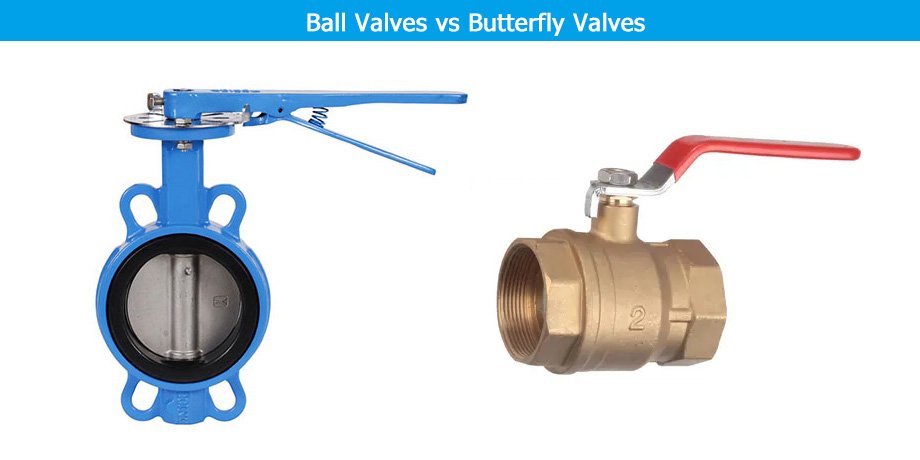

Valves play a critical role in controlling the flow of liquids, gases, or other materials in various systems. From industrial processes to residential plumbing, the choice of the right valve can significantly impact efficiency, safety, and cost-effectiveness. Two of the most commonly used valve types are ball valves and butterfly valves. While both serve the purpose of controlling flow, their design, functionality, and suitability for specific applications vary significantly. This article provides a detailed comparison to help you decide which valve type is the best fit for your needs.

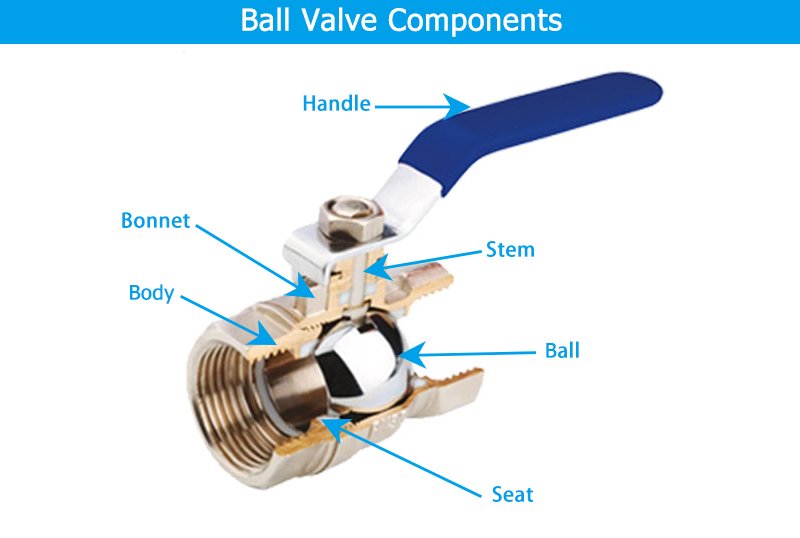

What Are Ball Valves?

Ball valves are a type of quarter-turn valve that uses a spherical ball with a hollow center to control the flow of a fluid or gas. When the hole in the ball is aligned with the flow path, the valve is open; when rotated 90 degrees, the flow is blocked. This simple mechanism makes ball valves reliable and widely used in various applications.

Key Features

- High Sealing Capability: Ball valves provide excellent sealing, reducing the risk of leaks even in high-pressure applications.

- Durability: These valves are known for their robust design, which can withstand extreme temperatures and pressures.

- Versatility: Ball valves are compatible with a wide range of materials and fluids, making them suitable for diverse industries.

Types of Ball Valves

Ball valves come in various types, each designed for specific applications and operational requirements. Understanding these types can help in selecting the right valve for your system. Below are the most common types of ball valves:

1. Full Port Ball Valves

Full port ball valves feature a larger opening that matches the diameter of the pipe, ensuring minimal pressure drop and unrestricted flow. These are ideal for systems where maintaining flow efficiency is critical, such as in pipelines and processing plants.

2. Standard Port Ball Valves

Standard port ball valves have a slightly smaller opening than the pipe diameter, resulting in a moderate pressure drop. They are a cost-effective choice for applications where flow efficiency is less critical.

3. Reduced Port Ball Valves

Reduced port ball valves, also known as reduced bore valves, have a significantly smaller opening compared to the pipe diameter. These are commonly used in applications that do not require full flow, such as in smaller plumbing systems.

4. V-Port Ball Valves

V-port ball valves have a V-shaped ball or seat, allowing for more precise flow control. These valves are excellent for throttling applications where regulating the flow rate is essential.

5. Multi-Port Ball Valves

Multi-port ball valves typically have three or four ports and are used for diverting or mixing flow in complex systems. These are widely used in industries like chemical processing and HVAC systems.

6. Trunnion Mounted Ball Valves

Trunnion mounted ball valves feature additional support for the ball, making them suitable for high-pressure applications. Their design reduces operational torque, enhancing durability and reliability in critical systems.

7. Floating Ball Valves

In floating ball valves, the ball is not fixed but is held in place by the valve seats. This design provides an effective seal and is widely used in low- to medium-pressure systems.

Advantages of Ball Valves

Ball valves offer several benefits, including:

- Full Bore Design: Allows for minimal pressure drop and smooth flow of materials.

- Excellent Shutoff: Provides a tight seal, ideal for preventing leaks in critical systems.

- Low Maintenance: Their simple design requires minimal upkeep, reducing operational costs.

Disadvantages of Ball Valves

Despite their advantages, ball valves have some drawbacks:

- Higher Cost: Compared to other valve types, ball valves can be more expensive initially.

- Bulkier Design: Their size and weight may pose challenges in systems with limited space.

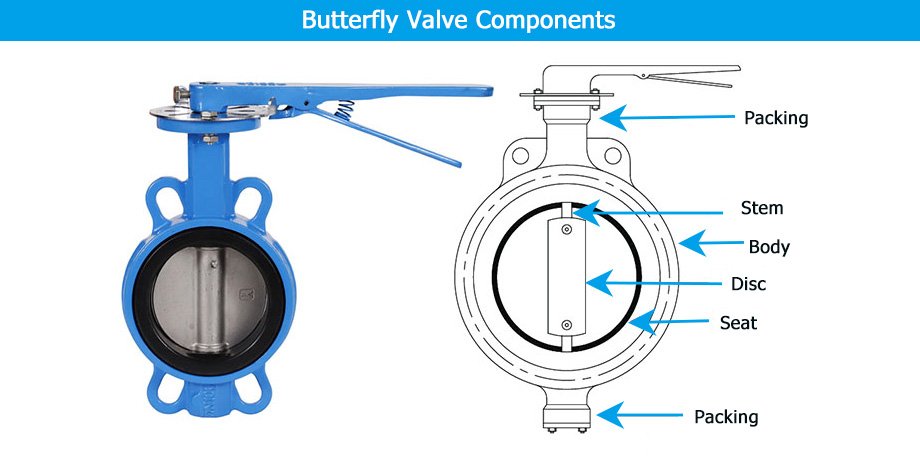

What Are Butterfly Valves?

Butterfly valves are quarter-turn rotational valves that use a disc positioned in the flow path to regulate the flow of a fluid or gas. The valve operates by rotating the disc either parallel or perpendicular to the flow. This design allows for quick opening and closing, making butterfly valves highly efficient in systems requiring frequent flow adjustments.

Key Features

- Lightweight and Compact: Butterfly valves have a streamlined design, making them ideal for space-constrained systems.

- Cost-Effective: Their simple construction and lower material usage reduce manufacturing costs.

- Wide Range of Sizes: Butterfly valves can accommodate both small-scale and large-scale flow requirements.

Types of Butterfly Valves

Butterfly valves come in different types to suit various industrial and residential applications. Each type offers unique features and advantages. Below are the most common types of butterfly valves:

1. Wafer Butterfly Valves

Wafer butterfly valves are designed to fit between two pipe flanges, held in place by bolts that pass through the flanges. They are compact and cost-effective, making them ideal for systems with limited space.

2. Lug Butterfly Valves

Lug butterfly valves feature threaded inserts on both sides, allowing for easy disconnection of one side without affecting the other. This type is commonly used in systems where maintenance or pipeline modifications are frequent.

3. Double Offset Butterfly Valves

Double offset butterfly valves, also known as high-performance butterfly valves, have two offsets from the valve’s centerline. This design reduces friction during operation and improves sealing, making them suitable for high-pressure and high-temperature applications.

4. Triple Offset Butterfly Valves

Triple offset butterfly valves have three offsets: two from the valve centerline and one in the sealing design. These valves provide a metal-to-metal seal, making them ideal for critical applications involving high temperatures, corrosive media, and zero-leakage requirements.

5. Resilient Seated Butterfly Valves

Resilient seated butterfly valves use a flexible rubber seat to create a seal. These are suitable for low-pressure applications, such as water distribution systems and HVAC systems.

6. High-Performance Butterfly Valves

High-performance butterfly valves are engineered to handle moderate to high-pressure systems. They often include advanced materials and designs to improve durability and functionality in demanding environments.

7. Concentric Butterfly Valves

Concentric butterfly valves, also known as zero offset valves, have the disc centered on the valve body. This basic design is often used for general-purpose applications with lower pressure requirements.

Advantages of Butterfly Valves

Butterfly valves provide several benefits, including:

- Ease of Installation: Their compact and lightweight nature simplifies the installation process.

- Throttling Capability: These valves are excellent for controlling flow rates in a system.

- Lower Cost: Butterfly valves are generally more affordable than other valve types, particularly for large pipelines.

Disadvantages of Butterfly Valves

However, butterfly valves also have some limitations:

- Limited Sealing Performance: While suitable for many applications, they may not provide a complete seal in high-pressure or high-temperature systems.

- Flow Turbulence: The presence of the disc in the flow path can cause some turbulence, reducing flow efficiency.

Comparing Ball Valves and Butterfly Valves

Design and Construction

The primary structural difference between ball valves and butterfly valves lies in their flow control mechanism. Ball valves use a spherical ball with a hollow core, while butterfly valves utilize a rotating disc. Ball valves tend to be bulkier due to their construction, whereas butterfly valves are more compact and lightweight, making them suitable for tighter spaces.

Performance in Different Conditions

Ball valves excel in applications requiring high-pressure tolerance and tight sealing. They are ideal for extreme temperatures and corrosive environments. On the other hand, butterfly valves perform well in moderate-pressure systems and are more suitable for large-scale flow control due to their efficient design and cost-effectiveness.

Application-Specific Suitability

For systems that demand precise flow regulation, butterfly valves are often the preferred choice due to their throttling capabilities. However, for applications requiring zero leakage, such as in oil and gas pipelines, ball valves are the superior option.

Maintenance and Longevity

Ball valves are generally easier to maintain due to their simple and durable design, which also contributes to a longer lifespan. Butterfly valves, while requiring more frequent maintenance, offer the advantage of easy disc replacement, reducing downtime in large systems.

Cost Considerations

When comparing costs, butterfly valves are more affordable, particularly for larger diameters. However, ball valves, though pricier, often prove to be more cost-effective in the long term due to their durability and lower maintenance requirements.

Ball Valves vs Butterfly Valves: Use Cases

Industrial Applications

In industrial settings, ball valves are widely used in oil and gas operations, chemical processing, and power generation due to their excellent sealing properties. Butterfly valves, on the other hand, are commonly employed in water treatment plants, HVAC systems, and large-scale pipelines for their cost-efficiency and ease of installation.

Residential Applications

For residential plumbing and heating systems, both ball valves and butterfly valves can be utilized depending on the specific requirements. Ball valves are often preferred for their reliable shutoff capabilities, while butterfly valves are chosen for their compactness in restricted spaces.

Specialized Applications

Ball valves are indispensable in environments dealing with highly corrosive or viscous substances, such as in chemical industries. Butterfly valves are favored in systems where lightweight and large-diameter valves are required, such as in marine or water distribution networks.

Pros and Cons Summary Table

| Aspect | Ball Valves | Butterfly Valves |

|---|---|---|

| Sealing Capability | Excellent | Moderate |

| Size and Weight | Bulky | Compact |

| Cost | Higher | Lower |

| Flow Regulation | Limited | Excellent |

| Maintenance | Low | Moderate |

| Durability | High | Moderate |

How to Choose the Right Valve for Your Needs

Key Factors to Consider

When selecting between ball valves and butterfly valves, it is essential to assess the specific requirements of your system. Key factors to consider include:

- Pressure and Temperature: Determine the maximum pressure and temperature levels your valve needs to withstand. Ball valves are better for high-pressure systems, while butterfly valves work well under moderate conditions.

- Flow Control Needs: If precise flow regulation or throttling is a priority, butterfly valves are often the preferred choice.

- Space Constraints: For compact installations, butterfly valves are more suitable due to their slim profile.

- System Budget: Evaluate both the initial costs and long-term maintenance expenses to make an informed decision.

Consulting Experts

Choosing the right valve for your application can be a complex process, especially for specialized or large-scale systems. Consulting with industry experts or valve suppliers can provide valuable insights into the most suitable options for your needs. They can help assess factors such as material compatibility, pressure ratings, and environmental conditions.

Conclusion

Both ball valves and butterfly valves serve as essential components in various industrial and residential systems. While ball valves are renowned for their exceptional sealing capabilities and durability, butterfly valves stand out for their compact design and cost-effectiveness in large-scale applications. Understanding the specific requirements of your system, such as pressure, temperature, and flow control needs, is crucial for selecting the right valve.

By carefully evaluating these factors and consulting with experts, you can make an informed choice that ensures optimal performance, efficiency, and cost savings in your operations.

FAQs

What is the primary difference between ball valves and butterfly valves?

The main difference lies in their design and operation. Ball valves use a spherical ball to control flow, providing tight shutoff, while butterfly valves use a rotating disc and are better suited for throttling and large-scale applications.

Which valve is better for high-pressure applications?

Ball valves are better for high-pressure applications due to their superior sealing capabilities and robust construction.

Can butterfly valves handle corrosive materials?

Yes, butterfly valves can handle corrosive materials if they are made from the appropriate corrosion-resistant materials. However, their sealing capabilities may not match those of ball valves in such conditions.

Are ball valves more expensive than butterfly valves?

Generally, ball valves are more expensive than butterfly valves, especially in larger sizes. However, their durability and lower maintenance costs can make them more cost-effective in the long term.

Which valve is easier to install in tight spaces?

Butterfly valves are easier to install in tight spaces due to their compact and lightweight design.