Pipe fitting unions are indispensable components in plumbing and industrial piping systems, allowing for the easy connection and disconnection of pipes. They simplify maintenance and repairs and are crucial for maintaining the efficiency and functionality of various systems. This guide delves deeply into pipe fitting unions, examining their types, materials, installation, and applications. We also explore their historical evolution, real-world case studies, and future trends.

What is a Pipe Fitting Union?

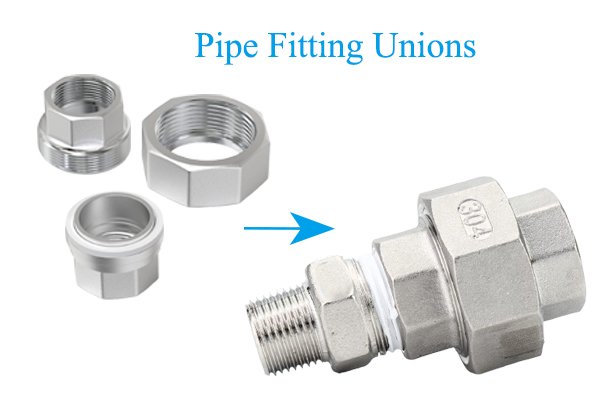

A pipe fitting union is a device that enables the joining of two pipes while allowing for easy separation. Unlike couplings, which create a permanent connection, unions are designed to be easily disassembled for maintenance or repair. They consist of three primary components:

- Male End: This part screws into the female end of the connecting pipe.

- Female End: Receives the male end, forming a secure connection.

- Nut: A central component that tightens and locks the male and female ends together.

A gasket, typically made of rubber or plastic, is included to create a leak-proof seal.

Types of Pipe Fitting Unions

Pipe fitting unions come in various types, each suited for specific applications:

- Threaded Unions:

- Description: Feature male and female threaded ends that screw onto each other.

- Uses: Common in metal pipes such as steel and brass, where threads provide a secure connection.

- Advantages: Easy to install and remove, making them suitable for applications requiring frequent disconnection.

- Flange Unions:

- Description: Utilize flanges and bolts to secure pipes together.

- Uses: Ideal for high-pressure industrial applications where a robust connection is needed.

- Advantages: Provide a strong and durable connection, capable of withstanding high pressures and harsh conditions.

- Compression Unions:

- Description: Feature a compression nut that tightens around the pipe, creating a secure seal.

- Uses: Commonly used in smaller diameter pipes, especially in residential water supply systems.

- Advantages: Simple installation and effective for maintaining a leak-proof seal.

Materials Used for Pipe Fitting Unions

The choice of material for pipe unions affects their performance and durability:

- Brass:

- Benefits: Corrosion-resistant, durable, and suitable for both hot and cold water applications.

- Common Uses: Frequently used in residential plumbing and heating systems due to its versatility and reliability.

- Stainless Steel:

- Benefits: Highly resistant to corrosion and extreme temperatures, making it ideal for harsh environments.

- Common Uses: Preferred for industrial settings where exposure to chemicals or high temperatures is common.

- PVC (Polyvinyl Chloride):

- Benefits: Lightweight, cost-effective, and resistant to corrosion.

- Common Uses: Used in plastic piping systems and non-pressurized applications, such as drainage systems.

- Copper:

- Benefits: Excellent thermal conductivity and good corrosion resistance.

- Common Uses: Common in plumbing systems and heating installations due to its conductivity and resistance to corrosion.

How Pipe Fitting Unions Work

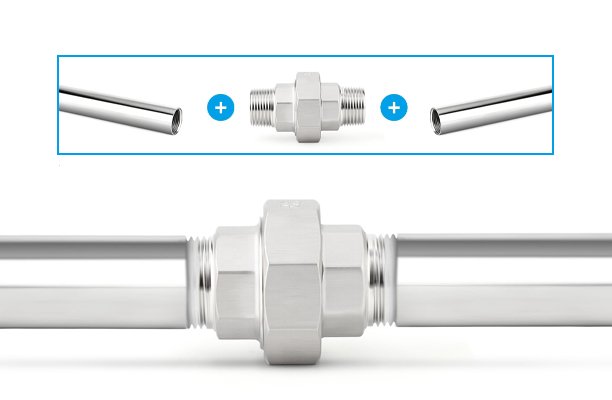

Pipe unions are designed to facilitate easy connection and disconnection:

- Connection: Screw the male and female ends of the union onto the pipes. Use thread seal tape or pipe dope to ensure a leak-proof seal.

- Securing: Tighten the central nut with a wrench to lock the pipes in place and ensure a secure connection.

- Disconnection: To remove the union, unscrew the nut, separating the pipes without the need for cutting.

Advantages

Pipe unions offer several key benefits:

- Ease of Disassembly: Simplifies maintenance and repair tasks by allowing easy separation of pipes.

- Versatility: Compatible with a wide range of pipe materials and sizes, making them adaptable to various systems.

- Leak Prevention: Provides a secure, leak-proof seal when properly installed, reducing the risk of water or gas leaks.

- Cost-Effectiveness: Reduces maintenance and repair costs compared to permanent fittings, as they can be easily replaced or serviced.

Applications

Unions are used in various applications:

- Residential Plumbing: Facilitates connections and disconnections in water supply systems, making repairs and upgrades easier.

- Commercial Piping Systems: Used in HVAC systems, drainage systems, and fire protection systems where ease of maintenance is crucial.

- Industrial Piping: Handles chemicals, gases, and other substances, requiring robust and reliable connections.

Difference Between Pipe Unions and Couplings

While both unions and couplings join pipes, they serve different purposes:

- Couplings: Create permanent connections, often through welding or adhesives. They are less convenient for systems requiring frequent maintenance.

- Unions: Allow for easy disconnection and reconnection, making them ideal for applications that require regular access or adjustments.

Pipe Fitting Union Installation Process

Proper installation is crucial for ensuring a reliable connection:

- Prepare the Pipes: Cut the pipes to the correct length and smooth the edges to ensure a proper fit.

- Attach the Union: Screw the male and female ends of the union onto the pipes, using thread seal tape or pipe dope to prevent leaks.

- Tighten the Union: Use a wrench to tighten the central nut, ensuring a secure connection without over-tightening.

- Test for Leaks: Run water or air through the pipes to check for leaks. Tighten the connection if necessary to eliminate any leaks.

Tools Needed for Installing Pipe Fitting Unions

Essential tools include:

- Pipe Cutter or Hacksaw: For cutting pipes to the correct length.

- Wrench: Adjustable or pipe wrench for tightening the union.

- Thread Seal Tape or Pipe Dope: For creating a leak-proof seal.

- Deburring Tool: For smoothing pipe edges to prevent damage to the union.

Common Challenges During Installation

Be aware of these challenges:

- Misalignment: Ensure proper alignment of the union to prevent leakage and ensure a secure connection.

- Overtightening: Avoid damaging the threads or gasket by tightening the union just enough to create a secure seal.

- Improper Sealing: Use the correct sealant to prevent leaks and ensure a reliable connection.

Pipe Fitting Unions in Plumbing Systems

In plumbing systems, pipe unions are crucial for:

- Connecting Dissimilar Materials: Allow flexible system design by connecting pipes made from different materials.

- Handling Thermal Expansion: Provide adjustable connections that accommodate the expansion or contraction of pipes due to temperature changes.

How to Maintain Pipe Fitting Unions

Proper maintenance extends the lifespan of pipe unions:

- Regular Inspections: Check for signs of wear, corrosion, or leaks.

- Tightening: Gently tighten the union if leaks are detected, but avoid over-tightening.

- Cleaning: Remove dirt and debris from the union to prevent interference with its operation.

- Gasket Replacement: Replace degraded gaskets to maintain a leak-proof seal.

- Reapply Thread Sealant: Reapply sealant after disassembling and reassembling the union.

Durability and Longevity

The durability of pipe unions depends on:

- Material: Brass, stainless steel, and PVC offer varying levels of durability.

- Environment: Exposure to temperature extremes, pressure, and corrosive elements impacts the lifespan of the union.

Factors to Consider When Choosing Pipe Fitting Unions

Consider these factors when selecting a pipe union:

- Material Compatibility: Match the union material with the pipe material and the type of fluid or gas being transported.

- Pressure Rating: Ensure the union is rated for the system’s pressure to prevent failures.

- Temperature Resistance: Choose unions that can withstand the operating temperature of the system.

- Size: Select the appropriate size for a secure and effective connection.

- Seal Type: Ensure the gasket material is suitable for the application to prevent leaks.

How to Identify a Faulty Pipe Union

Signs of a faulty union include:

- Visible Leaks: Check for escaping water or gas around the union.

- Corrosion or Rust: Inspect for rust or corrosion on metal unions.

- Loosened Connection: Tighten the union if it feels loose.

- Cracks or Damage: Replace the union if you observe any physical damage.

Safety Considerations

Ensure safety by:

- Using Appropriate PPE: Wear gloves, goggles, and boots during installation and maintenance.

- Following Pressure Guidelines: Adhere to the pressure rating of the union to prevent failures.

- Inspecting Regularly: Perform regular inspections to identify potential issues before they become major problems.

Conclusion

Pipe fitting unions are essential for a wide range of piping systems, offering flexibility, ease of maintenance, and reliable performance. By understanding their types, materials, installation processes, and applications, you can make informed decisions for your projects. Keeping up with innovations and adhering to best practices ensures the longevity and efficiency of your piping systems.

FAQ

What is the purpose of a pipe fitting union?

A pipe fitting union connects two pipes while allowing for easy disconnection and reconnection, making maintenance and repairs simple.

How do I know if my pipe union is leaking?

Signs of a leaking pipe union include visible water or gas escaping from the joint, corrosion around the union, or a loosened connection.

Can pipe unions be used with gas lines?

Yes, pipe unions can be used in gas lines, but it’s essential to select unions specifically rated for gas use and ensure they are installed according to safety standards.

Are unions better than couplings?

Unions are preferred when frequent disassembly or maintenance is required, while couplings are better for permanent, long-term connections.

How long do pipe unions last?

The lifespan of a pipe union depends on the material and environment, but high-quality unions made from materials like stainless steel or brass can last decades.

Do I need a professional to install a pipe fitting union?

While installing a pipe fitting union is relatively simple, hiring a professional ensures proper installation and reduces the risk of leaks or damage.