance can lead to legal and operational complications.

Ask for Samples and Trial Orders

Before committing to large-scale purchases, it’s wise to test a supplier’s products and services through samples or trial orders. This approach allows you to validate the product’s quality and evaluate the company’s overall reliability.

Test Product Performance Before Full Order

Request a few samples or place a small trial order to assess fit, performance, and compatibility with your existing hydraulic system. Evaluate aspects such as thread integrity, pressure handling, and resistance to corrosion.

Evaluate Packaging and Delivery Process

Take note of how the supplier packages their products. Poor packaging can result in damage during transit. Efficient labeling, documentation, and tracking capabilities also reflect the professionalism of the supplier’s logistics system.

Conclusion

Choosing the right hydraulic fittings supplier is a decision that influences your operational efficiency, equipment safety, and maintenance costs. By carefully evaluating suppliers across key factors—product quality, technical support, pricing transparency, industry compliance, and logistics—you can ensure a long-term partnership that adds value to your business.

Don’t rush the process. Invest time in research, seek trial samples, and ask the right questions. A reliable supplier is more than a product provider—they’re an extension of your operations and a contributor to your success.

FAQ

1. What are the most important factors when choosing a hydraulic fittings supplier?

The most critical factors include product quality, certification, technical support, pricing transparency, lead times, and adherence to industry standards. A reliable supplier should also offer comprehensive inventory and responsive customer service.

2. How can I verify the quality of a supplier’s hydraulic fittings?

Check for ISO certifications, material documentation (like mill test reports), and adherence to ANSI, SAE, or DIN standards. Also, request samples or trial orders to test fitting durability, pressure resistance, and compatibility with your system.

3. Why is industry compliance important for hydraulic fittings?

Compliance ensures that the fittings meet safety, performance, and environmental regulations. Non-compliant fittings can cause system failures, legal issues, and costly downtime, especially in regulated industries like aerospace or automotive.

4. Are local suppliers better than international ones?

Local suppliers often provide faster shipping, lower transportation costs, and easier communication. However, international suppliers may offer more competitive pricing or specialized product lines. The best choice depends on your specific logistical and quality needs.

5. Can I order custom hydraulic fittings from most suppliers?

Not all suppliers offer custom manufacturing. Look for suppliers with in-house engineering teams and CNC machining capabilities if you require fittings with non-standard dimensions, materials, or pressure ratings.