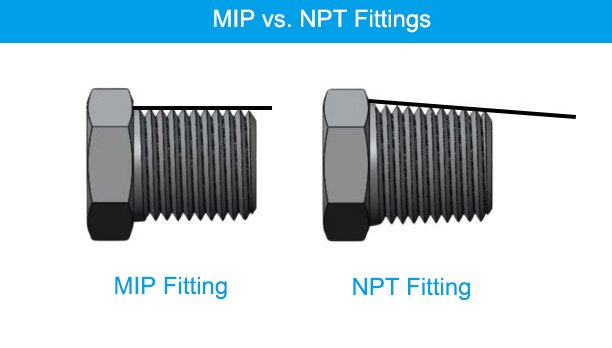

MIP and NPT Fittings

In the world of plumbing and industrial piping, selecting the right fittings is crucial. MIP (Male Iron Pipe) and NPT (National Pipe Taper) fittings are two widely used types of threaded connectors, each designed for different applications. Understanding the key differences between MIP and NPT fittings ensures that you can make informed decisions, whether you’re working on a high-pressure industrial system or a low-pressure residential installation.

The Importance of Understanding Pipe Fittings

Why Pipe Fittings Matter

Pipe fittings are crucial for ensuring secure, leak-proof connections in any plumbing or piping system. Choosing the wrong fitting can lead to serious issues such as leaks, pressure drops, or even complete system failures. For example, using a fitting that can’t handle the required pressure can cause dangerous bursts. Understanding the specific characteristics of MIP (Male Iron Pipe) and NPT fittings is key to maintaining system integrity and preventing these problems.

Common Types of Pipe Fittings in the Industry

There are various types of pipe fittings, including elbows, tees, couplings, and valves, each serving a specific purpose. Among these, MIP fittings and NPT fittings are especially important for threaded connections. MIP fittings, which stand for Male Iron Pipe, are commonly used in high-pressure industrial environments, while NPT fittings are versatile and often found in residential plumbing systems. Knowing the meaning of MIP, understanding MIP threads, and recognizing when to use MIP versus NPT fittings are vital for ensuring a successful installation and maintaining the safety and efficiency of your piping system.

Definition of MIP and NPT Fittings

MIP (Male Iron Pipe) Fittings

MIP fittings are a type of NPT fitting, specifically designed with male threads that screw into female threads on a pipe or fitting. Both MIP and NPT threads are cut at a 60° angle, ensuring compatibility with most pipes adhering to the NPT standard.

- MIP fittings are usually made from durable metals like iron, steel, or brass, making them ideal for high-pressure applications.

- These fittings come in various sizes, and measuring the thread pitch (Threads Per Inch, or TPI) is crucial for ensuring a proper fit.

NPT (National Pipe Taper) Fittings

NPT fittings are the U.S. standard for threaded pipe connections. The defining feature of NPT fittings is their tapered threads, which decrease in diameter toward the end of the fitting. This tapering creates a tighter seal as the fitting is screwed into a corresponding female thread, making NPT fittings ideal for preventing leaks.

- NPT fittings are often made from plastic, such as PVC, but they can also be metal. The material chosen typically depends on the application—whether it’s a low-pressure residential system or a more demanding setting.

Fitting Type and Connection

Compatibility with Female Ports

MIP fittings connect with FIP (Female Iron Pipe) ports, while NPT fittings connect with FNPT (Female National Pipe Taper) ports. Ensuring that the male and female threads are compatible is crucial for a secure connection. Although MIP and NPT fittings share similarities, they are optimized for use with their respective female counterparts.

Connection Method

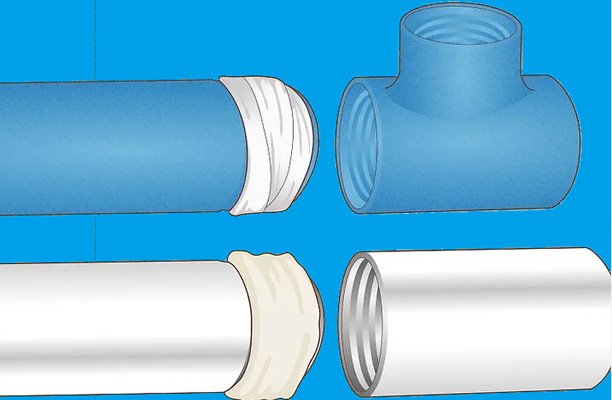

When connecting MIP or NPT fittings, proper technique is crucial to ensuring a leak-free joint. Here’s a step-by-step guide:

- Prepare the Threads: Ensure both the male and female threads are clean and free from debris. Use a wire brush to remove any old sealant or dirt.

- Apply Sealant: For NPT fittings, wrap the male threads with Teflon tape, ensuring you wrap in the direction of the threads (clockwise) to prevent the tape from unraveling during installation. For MIP fittings, apply a generous amount of pipe dope on the threads, making sure it’s evenly spread.

- Tighten the Fitting: Begin threading the male fitting into the female port by hand to avoid cross-threading. Once it’s hand-tight, use a pipe wrench to further tighten the connection. Be careful not to overtighten, as this can damage the threads and compromise the seal.

- Test for Leaks: After installation, it’s essential to test the connection for leaks. For water systems, slowly turn on the water supply and inspect the joint for any drips. For gas lines, use a soap and water mixture and watch for bubbles indicating a leak.

Application Scenarios

High-Pressure vs. Low-Pressure Systems

High-Pressure Systems (MIP Fittings):

- Industrial Manufacturing: Systems that transport high-pressure steam, chemicals, or gases commonly use MIP fittings. For example, a refinery might use MIP fittings in the piping systems that handle corrosive chemicals at high pressures.

- Hydraulic Systems: These hydraulic fittings are also used in hydraulic systems, where the pressure can exceed several thousand PSI. The strength of the metal and the reliability of the connection are crucial in these scenarios.

Low-Pressure Systems (NPT Fittings):

- Residential Plumbing: NPT fittings are ubiquitous in residential plumbing, especially for water supply lines, gas lines, and irrigation systems. For instance, the pipes leading to your kitchen sink or outdoor sprinkler system likely use NPT fittings.

- HVAC Systems: NPT fittings are also used in HVAC systems, where they connect various components like air ducts and gas supply lines. The low-pressure nature of these systems makes NPT fittings an ideal choice.

Material Composition

Material of MIP Fittings

MIP fittings generally use metals such as iron, copper, steel, or brass. Manufacturers choose these materials for their strength and ability to withstand high pressures and harsh conditions typically found in industrial settings. The metal construction allows MIP fittings to endure significant wear and tear over time.

Material of NPT Fittings

NPT fittings are available in both metal and plastic materials. Common options include brass, stainless steel, aluminum, PVC, and CPVC. The specific application determines the material choice. For instance, plumbers often use PVC for water supply lines in residential settings, while they choose brass or stainless steel for more demanding applications.

Shape and Thread Design

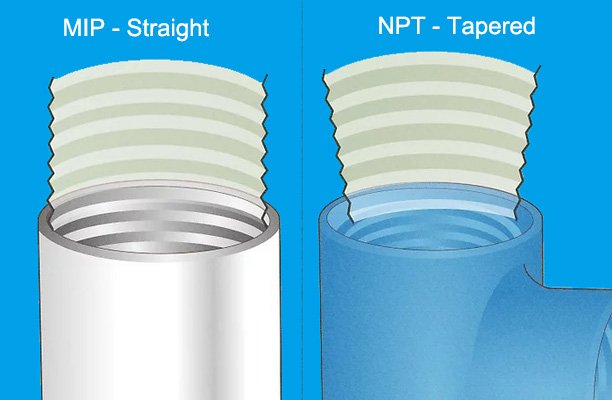

Tapered vs. Straight Threads

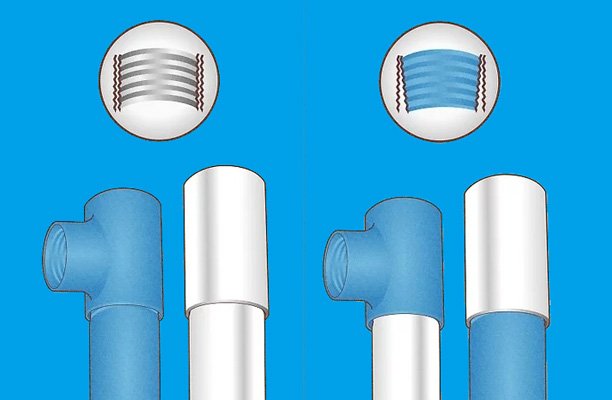

One of the key differences between MIP and NPT fittings is the shape of their threads. NPT fittings have tapered threads, which help create a tighter seal as they are screwed into a corresponding female port, reducing the risk of leaks. In contrast, MIP fittings usually have straight threads, which may require additional sealing methods, like pipe dope or Teflon tape, to ensure a leak-proof joint.

Sealing Effectiveness

The thread shape plays a critical role in sealing effectiveness. Tapered threads in NPT fittings naturally create a tighter seal, which is ideal for preventing leaks. Straight threads in MIP fittings, while still effective, often need extra sealing measures to achieve the same level of leak prevention.

Sealant Use

Sealants for NPT Fittings

NPT fittings are typically sealed with Teflon tape, also known as PTFE tape. They wrap this tape around the threads before installing the fitting, which fills any gaps and ensures a more secure seal. Teflon tape proves particularly useful in applications where the fitting will face fluids or gases under pressure.

Sealants for MIP Fittings

MIP fittings are often sealed with pipe dope, a paste-like sealant that is applied to the threads before installation. Pipe dope provides a strong, durable seal that can withstand high pressures and temperatures, making it well-suited for metal fittings in industrial applications.

Compatibility and Interchangeability

Compatibility of Threads

While MIP and NPT threads share a similar 60° thread angle, they are not fully interchangeable with other thread standards, such as BSPT (British Standard Pipe Taper) or BSPP (British Standard Pipe Parallel). Ensuring that the threads of the male and female fittings are compatible is crucial for avoiding leaks and potential system failures.

Troubleshooting Common Issues with MIP and NPT Fittings

Even with proper installation, issues can arise with MIP and NPT fittings. Here’s how to troubleshoot some of the most common problems:

- Leaking Joints: If you notice a leak, the first step is to check the tightness of the connection. If the fitting is not sufficiently tight, it may need to be adjusted. However, avoid over tightening as this can strip the threads or crack the fitting. If the leak persists, disassemble the joint, clean the threads, apply fresh sealant, and reassemble.

- Cross-Threading: Cross-threading occurs when the threads do not align properly, leading to a poor connection. To avoid this, always start threading the fitting by hand. If cross-threading has occurred, you may need to replace the fitting, as forcing it could damage both the fitting and the pipe.

- Cracked Fittings: Over-tightening, using the wrong type of fitting for the application, or using a low-quality fitting can lead to cracks. Inspect fittings regularly for signs of wear and tear, and replace any that show signs of cracking.

- Sealant Failure: Sometimes, the sealant itself can fail, especially if the wrong type was used or if it was applied incorrectly. If you suspect sealant failure, disassemble the joint, clean off the old sealant, and reapply the correct type before reassembling.

Environmental and Regulatory Considerations

In many industries, the choice of fittings is influenced not just by technical requirements but also by environmental and regulatory standards. Here’s how these considerations impact the use of MIP and NPT fittings:

- Material Compliance: In industries such as food processing or pharmaceuticals, fittings must often comply with specific regulations regarding material safety. For instance, applications that involve contact with consumables may require stainless steel MIP fittings, as they resist corrosion and are easy to sanitize.

- Pressure and Temperature Standards: Regulatory bodies often set standards for the pressure and temperature ratings of fittings used in certain applications. In industrial settings, professionals often prefer MIP fittings for their higher pressure ratings and ability to withstand extreme temperatures, ensuring they meet safety standards.

- Environmental Impact: In environmentally sensitive applications, such as those involving the transport of hazardous materials, the choice of fitting material and design can impact leak prevention and environmental safety. You can use NPT fittings made from environmentally friendly materials, like certain plastics, in non-critical, low-pressure applications. This choice helps reduce environmental impact.

- Industry-Specific Regulations: Different industries have specific regulations governing the types of fittings that can be used. For example, the oil and gas industry may have strict requirements for the use of metal fittings like MIP, due to the high pressures and potential for corrosive materials involved.

Conclusion

MIP vs NPT Fittings: Key Differences

In summary, MIP and NPT fittings are essential components in different applications, each with its distinct advantages:

- NPT threads are the national U.S. standard for pipe fittings, commonly used in residential plumbing for low-pressure systems. They use tapered threads, typically crafted from plastic materials such as PVC, which form a tighter seal when screwed in.

- MIP fittings are a specific type of NPT thread, typically employed in high-pressure industrial applications due to their durable metal construction. These fittings have straight threads that are consistent in width from top to bottom, often requiring additional sealing techniques to ensure a leak-proof connection.

Understanding these differences in thread design, material composition, and sealing requirements is crucial for selecting the right fitting for your needs.

Importance of Quality

Regardless of whether you choose MIP or NPT fittings, prioritizing quality is essential. High-quality fittings made from durable materials will ensure the long-term integrity of your system, reducing the risk of leaks, failures, and costly repairs. By investing in the right fittings, you can guarantee the safety and efficiency of your plumbing or piping system.

FAQs

What are the Main Differences of MIP vs NPT Fittings?

MIP fittings have straight threads and are used in high-pressure industrial systems, while NPT fittings have tapered threads and are more commonly used in low-pressure residential systems.

Can MIP and NPT Fittings be Interchanged?

MIP and NPT fittings can sometimes be used together, but they are not fully interchangeable with other thread standards like BSPT or BSPP.

Tips for Preventing Leaks During Installation?

To prevent leaks, ensure the threads are clean and free of debris. Use the appropriate sealant (Teflon tape or pipe dope) and tighten the fitting to the recommended torque.

How to Identify Signs of Wear and Tear in Pipe Fittings?

Look for visible signs of corrosion, cracks, or deformed threads. Leaks or pressure drops can also indicate that a fitting needs replacement.

Where to Find High-Quality MIP and NPT Fittings?

You can find high-quality MIP and NPT fittings at reputable plumbing supply stores, industrial suppliers, and online retailers. Look for trusted brands and durable materials.