When it comes to connecting hoses for plumbing, industrial systems, or even homebrew setups, hose barb fittings are the unsung heroes. These small but mighty components ensure tight, reliable connections that keep systems running smoothly. But what exactly are hose barb fittings? Why are they so widely used, and how can you make sure you’re choosing the right one for your needs?

In this blog, we’ll break down everything you need to know about hose barb fittings, from their design and materials to their applications and installation tips. Stick around to master the basics and elevate your understanding of these essential tools!

What Are Hose Barb Fittings?

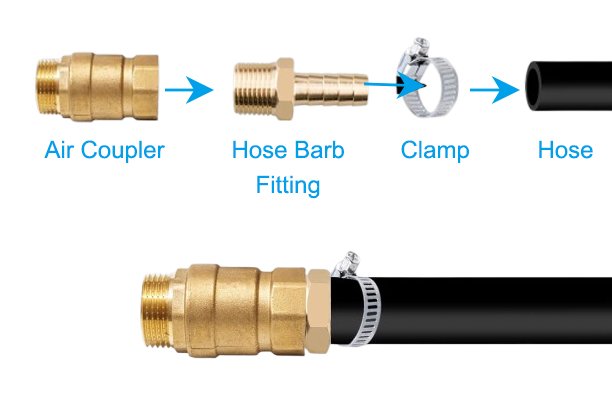

Hose barb fittings are small but critical components designed to create a secure connection between hoses and other system components like pipes, valves, or equipment. Their defining feature is their barbed, ribbed end, which grips the inside of a hose when inserted. When combined with a clamp or crimp ring, these fittings form a tight, leak-proof seal that can withstand pressure and various conditions.

Think of hose barb fittings as the glue that holds flexible hoses in place, ensuring fluids, air, or gases flow smoothly without any leakage. They’re incredibly versatile and are used in a broad range of industries, from plumbing to automotive and even medical systems.

How They Work

The magic of hose barb fittings lies in their barbed design. The ridges on the barb create friction when inserted into the hose, gripping it tightly. The pressure from the hose combined with a clamp secures the connection further, preventing the hose from slipping off or leaking. This simple design eliminates the need for complex tools or welding, making hose barb fittings easy to install and reliable over time.

Common Applications of Hose Barb Fittings

You’ll find hose barb fittings in a wide range of industries and applications, including:

- Plumbing: For connecting pipes and hoses in water systems.

- Automotive: Used in fuel lines, cooling systems, and vacuum hoses.

- Home Brewing: Essential for transferring liquids in brewing setups.

- Agriculture: Widely used in irrigation systems and sprayers.

- HVAC Systems: Ideal for securing refrigerant and coolant hoses.

Why Use Hose Barb Fittings?

You might be wondering, why are hose barb fittings the go-to solution for so many professionals and DIY enthusiasts? Well, it’s all about their combination of simplicity, affordability, and reliability. Let’s break down the key reasons:

1. Leak Prevention

Thanks to their barbed design, these fittings create a secure seal that significantly reduces the chance of leaks. The ridges provide extra grip, and when paired with a clamp, the seal becomes even tighter, ensuring no fluids escape.

2. Ease of Installation

Unlike other connectors that may require complex tools, welding, or adhesives, hose barb fittings are incredibly straightforward to use. Simply slide the hose over the barb, secure it with a clamp, and you’re good to go! This simplicity saves time and effort, making them a popular choice for professionals and DIYers alike.

3. Cost-Effective

When compared to other types of fittings, hose barb fittings are often more affordable while still offering excellent performance. Their durability ensures you don’t have to replace them frequently, further adding to their cost-effectiveness.

4. Versatility

Hose barb fittings are compatible with a wide range of hose types, including rubber, vinyl, and polyurethane hoses. They’re also suitable for various applications, from low-pressure systems to high-pressure industrial setups, as long as the material is chosen appropriately.

5. Durability

These fittings are designed to handle tough conditions, including high temperatures, chemical exposure, and physical wear. Materials like stainless steel or brass can even withstand corrosive environments, making them a reliable choice for critical systems.

6. Compact Design

With their small and lightweight structure, hose barb fittings don’t add unnecessary bulk to a system. They’re ideal for applications where space is tight or weight is a concern, like in automotive or aerospace systems.

Types of Hose Barb Fittings

One of the best things about hose barb fittings is their variety. Depending on your needs, you can choose from several types, each designed for specific applications. Here’s a closer look at the main types:

1. Straight Hose Barb Fittings

- What Are They?

Straight barb fittings are the most basic and commonly used type. As the name suggests, they connect hoses in a straight line, allowing fluid to flow uninterrupted from one point to another. - Where Are They Used?

They’re ideal for applications where there’s no need to bend or alter the direction of the flow. Think of water lines in a plumbing system or simple fluid transfer setups in an industrial process.

2. Elbow Hose Barb Fittings

- What Are They?

Elbow fittings are designed to create a 90-degree angle between two hoses. This is particularly useful for setups where space is limited or where hoses need to bend without kinking or obstructing flow. - Where Are They Used?

Elbow barb fittings are often used in automotive cooling systems, irrigation setups, or anywhere a change in direction is required in tight spaces. - Advantages:

- Prevents hose kinks.

- Saves space in compact systems.

- Maintains smooth fluid flow despite directional changes.

3. Tee Hose Barb Fittings

- What Are They?

Tee fittings are shaped like the letter “T” and are used to split or combine the flow of fluid between three hoses. - Where Are They Used?

These fittings are common in irrigation systems, brewing setups, and any system that requires branching or combining fluid flow. - Advantages:

- Distributes fluid to multiple outlets.

- Ideal for multi-line systems.

4. Reducing Hose Barb Fittings

- What Are They?

Reducing barb fittings are used to connect hoses of different sizes. One end of the fitting has a smaller barb, while the other has a larger one, allowing for seamless transitions. - Where Are They Used?

These are great for systems where fluid flow needs to change between hoses of varying diameters, such as in fuel lines or custom plumbing projects. - Advantages:

- Easy transitions between hose sizes.

- Maintains a strong, leak-free connection.

5. Dual-Barbed Hose Fittings

- What Are They?

Dual-barbed fittings have barbs on both ends, designed to join two hoses directly without any additional connectors. - Where Are They Used?

Perfect for extending hoses or repairing damaged sections. - Advantages:

- Simple solution for hose extensions.

- No complex installation required.

6. Specialty Hose Barb Fittings

In addition to the standard types, there are specialty fittings designed for unique applications, such as quick-connect fittings or swivel barb fittings. These are tailored to meet specific system requirements, like easy disconnection or 360-degree movement.

Why Understanding Types Matters

Selecting the right type of hose barb fitting is crucial for ensuring your system runs smoothly. Using the wrong fitting can lead to leaks, reduced efficiency, or even system failure. By understanding the different types and their applications, you can make informed decisions and build a reliable setup.

How to Choose the Right Hose Barb Fitting

Selecting the right hose barb fitting is crucial for ensuring a leak-free, durable, and efficient system. Whether you’re working on a plumbing project, an industrial process, or a DIY setup, making the correct choice can save you time, money, and headaches down the road. With so many options available in terms of material, size, and design, the decision can feel overwhelming. But don’t sweat it!

1. Determine the Hose Size

The first step in choosing the right hose barb fitting is ensuring it matches the size of your hose. Hose barb fittings are sized based on the internal diameter (ID) of the hose they will connect to.

- Why is this important?

If the barb is too small, the hose won’t seal properly, leading to leaks. If it’s too large, you’ll struggle to slide the hose onto the barb, and it may damage the hose. - How to measure hose size:

- Measure the internal diameter (ID) of the hose using a caliper or ruler.

- Match the barb size to the hose ID. For example, if your hose has an ID of ½ inch, you’ll need a ½-inch barb fitting.

2. Consider the Material

The material of the hose barb fitting plays a big role in its durability, resistance to corrosion, and ability to handle specific fluids or gases. Here’s a breakdown of common materials and when to use them:

- Brass

- Best for: Plumbing, water systems, and mild chemical applications.

- Advantages: Corrosion-resistant, affordable, and easy to work with.

- Limitations: Not ideal for highly acidic or corrosive environments.

- Stainless Steel

- Best for: High-pressure applications, harsh environments, and corrosive chemicals.

- Advantages: Extremely durable, corrosion-resistant, and can handle high temperatures.

- Limitations: More expensive than brass or plastic options.

- Plastic (PVC or Nylon)

- Best for: Low-pressure applications, such as irrigation or homebrew systems.

- Advantages: Lightweight, affordable, and resistant to many chemicals.

- Limitations: Not suitable for high temperatures or pressure.

- Aluminum

- Best for: Automotive or lightweight industrial applications.

- Advantages: Lightweight, strong, and moderately corrosion-resistant.

- Limitations: Less durable in highly corrosive or high-pressure environments.

- Copper

- Best for: Certain plumbing or aesthetic applications.

- Advantages: Great for thermal conductivity and aesthetics.

- Limitations: Limited use in high-pressure or industrial settings.

3. Assess Pressure Requirements

Different systems operate under varying pressure levels, and your hose barb fitting needs to handle the specific pressure of your application.

- Low-Pressure Systems:

Plastic or brass fittings are typically sufficient for applications like irrigation, home plumbing, or low-pressure fluid transfer. - Medium to High-Pressure Systems:

Opt for stainless steel or brass fittings in applications such as industrial systems, fuel lines, or hydraulic setups. - How to Check Pressure Ratings:

- Look at the manufacturer’s specifications for the fitting’s maximum pressure rating.

- Ensure the fitting can handle the pressure of your system without failure.

4. Think About Temperature Compatibility

Temperature extremes can cause fittings to fail if they’re made from the wrong material. Consider the operating temperature of your system:

- High-Temperature Environments:

Stainless steel or brass fittings are ideal for high-heat systems, such as automotive cooling systems or industrial boilers. - Low-Temperature Environments:

Plastic fittings may work well in systems that don’t generate a lot of heat, such as garden irrigation systems or food-grade applications.

5. Evaluate Chemical Resistance

If you’re working with chemicals, oils, or gases, it’s essential to choose a fitting material that can resist corrosion and degradation.

- Brass: Suitable for water and mild chemicals but may corrode with strong acids or alkalis.

- Stainless Steel: Excellent for harsh chemicals, acids, and even saltwater.

- Plastic: Works well with many non-corrosive chemicals but isn’t suitable for high temperatures or pressures.

Pro Tip:

Always check the compatibility of the fitting material with the fluid or gas running through your system. Manufacturers often provide compatibility charts to make this process easier.

6. Select the Right Fitting Type

The type of hose barb fitting you choose depends on the system layout and the specific function the fitting will perform. Here’s a quick refresher on fitting types:

- Straight Barb Fittings:

Ideal for connecting two hoses in a straight line. Best for simple, uninterrupted fluid transfer. - Elbow Barb Fittings:

Perfect for tight spaces or when a 90-degree turn is needed to avoid hose kinks. - Tee Barb Fittings:

Used for splitting or combining fluid flow into three different directions. Great for irrigation or multi-line systems. - Reducing Barb Fittings:

Needed for connecting hoses of different sizes, especially in systems where the fluid flow changes diameter. - Swivel Barb Fittings:

Allow hoses to rotate or move without causing stress on the fitting. Best for dynamic systems with moving parts.

7. Understand Space Constraints

If you’re working in a compact or crowded system, you’ll need fittings that fit neatly without taking up too much space.

- Compact Fittings: Elbow or tee fittings work better in tight spaces.

- Straight Fittings: Best for systems with plenty of room for linear connections.

8. Account for Aesthetic and Functional Considerations

In some cases, aesthetics and ease of use also matter. For instance:

- Aesthetic Projects: Copper or brass fittings may be chosen for their appearance in exposed systems.

- Quick-Disconnect Systems: Opt for fittings with quick-connect or swivel features to make disassembly and reassembly easier.

9. Clamp Compatibility

No matter how well your fitting matches your hose, it won’t stay secure without a proper clamp. Make sure the fitting you choose is compatible with common clamps, such as:

- Worm gear clamps

- Spring clamps

- Oetiker clamps

10. Verify Certification or Industry Standards

For certain industries (e.g., medical, food-grade, or high-pressure systems), it’s important to ensure your fittings meet regulatory standards or certifications, such as:

- FDA approval for food or drink systems.

- NSF certification for potable water.

- ASME standards for industrial use.

Installation Tips for Leak-Free Connections

Installing hose barb fittings is a breeze, but a few extra steps can ensure a truly leak-free setup:

- Cut the Hose Cleanly: Use a sharp blade to cut the hose straight for a flush connection.

- Heat the Hose (Optional): Warming the hose slightly can make it easier to slide onto the barb.

- Use Hose Clamps: Secure the hose with a high-quality clamp to prevent leaks or slippage.

- Check for Leaks: After installation, run water or air through the system to ensure no leaks are present.

FAQs

1. What are hose barb fittings used for?

Hose barb fittings are used to securely connect flexible hoses to pipes, valves, or equipment in systems like plumbing, automotive, and irrigation.

2. How do hose barb fittings prevent leaks?

The ridges (or barbs) on the fitting grip the inside of the hose tightly, and a hose clamp is added to further secure the connection, preventing leaks.

3. What materials are hose barb fittings made from?

Hose barb fittings are commonly made from brass, stainless steel, plastic (PVC or nylon), or aluminum, depending on the application.

4. Do I need a clamp with hose barb fittings?

Yes! A clamp ensures the hose stays firmly in place and creates a tighter, leak-free seal around the barb.

5. Can hose barb fittings handle high-pressure systems?

Yes, but only if they’re made from durable materials like stainless steel or brass. Plastic fittings are better suited for low-pressure systems.

6. How do I choose the right size hose barb fitting?

Match the internal diameter (ID) of your hose to the size of the barb on the fitting. For example, a ½-inch barb works with a hose that has a ½-inch ID.

Conclusion

Hose barb fittings are the backbone of many plumbing, automotive, and industrial systems. Their simple yet effective design ensures secure, leak-free connections that stand the test of time. Whether you’re working on a small DIY project or managing a large-scale setup, understanding these fittings will help you make better choices and avoid costly mistakes.