PEX, or cross-linked polyethylene, is a versatile thermoplastic widely used due to its variable crystalline structure. Among the most produced plastics globally, polyethylene comes in several densities including low-density (LDPE) and high-density (HDPE). LDPE is commonly used for products like trash bags and frozen food packaging, whereas HDPE’s stiffer structure makes it ideal for applications such as PEX fittings and tubing.

PEX fittings, which connect tubing sections or link PEX to other materials like copper or manifolds, often feature barbed ends for better grip. These fittings can be crafted from various materials including brass, poly alloy (plastic), bronze, and even stainless steel for highly corrosive environments. They come in several types such as crimp, push-to-connect, compression, expansion, and press-fit.

Understanding PEX Fittings

What Are PEX Fittings?

PEX fittings are connectors that join PEX pipes to create a reliable water distribution system. These fittings play an integral role in maintaining the integrity of plumbing systems by ensuring watertight connections. Available in various forms like elbows, tees, couplings, and valves, PEX fittings cater to different plumbing layouts and flow requirements.

PEX fittings are crucial because they:

- Create durable connections without compromising pipe flexibility.

- Simplify the process of building plumbing systems.

- Allow for the customization of complex layouts, including loops and branch systems.

Types of PEX Fittings

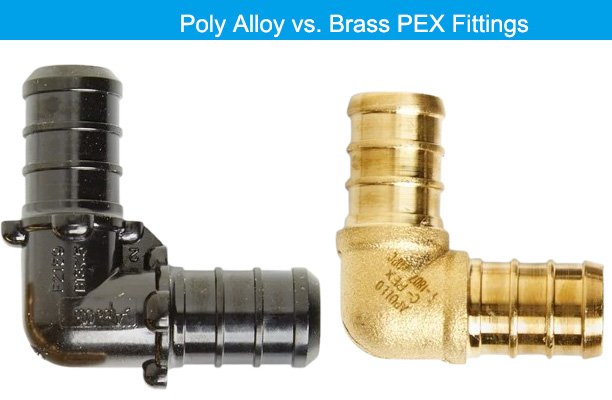

PEX fittings can be made from different materials, with poly alloy and brass being the most commonly used options. Each material offers distinct advantages and trade-offs. While poly alloy fittings are composed of durable plastic polymers, brass fittings use a copper-zinc alloy, offering different performance characteristics for varying applications.

Other less common types of fittings include:

- Stainless steel clamps

- Copper crimp rings

- Push-to-connect systems

Importance of Choosing the Right Fitting

Choosing the appropriate fitting is critical to the overall efficiency and lifespan of your PEX plumbing system. The wrong material can lead to:

- Premature failure due to corrosion or wear.

- Performance issues under specific temperature and pressure conditions.

- Increased maintenance costs and frequent repairs.

Factors like water quality, environmental exposure, and budget should guide your decision.

Poly Alloy PEX Fittings

What Are Poly Alloy PEX Fittings?

Poly alloy PEX fittings, also known as plastic fittings, are manufactured from polyphenylsulfone (PPSU). This material is a high-performance polymer known for its strength, chemical resistance, and lightweight properties. These fittings comply with standards like ASTM F2159, ensuring their reliability in potable water systems.

Poly alloy fittings are produced using an injection molding process, which creates precisely shaped fittings. This method ensures consistent performance and allows the production of various shapes, including elbows, tees, and couplings.

Benefits of Poly Alloy PEX Fittings

Poly alloy PEX fittings have several advantages that make them a preferred choice for certain applications:

- Corrosion Resistance

These fittings are impervious to corrosion, even in environments with highly acidic or alkaline water. This makes them ideal for areas with poor water quality. - Lightweight Design

Being made of plastic, poly alloy fittings are lightweight, which reduces shipping costs and simplifies installation. - Cost-Effectiveness

Poly alloy fittings are generally less expensive than brass fittings, providing a more economical solution for residential plumbing systems. - Non-Toxic and Safe for Potable Water

Certified for potable water use, these fittings are safe for residential and commercial plumbing systems. - Quiet Operation

Poly alloy fittings contribute to quieter plumbing systems by reducing vibrations and water hammer noise.

Limitations of Poly Alloy PEX Fittings

Despite their benefits, poly alloy PEX fittings have certain limitations:

- Durability Concerns

Poly alloy fittings are less robust than brass fittings and may not perform well under high mechanical stress or heavy loads. - Temperature Sensitivity

These fittings may warp or degrade under extreme heat, limiting their suitability for high-temperature applications like hydronic heating systems. - Limited Lifespan

While durable, their lifespan is typically shorter than that of brass fittings, especially in demanding environments. - UV Degradation

Prolonged exposure to sunlight can weaken poly alloy fittings, making them unsuitable for outdoor applications unless adequately protected.

Brass PEX Fittings

What Are Brass PEX Fittings?

Brass PEX fittings are made from a combination of copper and zinc, creating a strong and durable material. These fittings are versatile and can handle a wide range of applications, from hot water systems to outdoor plumbing. Brass fittings are often manufactured using precision machining, which ensures tight tolerances and a perfect fit with PEX tubing.

Brass fittings conform to ASTM F1807 standards, which regulate dimensional accuracy, pressure ratings, and corrosion resistance. They are also available in various designs, such as barb fittings and threaded connections, making them adaptable to different systems.

Advantages of Brass PEX Fittings

Brass fittings offer a range of benefits, including:

- Exceptional Durability

Brass fittings can withstand high pressures and mechanical stress, making them suitable for demanding applications. - High-Temperature Resistance

Unlike poly alloy fittings, brass maintains its integrity in hot water systems, including hydronic heating. - Long Lifespan

With proper installation and maintenance, brass fittings can last for decades without significant degradation. - Corrosion Resistance in Controlled Conditions

Modern brass alloys are resistant to dezincification, a type of corrosion caused by high chlorine or acidic water. - Recyclability

Brass is 100% recyclable, making it a sustainable option for eco-conscious projects.

Drawbacks of Brass PEX Fittings

Despite their advantages, brass fittings have some downsides:

- Vulnerability to Corrosion

In systems with high chloride or sulfide levels, brass fittings may corrode over time, potentially leading to leaks. - Higher Cost

Brass fittings are more expensive than poly alloy, which can increase the overall cost of a project. - Weight

Being heavier than poly alloy, brass fittings may be less practical for large-scale installations.

Side-by-Side Comparison: Poly Alloy vs. Brass PEX Fittings

| Feature | Poly Alloy PEX Fittings | Brass PEX Fittings |

|---|---|---|

| Material Composition | High-performance plastic (PPSU) | Copper-zinc alloy |

| Durability | Moderate | High |

| Corrosion Resistance | Excellent | Moderate (varies with water quality) |

| Temperature Tolerance | Low to moderate | High |

| Weight | Lightweight | Heavier |

| Cost | More affordable | More expensive |

| Lifespan | 10–15 years | 20–50 years |

Key Applications and Use Cases

Residential Plumbing

In residential plumbing, both poly alloy and brass PEX fittings are widely used, but their selection depends on the specific needs of the system. Here’s how each performs in this context:

- Poly Alloy Fittings for Residential Use

Poly alloy fittings are ideal for indoor plumbing systems where water quality is poor or where there is minimal risk of extreme temperatures. Their lightweight design and lower cost make them an excellent choice for homeowners seeking an economical solution without sacrificing performance. - Brass Fittings for Residential Use

Brass fittings are preferred for areas with high-temperature water systems, such as hot water heaters and radiant heating systems. Their durability ensures longevity, reducing the need for frequent repairs or replacements.

Scenario Example: A residential home with hard water (high mineral content) would benefit from poly alloy fittings to avoid corrosion. Conversely, a home with a hydronic heating system would favor brass for its heat resistance.

Commercial Plumbing

Commercial plumbing systems are more demanding due to their scale and constant usage. Here’s how the two types of fittings compare:

- Poly Alloy in Commercial Settings

Poly alloy fittings can be used in low-demand systems such as small office buildings or retail spaces where cost savings are a priority. However, their durability may not meet the requirements of heavy-use systems. - Brass in Commercial Plumbing

Brass fittings excel in commercial plumbing due to their resilience under high pressures and temperatures. Hotels, hospitals, and industrial facilities commonly use them where water systems are in constant operation.

Scenario Example: A hotel’s plumbing system would use brass fittings to handle high-temperature water and constant usage, while a small retail store could use poly alloy fittings for budget efficiency.

Outdoor and High-Temperature Applications

Outdoor and high-temperature plumbing systems place unique demands on fittings, making brass the superior choice in most cases.

- Poly Alloy in Outdoor Applications

Poly alloy fittings are less suited for outdoor use due to their sensitivity to UV rays and temperature extremes. If used outdoors, they must be adequately protected to prevent degradation. - Brass in Outdoor and High-Temperature Systems

Brass fittings are highly durable and perform well in both freezing and scorching conditions. They are ideal for outdoor plumbing, irrigation systems, and high-temperature applications such as solar water heaters.

Scenario Example: A garden irrigation system would benefit from brass fittings for their ability to resist corrosion and withstand varying weather conditions.

Environmental Considerations

Sustainability of Poly Alloy

Poly alloy fittings are a lightweight option, which reduces transportation emissions. However, they are not as easily recyclable as brass, and their production involves petrochemical materials, which have a higher environmental footprint.

Advantages of Poly Alloy Sustainability:

- Reduced shipping weight decreases carbon emissions.

- Durable under most conditions, reducing waste.

Limitations:

- Limited recyclability compared to brass.

- Dependency on fossil fuels for manufacturing.

Brass Recycling and Reusability

Advantages of Brass Sustainability:

- 100% recyclable, lowering environmental impact.

- Long lifespan reduces the frequency of replacements.

- Often made from partially recycled materials.

Limitations:

- Heavier weight increases shipping-related emissions.

- Initial extraction of copper and zinc can be resource-intensive.

Which Is More Sustainable?

If sustainability is a priority, brass fittings are the better option due to their recyclability and longevity, despite their higher upfront cost.

How to Choose the Right PEX Fitting

Factors to Consider

When selecting between poly alloy and brass PEX fittings, keep the following factors in mind:

- Cost: Poly alloy fittings are more affordable upfront, making them suitable for budget-conscious projects.

- Durability: Brass is the better option for long-term performance and in systems exposed to high pressures or temperatures.

- Water Quality: If your water is highly corrosive (e.g., high chlorine levels), poly alloy fittings may be a better choice.

Evaluating Water Conditions

Understanding the water conditions in your area is crucial:

- Corrosive Water: Use poly alloy fittings to prevent rust and degradation.

- Neutral Water Quality: Brass fittings provide excellent durability and lifespan in areas with neutral water chemistry.

Budget and Longevity Balance

Consider the trade-offs between upfront costs and long-term value:

- For a lower initial investment, poly alloy fittings are an economical choice.

- For systems where longevity and minimal maintenance are priorities, brass fittings offer superior value despite their higher cost.

Conclusion

Both poly alloy and brass PEX fittings offer unique advantages and are suited for specific applications. Poly alloy fittings are cost-effective, lightweight, and corrosion-resistant, making them ideal for residential systems with low to moderate demands. Brass fittings, on the other hand, excel in durability, temperature resistance, and long-term performance, making them the best choice for high-demand, commercial, and outdoor systems.

Your decision should ultimately be based on the specific requirements of your plumbing system, including water quality, temperature ranges, and budget.

FAQs

1. Are poly alloy fittings more cost-effective than brass?

Yes, poly alloy fittings are generally more affordable upfront. They are an excellent choice for residential systems where cost savings are a priority.

2. Can brass fittings be used in corrosive environments?

Brass fittings can corrode in environments with high chlorine or sulfide levels. For such conditions, poly alloy fittings may be a better option.

3. Do poly alloy fittings meet all PEX plumbing codes?

Yes, poly alloy fittings are certified to meet ASTM F2159 standards and are widely accepted in plumbing systems for potable water use.

4. Which fitting type lasts longer in residential plumbing?

Brass fittings typically last longer, often 20–50 years, compared to poly alloy fittings, which may need replacement after 10–15 years.

5. How do I ensure compatibility between fittings and PEX tubing?

Ensure both the fittings and tubing meet the same certification standards (e.g., ASTM F2159 for poly alloy and ASTM F1807 for brass).

6. Can I mix brass and poly alloy fittings in the same system?

Yes, you can mix both types in a single system as long as the water quality and pressure conditions are suitable for both materials.